(!)Due to Microsoft's end of support for Internet Explorer 11 on 15/06/2022, this site does not support the recommended environment.

Our Business Hours:

Mon. - Fri. 8 a.m. - 6 p.m.

Mon. - Fri. 8 a.m. - 6 p.m.

All Categories

Categories

- Automation Components

- Linear Motion

- Rotary Motion

- Connecting Parts

- Rotary Power Transmission

- Motors

- Conveyors & Material Handling

- Locating, Positioning, Jigs & Fixtures

- Inspection

- Sensors, Switches

- Pneumatics, Hydraulics

- Vacuum Components

- Hydraulic Equipment

- Spray Equipment And Accessories

- Pipe, Tubes, Hoses & Fittings

- Modules, Units

- Heaters, Temperature Control

- Aluminum Extrusions, Framing, Support & Posts

- Casters, Leveling Mounts, Posts

- Doors, Cabinet Hardware

- Springs, Shock Absorbers

- Adjustment/Fastening Components, Pins, Magnets

- Antivibration, Soundproofing Materials, Safety Products

- Fasteners

- Materials

- Wiring Components

- LAN Cables / Industrial Network Cables

- Equipment Specific Cables

- Cordsets

- Computer & AV Cables

- Wire/Cable

- Connector (General Purpose)

