(!)Due to Microsoft's end of support for Internet Explorer 11 on 15/06/2022, this site does not support the recommended environment.

Mon. - Fri. 8 a.m. - 6 p.m.

All Categories

Categories

- Automation Components

- Linear Motion

- Rotary Motion

- Connecting Parts

- Rotary Power Transmission

- Motors

- Conveyors & Material Handling

- Locating, Positioning, Jigs & Fixtures

- Inspection

- Sensors, Switches

- Pneumatics, Hydraulics

- Vacuum Components

- Hydraulic Equipment

- Spray Equipment And Accessories

- Pipe, Tubes, Hoses & Fittings

- Modules, Units

- Heaters, Temperature Control

- Aluminum Extrusions, Framing, Support & Posts

- Casters, Leveling Mounts, Posts

- Doors, Cabinet Hardware

- Springs, Shock Absorbers

- Adjustment/Fastening Components, Pins, Magnets

- Antivibration, Soundproofing Materials, Safety Products

- Fasteners

- Materials

- Wiring Components

- LAN Cables / Industrial Network Cables

- Equipment Specific Cables

- Cordsets

- Computer & AV Cables

- Wire/Cable

- Connector (General Purpose)

- Crimp Terminal Components

- Cable Organization

- Cable Gland Components

- Cable Bushing/Clip/Sticker

- Screw/Spacer

- Cable accessories

- Tube

- Electrical Conduits

- Duct/Wiring

- Electrical Wiring Tools

- Dedicated tools

- Soldering supplies

- Electrical & Controls

- Cutting Tools

- Carbide End Mill

- HSS End Mill

- Concrete Drill Bits

- Milling Cutter Insert / Holder

- Core Drill Bits

- Customized Straight Blade End Mill

- Dedicated Cutter

- Crinkey Cutters

- Turning Tool

- Drill

- Cutting Tool Accessories

- Screw Hole Related Tools

- Reamer

- Electric Drill Bits

- Chamfering, Centering Tool

- Hole Saws

- Magnetic Drill Press Cutters

- Step Drills

- Wood Drills & Cutters

- Processing Tools

- packing & logistics storage supplies

- Safety Products

- research and development & cleanroom supplies

- Press Die Components

- Plastic Mold Components

- Ejector Pins

- Sleeves, Center Pins

- Core Pins

- Sprue bushings, Gates, and other components

- Date Mark Inserts, Recycle Mark Inserts, Pins with Gas Vent

- Undercut, Plates

- Leader Components, Components for Ejector Space

- Mold Opening Controllers

- Cooling or Heating Components

- Accessories, Others

- Components of Large Mold, Die Casting

- Injection Molding Components

- Purging Agent

- Injection Molding Machine Products

- Accessories of Equipment

- Auxiliary Equipment

- Air Nippers

- Air Cylinders

- Air Chuck for Runner

- Chuck Board Components

- Frames

- Suction Components

- Parallel Air Chuck

- Special Air Chuck

- Mold Maintenance

- Heating Items

- Heat Insulation Sheets

- Couplers, Plugs, One-touch Joints

- Tubes, Hoses, Peripheral Components

Applications

Brands

- Webcode Seach | Series

-

#CODE

- Discontinued Products

Cutters & Indexable End Mills(Page2)

| Days to Ship |

|

|---|

-

FUJIGEN

[Features]

· Ideal for use in low-rigidity machines such as tapping centers.

· It supports a variety of workpieces with the lineup of negative and positive types.- Volume Discount

Days to Ship: 10 Days or more -

FUJIGEN

Ideal for use in low-rigidity machines such as tapping centers.

[Features]

· Small diameter shank lineup allows use for small machining.

· Unique negative/positive method prevents chatter even with thin objects (can machining, etc.)- Volume Discount

Days to Ship: 11 Days or more -

FUJIGEN

[Features]

· It has undergone innovative evolution. 2 types, a 3-flute type and a 6-flute type, also support high speed cutting.

