(!)Due to Microsoft's end of support for Internet Explorer 11 on 15/06/2022, this site does not support the recommended environment.

Mon. - Fri. 8 a.m. - 6 p.m.

All Categories

-

Automation Components

Automation Components

Show all categories of Automation Components-

Linear Motion

-

Rotary Motion

-

Connecting Parts

-

Rotary Power Transmission

-

Motors

-

Conveyors & Material Handling

-

Locating, Positioning, Jigs & Fixtures

-

Inspection

-

Sensors, Switches

-

Pneumatics, Hydraulics

-

Vacuum Components

-

Hydraulic Equipment

-

Spray Equipment And Accessories

-

Pipe, Tubes, Hoses & Fittings

-

Modules, Units

-

Heaters, Temperature Control

-

Aluminum Extrusions, Framing, Support & Posts

-

Casters, Leveling Mounts, Posts

-

Doors, Cabinet Hardware

-

Springs, Shock Absorbers

-

Adjustment/Fastening Components, Pins, Magnets

-

Antivibration, Soundproofing Materials, Safety Products

-

- Fasteners

- Materials

-

Wiring Components

Wiring Components

Show all categories of Wiring Components-

LAN Cables / Industrial Network Cables

-

Equipment Specific Cables

-

Cordsets

-

Computer & AV Cables

-

Wire/Cable

-

Connector (General Purpose)

-

Crimp Terminal Components

-

Cable Organization

-

Cable Gland Components

-

Cable Bushing/Clip/Sticker

-

Screw/Spacer

-

Cable accessories

-

Tube

-

Electrical Conduits

-

Duct/Wiring

-

Electrical Wiring Tools

-

Dedicated tools

-

Soldering supplies

-

- Electrical & Controls

-

Cutting Tools

Cutting Tools

Show all categories of Cutting Tools-

Carbide End Mill

-

HSS End Mill

-

Concrete Drill Bits

-

Milling Cutter Insert / Holder

-

Core Drill Bits

-

Customized Straight Blade End Mill

-

Dedicated Cutter

-

Crinkey Cutters

-

Turning Tool

-

Drill

-

Cutting Tool Accessories

-

Screw Hole Related Tools

-

Reamer

-

Electric Drill Bits

-

Chamfering, Centering Tool

-

Hole Saws

-

Magnetic Drill Press Cutters

-

Step Drills

-

Wood Drills & Cutters

-

-

Processing Tools

- Packing & Logistics Storage Supplies

- Safety Products

-

Research and Development & Cleanroom Supplies

Research and Development & Cleanroom Supplies

Show all categories of Research and Development & Cleanroom Supplies - Press Die Components

-

Plastic Mold Components

Plastic Mold Components

Show all categories of Plastic Mold Components-

Ejector Pins

-

Sleeves, Center Pins

-

Core Pins

-

Sprue bushings, Gates, and other components

-

Date Mark Inserts, Recycle Mark Inserts, Pins with Gas Vent

-

Undercut, Plates

-

Leader Components, Components for Ejector Space

-

Mold Opening Controllers

-

Cooling or Heating Components

-

Accessories, Others

-

Components of Large Mold, Die Casting

-

-

Injection Molding Components

Injection Molding Components

Show all categories of Injection Molding Components-

Purging Agent

-

Injection Molding Machine Products

-

Accessories of Equipment

-

Auxiliary Equipment

-

Air Nippers

-

Air Cylinders

-

Air Chuck for Runner

-

Chuck Board Components

-

Frames

-

Suction Components

-

Parallel Air Chuck

-

Special Air Chuck

-

Mold Maintenance

-

Heating Items

-

Heat Insulation Sheets

-

Couplers, Plugs, One-touch Joints

-

Tubes, Hoses, Peripheral Components

-

- Webcode Seach | Series

-

#CODE

- Discontinued Products

Loading...

- inCAD Library Home

- > No.000218 Fine Adjustment Mechanism Using Flat Springs

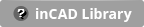

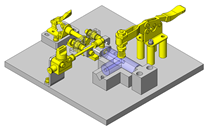

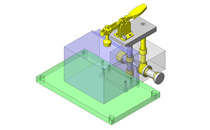

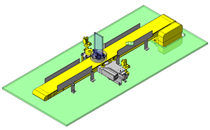

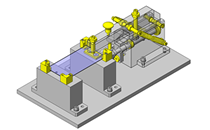

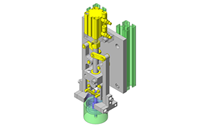

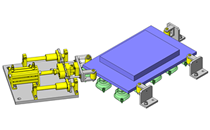

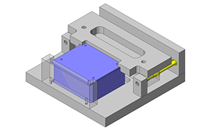

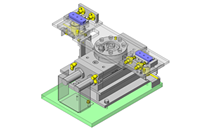

No.000218 Fine Adjustment Mechanism Using Flat Springs

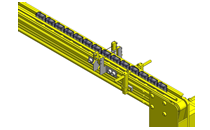

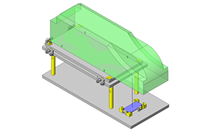

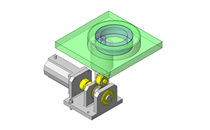

Slide Adjustment Utilizing Flat Spring

Relevant category

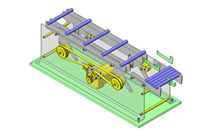

- * Unit assembly Data consists of some sub-assemblies.

