(!)Due to Microsoft's end of support for Internet Explorer 11 on 15/06/2022, this site does not support the recommended environment.

Mon. - Fri. 8 a.m. - 6 p.m.

All Categories

-

Automation Components

Automation Components

Show all categories of Automation Components-

Linear Motion

-

Rotary Motion

-

Connecting Parts

-

Rotary Power Transmission

-

Motors

-

Conveyors & Material Handling

-

Locating, Positioning, Jigs & Fixtures

-

Inspection

-

Sensors, Switches

-

Pneumatics, Hydraulics

-

Vacuum Components

-

Hydraulic Equipment

-

Spray Equipment And Accessories

-

Pipe, Tubes, Hoses & Fittings

-

Modules, Units

-

Heaters, Temperature Control

-

Aluminum Extrusions, Framing, Support & Posts

-

Casters, Leveling Mounts, Posts

-

Doors, Cabinet Hardware

-

Springs, Shock Absorbers

-

Adjustment/Fastening Components, Pins, Magnets

-

Antivibration, Soundproofing Materials, Safety Products

-

- Fasteners

- Materials

-

Wiring Components

Wiring Components

Show all categories of Wiring Components-

LAN Cables / Industrial Network Cables

-

Equipment Specific Cables

-

Cordsets

-

Computer & AV Cables

-

Wire/Cable

-

Connector (General Purpose)

-

Crimp Terminal Components

-

Cable Organization

-

Cable Gland Components

-

Cable Bushing/Clip/Sticker

-

Screw/Spacer

-

Cable accessories

-

Tube

-

Electrical Conduits

-

Duct/Wiring

-

Electrical Wiring Tools

-

Dedicated tools

-

Soldering supplies

-

- Electrical & Controls

-

Cutting Tools

Cutting Tools

Show all categories of Cutting Tools-

Carbide End Mill

-

HSS End Mill

-

Concrete Drill Bits

-

Milling Cutter Insert / Holder

-

Core Drill Bits

-

Customized Straight Blade End Mill

-

Dedicated Cutter

-

Crinkey Cutters

-

Turning Tool

-

Drill

-

Cutting Tool Accessories

-

Screw Hole Related Tools

-

Reamer

-

Electric Drill Bits

-

Chamfering, Centering Tool

-

Hole Saws

-

Magnetic Drill Press Cutters

-

Step Drills

-

Wood Drills & Cutters

-

-

Processing Tools

-

Packing & Logistics Storage Supplies

- Safety Products

-

Research and Development & Cleanroom Supplies

Research and Development & Cleanroom Supplies

Show all categories of Research and Development & Cleanroom Supplies - Press Die Components

-

Plastic Mold Components

Plastic Mold Components

Show all categories of Plastic Mold Components-

Ejector Pins

-

Sleeves, Center Pins

-

Core Pins

-

Sprue bushings, Gates, and other components

-

Date Mark Inserts, Recycle Mark Inserts, Pins with Gas Vent

-

Undercut, Plates

-

Leader Components, Components for Ejector Space

-

Mold Opening Controllers

-

Cooling or Heating Components

-

Accessories, Others

-

Components of Large Mold, Die Casting

-

-

Injection Molding Components

Injection Molding Components

Show all categories of Injection Molding Components-

Purging Agent

-

Injection Molding Machine Products

-

Accessories of Equipment

-

Auxiliary Equipment

-

Air Nippers

-

Air Cylinders

-

Air Chuck for Runner

-

Chuck Board Components

-

Frames

-

Suction Components

-

Parallel Air Chuck

-

Special Air Chuck

-

Mold Maintenance

-

Heating Items

-

Heat Insulation Sheets

-

Couplers, Plugs, One-touch Joints

-

Tubes, Hoses, Peripheral Components

-

- Webcode Seach | Series

-

#CODE

- Discontinued Products

Loading...