· Machining diameter can be changed by exchanging the base; machining type can be changed by exchanging the arm.

· Multi-structure supports 3 types: NS (negative S type), PS (positive S type), NT (negative T type)- Volume Discount

Days to Ship: 10 Days or more -

FUJIGEN

[Features]

· It has undergone innovative evolution. 2 types, a 3-flute type and a 6-flute type, also support high speed cutting.

· Machining diameter can be changed by exchanging the base; machining type can be changed by exchanging the arm.

· Multi-structure supports 3 types: NS (negative S type), PS (positive S type), NT (negative T type)- Volume Discount

Days to Ship: 10 Days or more -

FUJIGEN

[Features]

· It has undergone innovative evolution. 2 types, a 3-flute type and a 6-flute type, also support high speed cutting.

· Machining diameter can be changed by exchanging the base; machining type can be changed by exchanging the arm.

· Multi-structure supports 3 types: NS (negative S type), PS (positive S type), NT (negative T type)- Volume Discount

Days to Ship: 10 Days or more -

NEW Nice Cut Arm【1-6 Pieces Per Package】

FUJIGEN

2 types, a 3-flute type and a 6-flute type, also support high speed cutting.

- Volume Discount

Days to Ship: 10 Days or more -

FUJIGEN

With multiple blades, high feed and high-speed cutting are possible.

[Features]

· The tip can be selected from three types of nose radius (R0.2, R0.4, R0.8) and has 4 usable corners to reduce cost.- Volume Discount

Days to Ship: 11 Days or more -

Days to Ship: 10 Days or more -

Days to Ship: 11 Days or more -

FUJIGEN

[Features]

· As it is a negative insert, all 6 corners of the front and back can be used.

· Durability is improved by the double clamp.- Volume Discount

Days to Ship: 10 Days or more -

FUJIGEN

[Features]

· It has undergone innovative evolution. : 2 types, a 3-flute type and a 6-flute type, support high speed cutting.

· Machining diameter can be changed by exchanging the base; machining type can be changed by exchanging the arm.

· Multi-structure supports 3 types: NS (negative S type), PS (positive S type), NT (negative T type).- Volume Discount

Days to Ship: 10 Days or more -

DAISHOWASEIKI

[Features]

· It is comparable to a sharp and tough solid end mill. Throw-away end mill cutter. Low resistance and high efficiency cutter dedicated for lateral feed processing.- Volume Discount

Days to Ship: 12 Days or more -

DAISHOWASEIKI

[Features]

· Dual face contact integrated type provides even higher rigidity. Tip with enhanced rigidity, allowing tough and stable ramping- Volume Discount

Days to Ship: 12 Days or more -

DAISHOWASEIKI

[Features]

· Exhibits amazing cutting performance with No. 40 machining as well as composite machines, and also supports new standard FMH type face mill arbors- Volume Discount

Days to Ship: 12 Days or more -

Full Cut Mill FCM Type Straight Shank Type

DAISHOWASEIKI

[Features]

· A highly versatile straight shank type. Combination with the MEGA Double Power Chuck enables comfortable work.- Volume Discount

Days to Ship: 10 Days or more -

Full Cut Mill FCR Type Straight Shank Type

DAISHOWASEIKI

[Features]

· A highly versatile straight shank type. Combination with the MEGA Double Power Chuck enables comfortable work.- Volume Discount

Days to Ship: 12 Days or more -

ASAHI TOOLS

•Processing Applications : Flat Surface, Groove, Side Surface

•Work Material : Aluminum, Cast Iron, Copper, General Steel, Heat-Treated Steel, Resin, Stainless Steel

•Mounting Method : Arbor

For complete product overview and details on SHE Shell End Mill G2, see the sections below:- Volume Discount

Days to Ship: 8 Days or more -

ASAHI TOOLS

•Processing Applications : Flat Surface, Groove, Side Surface

•Work Material : Aluminum, Cast Iron, Copper, General Steel, Heat-Treated Steel, Resin, Stainless Steel

•Mounting Method : Arbor

For complete product overview and details on Shell End Mill for MCS, MC G2, see the sections below:- Volume Discount

Days to Ship: 8 Days or more -

PSE BORE Phoenix Series Shoulder Milling Cutter Bore Type

OSG

Shoulder cutter. Machining applications: planes, sides, grooves, carving

- Volume Discount

Days to Ship: 8 Days or more -

PFB Phoenix Series Finishing Ball End Mill Carbide Shank

OSG

[Features]

· For finishing.

