(!)Due to Microsoft's end of support for Internet Explorer 11 on 15/06/2022, this site does not support the recommended environment.

Mon. - Fri. 8 a.m. - 6 p.m.

All Categories

-

Automation Components

Automation Components

Show all categories of Automation Components-

Linear Motion

-

Rotary Motion

-

Connecting Parts

-

Rotary Power Transmission

-

Motors

-

Conveyors & Material Handling

-

Locating, Positioning, Jigs & Fixtures

-

Inspection

-

Sensors, Switches

-

Pneumatics, Hydraulics

-

Vacuum Components

-

Hydraulic Equipment

-

Spray Equipment And Accessories

-

Pipe, Tubes, Hoses & Fittings

-

Modules, Units

-

Heaters, Temperature Control

-

Aluminum Extrusions, Framing, Support & Posts

-

Casters, Leveling Mounts, Posts

-

Doors, Cabinet Hardware

-

Springs, Shock Absorbers

-

Adjustment/Fastening Components, Pins, Magnets

-

Antivibration, Soundproofing Materials, Safety Products

-

- Fasteners

- Materials

-

Wiring Components

Wiring Components

Show all categories of Wiring Components-

LAN Cables / Industrial Network Cables

-

Equipment Specific Cables

-

Cordsets

-

Computer & AV Cables

-

Wire/Cable

-

Connector (General Purpose)

-

Crimp Terminal Components

-

Cable Organization

-

Cable Gland Components

-

Cable Bushing/Clip/Sticker

-

Screw/Spacer

-

Cable accessories

-

Tube

-

Electrical Conduits

-

Duct/Wiring

-

Electrical Wiring Tools

-

Dedicated tools

-

Soldering supplies

-

- Electrical & Controls

-

Cutting Tools

Cutting Tools

Show all categories of Cutting Tools-

Carbide End Mill

-

HSS End Mill

-

Concrete Drill Bits

-

Milling Cutter Insert / Holder

-

Core Drill Bits

-

Customized Straight Blade End Mill

-

Dedicated Cutter

-

Crinkey Cutters

-

Turning Tool

-

Drill

-

Cutting Tool Accessories

-

Screw Hole Related Tools

-

Reamer

-

Electric Drill Bits

-

Chamfering, Centering Tool

-

Hole Saws

-

Magnetic Drill Press Cutters

-

Step Drills

-

Wood Drills & Cutters

-

-

Processing Tools

- Packing & Logistics Storage Supplies

- Safety Products

-

Research and Development & Cleanroom Supplies

Research and Development & Cleanroom Supplies

Show all categories of Research and Development & Cleanroom Supplies - Press Die Components

-

Plastic Mold Components

Plastic Mold Components

Show all categories of Plastic Mold Components-

Ejector Pins

-

Sleeves, Center Pins

-

Core Pins

-

Sprue bushings, Gates, and other components

-

Date Mark Inserts, Recycle Mark Inserts, Pins with Gas Vent

-

Undercut, Plates

-

Leader Components, Components for Ejector Space

-

Mold Opening Controllers

-

Cooling or Heating Components

-

Accessories, Others

-

Components of Large Mold, Die Casting

-

-

Injection Molding Components

Injection Molding Components

Show all categories of Injection Molding Components-

Purging Agent

-

Injection Molding Machine Products

-

Accessories of Equipment

-

Auxiliary Equipment

-

Air Nippers

-

Air Cylinders

-

Air Chuck for Runner

-

Chuck Board Components

-

Frames

-

Suction Components

-

Parallel Air Chuck

-

Special Air Chuck

-

Mold Maintenance

-

Heating Items

-

Heat Insulation Sheets

-

Couplers, Plugs, One-touch Joints

-

Tubes, Hoses, Peripheral Components

-

- Webcode Seach | Series

-

#CODE

- Discontinued Products

Loading...