- inCAD Library Home

- > No.000042 Manually Indexed Rotary Table

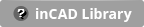

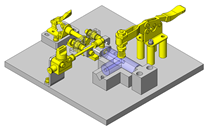

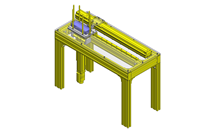

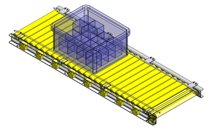

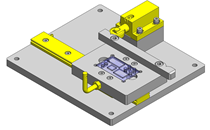

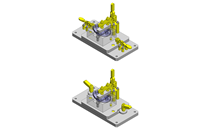

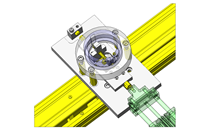

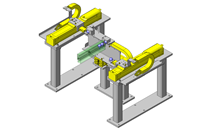

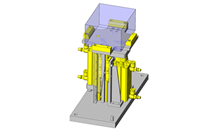

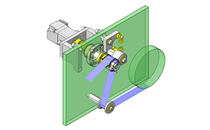

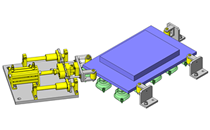

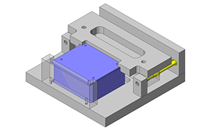

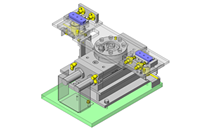

No.000042 Manually Indexed Rotary Table

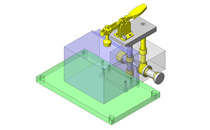

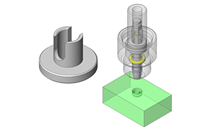

Ball Buttons are used to prevent wear on the outside of the housing.

Relevant category

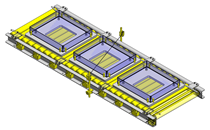

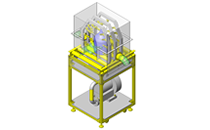

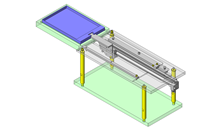

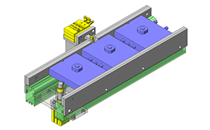

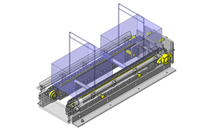

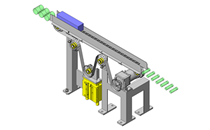

- * Unit assembly Data consists of some sub-assemblies.

It is configured so that each sub-assembly unit can be used as it is or edited.

Application Overview

Purpose

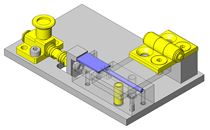

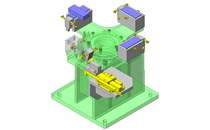

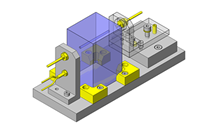

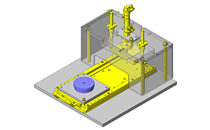

- A manually indexed rotary table using a ball plunger and ball buttons.

- Used for inspecting specific locations on a component with microscope.

Target workpiece

- Plastic case

Case dimensions: φ110 H20

Design Specifications

Operating Conditions or Design Requirements

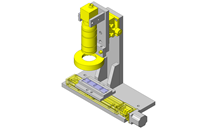

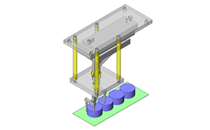

- External dims.: W100 x L170 x H129

- Table O.D.: 120

Required Performance

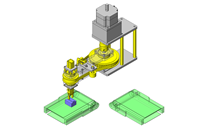

- Retaining force that withstands 10N of external force applied.

Selection Criteria for Main Components

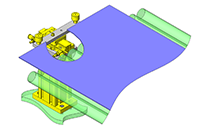

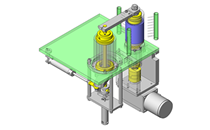

- For ease of adjustment, Long Ball Plunger is used in this application.

Design Evaluation

Verification of main components

- Select a ball plunger capable of retaining a workpiece.

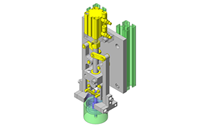

- Ball plunger retention force calculations

- V groove angle of the ball button is 45 degrees per side, and plunger setting load and operation force are the same.

The retaining force with plunger setup for 0.078mm stroke (almost zero touch) is

0.99N + 6.9N = 7.9N - Max. force to overcome the V groove is at the plunger stroke 0.75mm,

9.525N+6.9N=16.425N - Distance from ball button groove edge to the rotation center is approx. 53mm,so the torque that it takes to overcome the V groove is approx. 16.425 × 0.053 = 0.87N・m (Actually a little more due to friction)

When an external force 1.0kg (10N) applies to the center of handle (80mm from the center of rotation), the torque is 0.8N・m

⇒ BPJL8 where the retention force covers the load value is selected.

- V groove angle of the ball button is 45 degrees per side, and plunger setting load and operation force are the same.

Other Design Consideration

- A bearing holder is used to retain rotation.

Explore Similar Application Examples

-

Relevant category

-

Relevant category

-

Relevant category