- Crimp Terminal Components

- Cable Organization

- Cable Gland Components

- Cable Bushing/Clip/Sticker

- Screw/Spacer

- Cable accessories

- Tube

- Electrical Conduits

- Duct/Wiring

- Electrical Wiring Tools

- Dedicated tools

- Soldering supplies

- Electrical & Controls

- Cutting Tools

- Carbide End Mill

- HSS End Mill

- Concrete Drill Bits

- Milling Cutter Insert / Holder

- Core Drill Bits

- Customized Straight Blade End Mill

- Dedicated Cutter

- Crinkey Cutters

- Turning Tool

- Drill

- Cutting Tool Accessories

- Screw Hole Related Tools

- Reamer

- Electric Drill Bits

- Chamfering, Centering Tool

- Hole Saws

- Magnetic Drill Press Cutters

- Step Drills

- Wood Drills & Cutters

- Processing Tools

- packing & logistics storage supplies

- Safety Products

- research and development & cleanroom supplies

- Press Die Components

- Plastic Mold Components

- Ejector Pins

- Sleeves, Center Pins

- Core Pins

- Sprue bushings, Gates, and other components

- Date Mark Inserts, Recycle Mark Inserts, Pins with Gas Vent

- Undercut, Plates

- Leader Components, Components for Ejector Space

- Mold Opening Controllers

- Cooling or Heating Components

- Accessories, Others

- Components of Large Mold, Die Casting

- Injection Molding Components

- Purging Agent

- Injection Molding Machine Products

- Accessories of Equipment

- Auxiliary Equipment

- Air Nippers

- Air Cylinders

- Air Chuck for Runner

- Chuck Board Components

- Frames

- Suction Components

- Parallel Air Chuck

- Special Air Chuck

- Mold Maintenance

- Heating Items

- Heat Insulation Sheets

- Couplers, Plugs, One-touch Joints

- Tubes, Hoses, Peripheral Components

Applications

Brands

- inCAD Library Home

- > No.000301 Width Change Mechanism

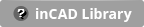

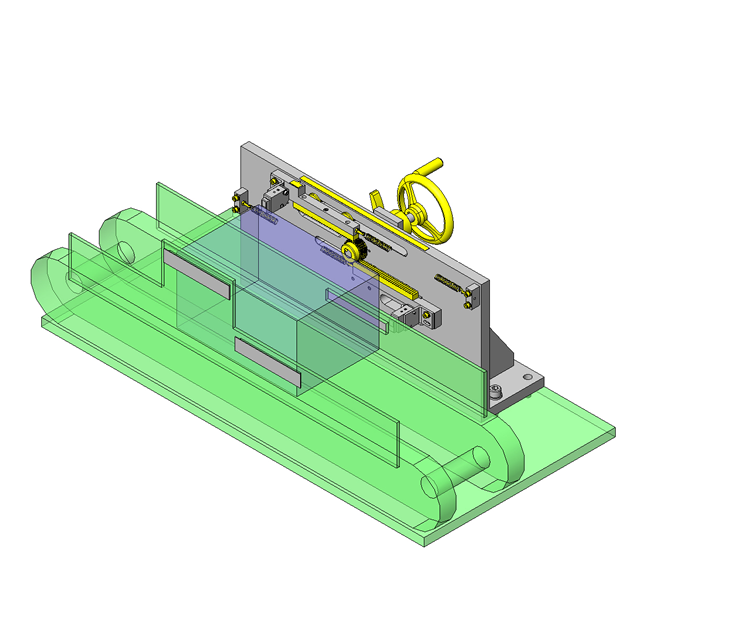

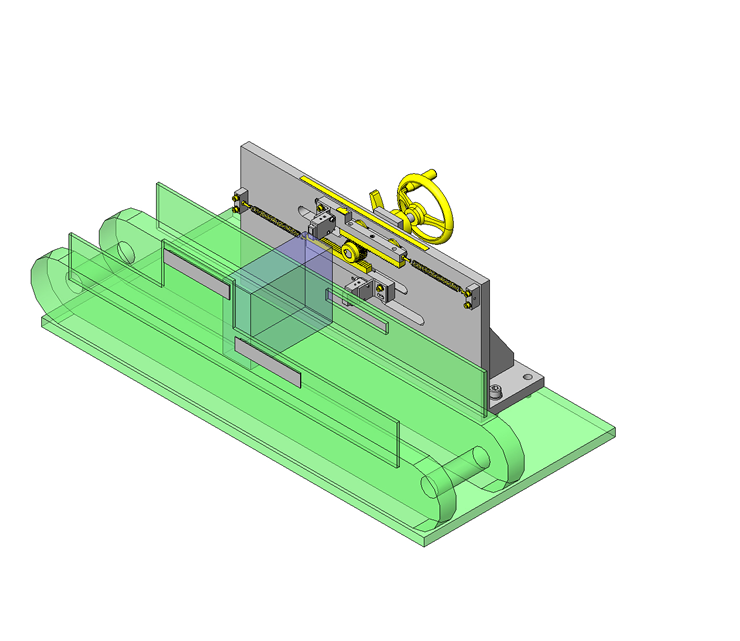

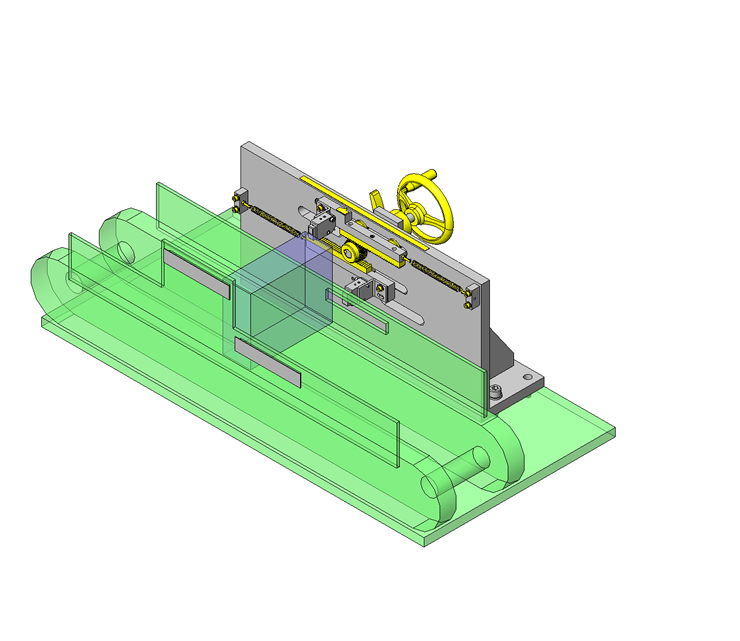

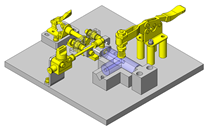

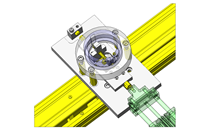

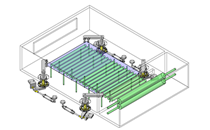

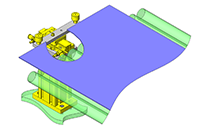

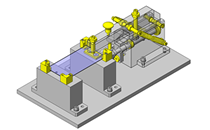

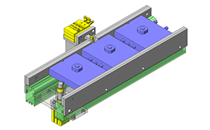

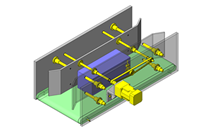

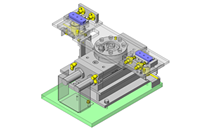

No.000301 Width Change Mechanism

Right and left movement synchronization using center of the workpiece as the reference

Relevant category

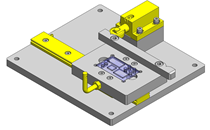

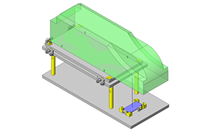

- * Unit assembly Data consists of some sub-assemblies.