- inCAD Library Home

- > No.000266 Glass Circuit Board Conveyor

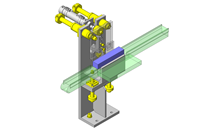

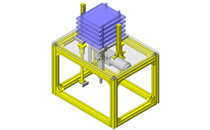

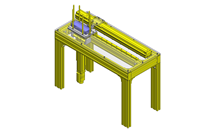

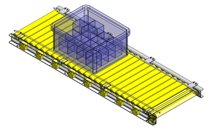

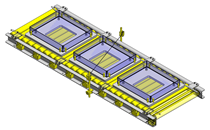

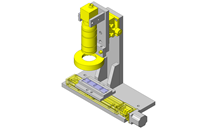

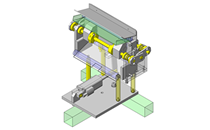

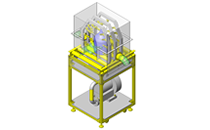

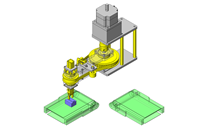

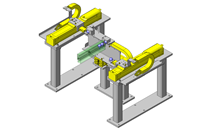

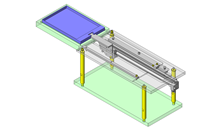

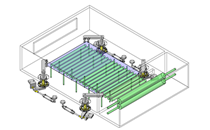

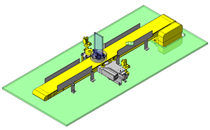

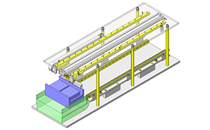

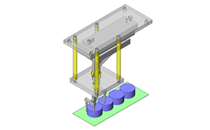

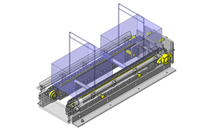

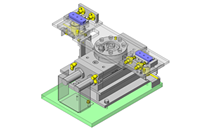

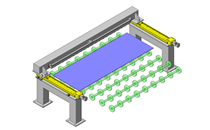

No.000266 Glass Circuit Board Conveyor

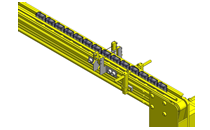

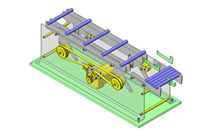

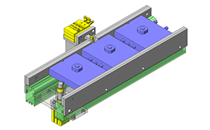

Motor driven conveying system using a system of rollers, pulleys, and belts.

Relevant category

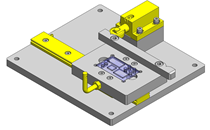

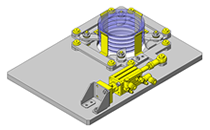

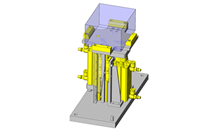

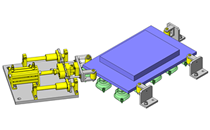

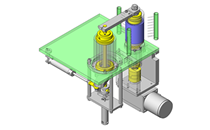

- * Unit assembly Data consists of some sub-assemblies.

It is configured so that each sub-assembly unit can be used as it is or edited.

Application Overview

Purpose

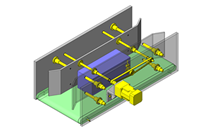

- Purpose: transferring glass circuit boards.

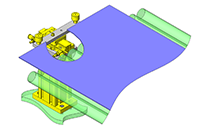

Operation: Rollers are each attached with an O-ring for proper contact with the sides and edges of the glass circuit boards.

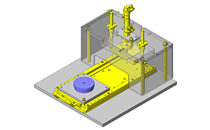

Target workpiece

- Shape: glass circuit board

- Size: t0.5 x W300 x D500mm

Design Specifications

Operating Conditions or Design Requirements

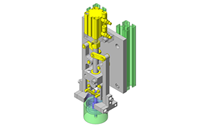

- Outer dimensions: W1200 x D714 x H280mm

- Transfer speed: 100mm/s

Required Performance

- Load: workpiece + belt = 50N

- Widthwise positioning accuracy: ±1mm

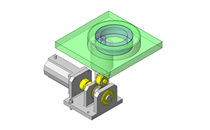

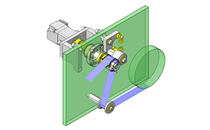

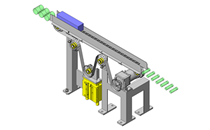

Selection Criteria for Main Components

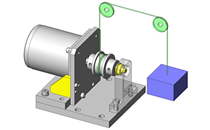

- A motor that can transfer a load of 50N at a speed of over 70mm/s is selected.

Design Evaluation

Verification of main components

- The torque of the motor and reducer is verified based on the load torque.

- Conditional value: pulley diameter D = 0.039m, friction coefficient μ = 0.3, efficiency η = 0.9, gear head efficiency ηG = 0.5, gear ratio G = 81, motor torque TM = 0.32N·m, motor rated rotation speed N = 3000rpm, load M = 50N

- Load torque: T = F x D/2 x η = μ x M x D/2 x η = 0.3 x 50 x 0.039/2 x 0.9 = 0.33N·m

- Torque of motor and reducer: G = TM x G x ηG = 0.32 x 81 x 0.5 = 13N·m

> 0.33N·m = T

-> There is no problem. - Transfer speed: V = N x D x π/G x 60 = 3000 x 39 x π/81 x 60 = 75.6mm/s

Other Design Consideration

- The conveying system is driven by a single motor.

- An adhesive rubber roller is installed for dust removal.

Explore Similar Application Examples

-

Relevant category

-

Relevant category