· It is flat and supports various machined surfaces.- Volume Discount

Days to Ship: 8 Days or more -

Aero Chipper ALX Model Bore Type Milling Cutter

DIJET

[Features]

· It is a tool with excellent abrasion resistance.- Volume Discount

Days to Ship: 9 Days or more -

Side Chipper (Shank Type Mill) SIC Type - Medium Type

DIJET

[Features]

· It is a tool with excellent abrasion resistance.- Volume Discount

Days to Ship: 10 Days or more -

Side Chipper (Bore Type Mill) SIC Type

DIJET

[Features]

· It is a tool with excellent abrasion resistance.- Volume Discount

Days to Ship: 10 Days or more -

Swing Ball SWB Type G-Body Series

DIJET

[Features]

· Tool with excellent wear-resistance- Volume Discount

Days to Ship: 10 Days or more -

Super End Chipper SEC Type - Standard Type, Medium-Long Type

DIJET

Multifunctional tool capable of three-dimensional cutting, including hole drilling and end milling, all performed with a single tool.

- Volume Discount

Days to Ship: 10 Days or more -

Super Die Mate HDM Type Bore Type Mill / Regular Type

DIJET

[Features]

· Supports materials from cast iron and general steel to stainless steel, titanium, and inconel- Volume Discount

Days to Ship: 10 Days or more -

New Back-and-Forth Cutter PFC Type

DIJET

[Features]

· With Coolant Hole[Applications]

· For finishing, reciprocation and vertical wall processing- Volume Discount

Days to Ship: 8 Days or more -

Days to Ship: 9 Days or more -

Mirror Radius End Mill, RNM-S Shape, RNM-T Shape

DIJET

[Features]

· For high precision machining- Volume Discount

Days to Ship: 10 Days or more -

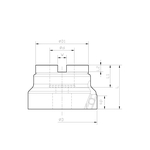

KYOCERA

•Overall Length (L) (mm): 110

•Link Diameter (d) (mm): 32

•Dimension S (mm): 6(5)

•Dimension l (mm): 30

•Wrench: TT-15- Volume Discount

Days to Ship: 11 Days or more -

MSRS15 Type Holder (Inch Specification)

KYOCERA

•Processing Applications : Flat Surface

For complete product overview and details on MSRS15 Type Holder (Inch Specification), see the sections below:- Volume Discount

Days to Ship: 10 Days or more -

MSRS15 Type Holder (mm Specification)

KYOCERA

•Number of Flutes : 4~14

For complete product overview and details on MSRS15 Type Holder (mm Specification), see the sections below:- Volume Discount

Days to Ship: 11 Days or more -

KYOCERA

•Processing Applications : Flat Surface, Groove, Side Surface, Vertical

For complete product overview and details on MEW Type Face Mill, see the sections below:- Volume Discount

Days to Ship: 11 Days or more -

KYOCERA

•Processing Applications : Flat Surface, Groove, Side Surface, Vertical

For complete product overview and details on MEW Type Head, see the sections below:- Volume Discount

Days to Ship: 11 Days or more -

BT Arbor for Modular End Mills (Head Replacement / Two-Face Clamping Spindle Compatible)

KYOCERA

•Dimension L1 (mm): 9

•Coolant Hole: Available- Volume Discount

Days to Ship: 11 Days or more -

MFWN90 Type End Mill (with Coolant Holes at Tip Blade)