It is configured so that each sub-assembly unit can be used as it is or edited.

Application Overview

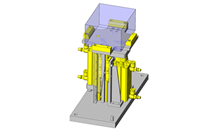

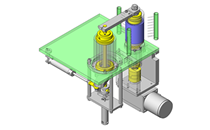

Purpose

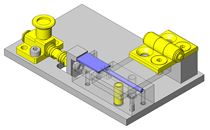

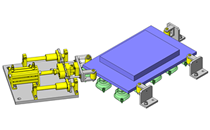

- The sensor position is set up based on the size of the workpiece. (confirmation of the transferred workpiece width)

- Confirm the size of the workpiece based on values on the scale plate. (Example: Applicable to workpiece A when the scale is 10mm)

- Width of workpiece is changed equal from both sides (left and right) using center of the workpiece as the reference.

- The backlash is reduced using tensile springs.

Points for use

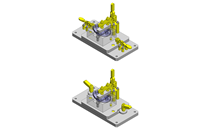

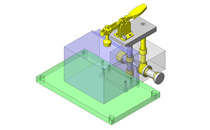

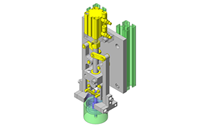

- A handle is used for adjustment, and rotation is stopped using a shaft collar.

- A retro-reflective type is used for the sensor.

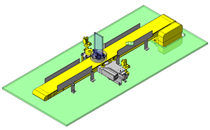

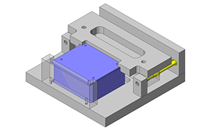

Target workpiece

- Plastic BOX

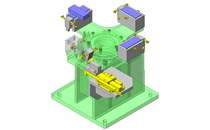

- Outer shape of large workpiece: W220xD150xH120mm

- Outer shape of small workpiece: W50xD150xH120mm

Design Specifications

Operating Conditions or Design Requirements

- External Dimensions: W440xD350xH219mm

- One side preparation stroke: 85mm

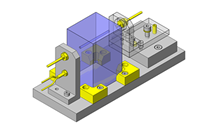

Selection Criteria for Main Components

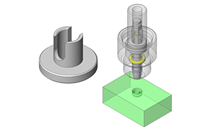

- Shaft collar

- Selected as "fixed" after an adjustment.

- Handle

- A handle which allows easy adjustment is selected.

- Tensile Springs

- Selected to reduce backlash.

- Rack Gear

- Two sections are selected to achieve synchronization.

Design Evaluation

Verification of main components

- The maximum distortion of a spring is verified based on the load conditions.

- Spring Load

- (i) When minimum width is set.

- Conditional Values: Initial tension 3.43N, Deflection when tensile is expected x=0mm.

- Formula: Based on reaction force F=kx+Initial tension, F=3.43N

(ii) When maximum width is set. - Formula: Reaction force F=kx+Initial tension

- Initial Tension: 3.43N

- Deflection when tension is expected: x=85mm

- Maximum deflection (mm) x=Configurable S Dimension (=75mm)/Standard S Dimension (=50mm)×Standard maximum deflection (=57mm) =75/50×57=85.5 (mm)>85mm

Established based on Deflection when tension is expected ≦Maximum deflection. - Spring Constant k(N/mm)=50 (Reference S Dimension) /Configurable S Dimension (=75mm)×Standard Spring Constant (=0.34N/mm)=50/75×0.34=0.23( N/mm)

- Reaction force F=k(=0.23 N/mm)×x(=85.5mm)+Initial Tension (=3.43N)=0.23×85.5+3.43=23.1N

Other Design Consideration

- The sliding performance of the rack is improved during synchronization by placing oil-free bushings with high O.D. dimension accuracy in the slotted hole area.

Explore Similar Application Examples

Page

1

/

18