It is configured so that each sub-assembly unit can be used as it is or edited.

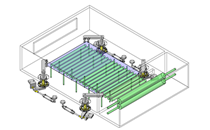

Application Overview

Purpose

- Purpose

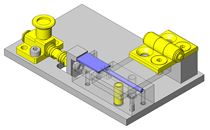

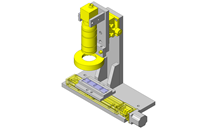

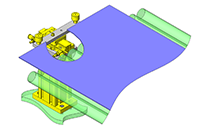

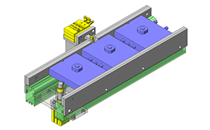

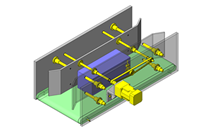

- To perform fine adjustment during product inspection without changing overall dimensions and layout of the fixture.

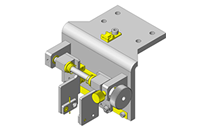

- Operation

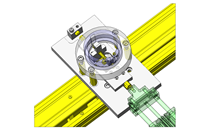

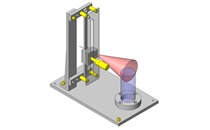

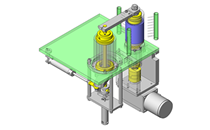

- By pressing the flat springs, which are installed at both ends of the slide shaft, from the outside using adjusting bolts, the slide shaft moves. Due to this movement, the optical axis of the inspection camera that is mounted onto strut clamp is adjusted.

After that, lock the position of the slide shaft by applying the adjusting screws to the flat springs from opposite direction.

- By pressing the flat springs, which are installed at both ends of the slide shaft, from the outside using adjusting bolts, the slide shaft moves. Due to this movement, the optical axis of the inspection camera that is mounted onto strut clamp is adjusted.

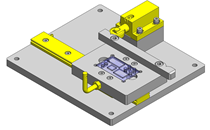

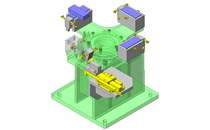

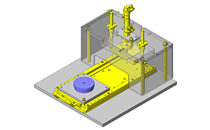

Target workpiece

- Shape: mounted circuit board

- Size: W80 x D80 x H12 mm

- Weight: 40 g

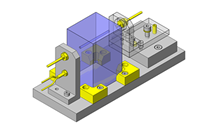

Design Specifications

Operating Conditions or Design Requirements

- Maximum fine adjustment amount: 1.6 mm

- Outer dimensions: W100 x D242 x H53 mm

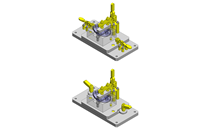

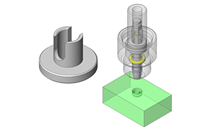

Selection Criteria for Main Components

- Select adjustment screws that can be used when the flat spring deflection is 1.6mm.

Design Evaluation

Verification of main components

- Verify that length of the adjusting bolts are sufficient to support all camera positions.

- Selection of stopper bolts

- Conditional value: arc length of flat spring (304 Stainless Steel) L1 = 49.5 mm, spring deflection limit σ = 275N/mm², Young's modulus of flat spring E = 186000N/mm², thickness of flat spring H = 1.0mm, arc length from flat spring fixing side to adjusting screw L2 = 24.75 mm, length from flat spring to plate for adjusting screw L3 = 11.1 mm, overall length of adjusting screw L4 = 30 mm, height of nut supplied with adjusting screw L5 = 4 mm

- If we assume that the arc-shaped flat spring is a straight line, the deflection σ2 when it is handled as a spring with one end fixed,

σ2=σ×L2²×(3×L1/L2-1)/(3×E×H)=275×24.75²×(3×49.5/24.75-1)/(3×186000×1.0)=1.51mm

⇒The length of adjusting screw that can perform adjustment even when the flat spring deflects for 1.51mm is

range satisfying 1.51 + L3 < L4 - L5

1.51+11.1<30-5.4

⇒30mm, hence, selected adjusting stopper screw is acceptable for this application.

Other Design Consideration

- When a flat spring is being adjusted using an adjusting screw on one end, the adjusting screw on the other end should not be in contact with the flat spring.

Explore Similar Application Examples

-

Relevant category

-

Relevant category

-

Relevant category