KYOCERA

•Overall Length (L) (mm): 110

•Link Diameter (d) (mm): 32

•Dimension S (mm): 8

•Dimension l (mm): 30

•Wrench: TT-15- Volume Discount

Days to Ship: 10 Days or more -

KYOCERA

Processing Application: Side Surface

For complete product overview and details on MEC Type End Mill see the sections below:- Volume Discount

Days to Ship: 8 Days or more -

Days to Ship: 11 Days or more -

KYOCERA

•Dimension S (mm): 6

•Wrench: DTM-6

•Coolant Hole: Available- Volume Discount

Days to Ship: 8 Days or more -

KYOCERA

For complete product overview and details on MECX Type Face Mill, see the sections below:

- Volume Discount

Days to Ship: 11 Days or more -

MEWH Type End Mill (with Coolant Holes at Tip Blade)

KYOCERA

•Seizure Inhibitor: MP-1

•Coolant Hole: Available- Volume Discount

Days to Ship: 11 Days or more -

MECH Type End Mill (with Coolant Holes at Tip Blade)

KYOCERA

•Seizure Inhibitor: MP-1

For complete product overview and details on MECH Type End Mill (with Coolant Holes at Tip Blade) see the sections below:- Volume Discount

Days to Ship: 10 Days or more -

MECH Type Shell Mill (without Coolant Holes)

KYOCERA

•Seizure Inhibitor: MP-1

For complete product overview and details on MECH Type Shell Mill (without Coolant Holes) see the sections below:- Volume Discount

Days to Ship: 10 Days or more -

MECH-BT50 Type (One-Piece Arbor Type, without Coolant Hole)

KYOCERA

•Seizure Inhibitor: MP-1

•Scooping Angle (°) R.R.: -7°- Volume Discount

Days to Ship: 11 Days or more -

MECH-F Type (without Coolant Holes) Front Piece

KYOCERA

•Seizure Inhibitor: MP-1

•Number Of Steps: 2

•Scooping Angle (°) R.R.: -7°- Volume Discount

Days to Ship: 11 Days or more

| Brand |

|---|

| Product Series |

| Days to Ship |

| Processing Applications |

| Flute Diameter D(φ) |

| Work Material |

| Mounting Method |

| Finish Classification |

| Overall Length (L)(mm) |

| Link Diameter (d)(mm) |

| Number of Flutes(sheet) |

| Supported Tip Material Type |

| Max. Cutting Depth (Ad)(mm) |

| Length Under Neck (ℓ1)(mm) |

| Brand | FUJIGEN | FUJIGEN | FUJIGEN | FUJIGEN | FUJIGEN | FUJIGEN | FUJIGEN | FUJIGEN | FUJIGEN | FUJIGEN | FUJIGEN | DAISHOWASEIKI | DAISHOWASEIKI | DAISHOWASEIKI | DAISHOWASEIKI | DAISHOWASEIKI | ASAHI TOOLS | ASAHI TOOLS | OSG | OSG | DIJET | DIJET | DIJET | DIJET | DIJET | DIJET | DIJET | DIJET | DIJET | KYOCERA | KYOCERA | KYOCERA | KYOCERA | KYOCERA | KYOCERA | KYOCERA | KYOCERA | KYOCERA | KYOCERA | KYOCERA | KYOCERA | KYOCERA | KYOCERA | KYOCERA | KYOCERA |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Product Series | Super End Chipper SEC Type - Standard Type, Medium-Long Type | BT Arbor for Modular End Mills (Head Replacement / Two-Face Clamping Spindle Compatible) | |||||||||||||||||||||||||||||||||||||||||||

| Days to Ship | 10 Days or more | 11 Days or more | 10 Days or more | 10 Days or more | 10 Days or more | 10 Days or more | 11 Days or more | 10 Days or more | 11 Days or more | 10 Days or more | 10 Days or more | 12 Days or more | 12 Days or more | 12 Days or more | 10 Days or more | 12 Days or more | 8 Days or more | 8 Days or more | 8 Days or more | 8 Days or more | 9 Days or more | 10 Days or more | 10 Days or more | 10 Days or more | 10 Days or more | 10 Days or more | 8 Days or more | 9 Days or more | 10 Days or more | 11 Days or more | 10 Days or more | 11 Days or more | 11 Days or more | 11 Days or more | 11 Days or more | 10 Days or more | 8 Days or more | 11 Days or more | 8 Days or more | 11 Days or more | 11 Days or more | 10 Days or more | 10 Days or more | 11 Days or more | 11 Days or more |

| Processing Applications | Flat Surface / Side Surface | Flat Surface / Side Surface | Flat Surface / Side Surface | Flat Surface / Side Surface | Flat Surface / Side Surface | Flat Surface / Side Surface | Flat Surface / Side Surface | Flat Surface / Side Surface | Flat Surface / Side Surface | Flat Surface / Side Surface | Flat Surface / Side Surface | Side Surface / Groove | Side Surface / Groove / Thrust (Z-Feed) | Side Surface / Groove | Flat Surface / Side Surface / Groove | Flat Surface / Side Surface / Groove / Thrust (Z-Feed) | Flat Surface / Side Surface / Groove | Flat Surface / Side Surface / Groove | Flat Surface / Side Surface / Groove / Vertical | - | Side Surface / Groove / Vertical | Flat Surface / Side Surface / Groove | Flat Surface / Side Surface / Groove | Side Surface / Groove | Side Surface / Groove / Inclined Cutting / Vertical | Flat Surface / Groove / Vertical | Flat Surface / Side Surface / Chamfer / Vertical | Groove | Flat Surface / Side Surface / Groove / Vertical | Flat Surface / Chamfer | Flat Surface | Flat Surface | Flat Surface / Side Surface / Groove / Vertical | Flat Surface / Side Surface / Groove / Vertical | Side Surface / Groove | Flat Surface / Side Surface / Groove / Vertical | Flat Surface / Side Surface / Groove | Flat Surface / Side Surface / Groove | Flat Surface / Side Surface / Groove | Flat Surface / Side Surface / Groove | Flat Surface / Side Surface / Groove | Flat Surface / Side Surface / Groove | Flat Surface / Side Surface | - | - |

| Flute Diameter D(φ) | 30 ~ 40 | 60 ~ 80 | 100 ~ 150 | 100 ~ 130 | 110 ~ 160 | - | 20 ~ 50 | 30 ~ 80 | 40 | 40 ~ 80 | 100 ~ 150 | 16 ~ 32 | 16 ~ 32 | 50 ~ 80 | 12 ~ 50 | 17 ~ 33 | 50 ~ 100 | 50 ~ 100 | - | 8 ~ 30 | 50 ~ 63 | 20 ~ 50 | 63 ~ 100 | 40 ~ 50 | 16 ~ 40 | 50 ~ 80 | 50 | 8 ~ 30 | 16 ~ 32 | - | - | - | - | - | - | 50 ~ 80 | 10 ~ 50 | 16 ~ 32 | 8 ~ 33 | - | 25 ~ 50 | 25 ~ 50 | - | 50 ~ 100 | - |

| Work Material | Stainless Steel / Aluminum / Resin | General Steel / Stainless Steel / Aluminum / Resin | General Steel / Stainless Steel / Aluminum / Resin | Stainless Steel / Aluminum / Resin | General Steel / Stainless Steel / Aluminum / Resin | General Steel / Stainless Steel / Aluminum / Resin | General Steel / Stainless Steel / Aluminum / Resin | General Steel / Stainless Steel / Aluminum / Resin | General Steel / Stainless Steel / Aluminum / Resin | General Steel / Stainless Steel / Aluminum / Resin | General Steel / Stainless Steel / Aluminum / Resin | - | - | - | - | - | General Steel / Heat-Treated Steel / Stainless Steel / Cast Iron / Aluminum / Copper / Resin | General Steel / Heat-Treated Steel / Stainless Steel / Cast Iron / Aluminum / Copper / Resin | - | - | General Steel / Heat-Treated Steel / High-Hardness Steel / Stainless Steel / Cast Iron / Titanium / Copper | General Steel / Heat-Treated Steel / High-Hardness Steel / Stainless Steel / Cast Iron / Titanium / Copper | General Steel / Heat-Treated Steel / High-Hardness Steel / Stainless Steel / Cast Iron / Titanium / Copper | - | General Steel / Heat-Treated Steel / High-Hardness Steel / Stainless Steel / Cast Iron / Titanium / Copper | General Steel / Heat-Treated Steel / High-Hardness Steel / Stainless Steel / Cast Iron / Titanium / Copper | General Steel / Cast Iron | General Steel / Heat-Treated Steel / High-Hardness Steel / Stainless Steel / Cast Iron | General Steel / Heat-Treated Steel / High-Hardness Steel / Stainless Steel / Cast Iron | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - |

| Mounting Method | Handle Model | Handle Model | Handle Model | Handle Model | Handle Model | Handle Model | Handle Model | Handle Model | Handle Model | Handle Model | Handle Model | Handle Model | Handle Model | Arbor | Handle Model | Handle Model | Arbor | Arbor | - | Handle Model | Arbor | Handle Model | Arbor | Handle Model | Handle Model | Arbor | Arbor | Handle Model | Handle Model | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - |

| Finish Classification | Finish Processing | Finish Processing | Finish Processing | Finish Processing | Finish Processing | Finish Processing | Finish Processing | Finish Processing | Finish Processing | Finish Processing | Finish Processing | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | Finish Processing | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - |

| Overall Length (L)(mm) | 85 | 120 | 120 ~ 123.5 | 123.5 | 120 ~ 123.5 | - | 100 ~ 105 | 105 ~ 200 | 134.6 ~ 185 | 120 | 120 ~ 123.5 | - | - | 40 ~ 50 | 90 ~ 180 | 120 ~ 180 | - | 60 ~ 110 | - | 100 ~ 290 | - | 110 ~ 150 | - | 200 ~ 250 | 130 ~ 160 | - | - | 83 ~ 240 | 140 ~ 300 | 110 | - | - | - | 43 ~ 63 | - | 110 | 80 ~ 250 | 43 ~ 63 | 80 ~ 130 | - | 120 ~ 160 | 120 ~ 185 | - | 143 ~ 173 | - |

| Link Diameter (d)(mm) | - | - | - | - | - | - | - | - | - | - | - | - | - | - | 16 ~ 32 | 16 ~ 32 | - | - | - | 8 ~ 32 | - | 20 ~ 32 | - | 50.8 | 16 ~ 32 | - | 22 | 12 ~ 32 | 16 ~ 32 | 32 | - | - | - | - | - | 32 | 10 ~ 32 | - | 10 ~ 32 | - | 25 ~ 42 | 25 ~ 42 | - | - | - |

| Number of Flutes(sheet) | 3 | 3 | 3 ~ 6 | 3 ~ 6 | 3 ~ 6 | 3 ~ 6 | 2 ~ 5 | 2 ~ 4 | 2 | 3 | 3 ~ 6 | 2 | 2 | 5 ~ 6 | 1 ~ 5 | 2 ~ 3 | 6 ~ 10 | 6 ~ 10 | 3 ~ 11 | 2 | 4 ~ 5 | - | - | - | - | 3 ~ 4 | 4 | - | - | 3 ~ 5 | 4 ~ 14 | 4 ~ 14 | 4 ~ 6 | 2 ~ 4 | - | 3 ~ 5 | 1 ~ 5 | 2 ~ 4 | 1 ~ 7 | 8 ~ 10 | 6 ~ 15 | 8 ~ 42 | 8 ~ 30 | 28 ~ 42 | 8 ~ 12 |

| Supported Tip Material Type | Carbide Coating / No Carbide Coating | Carbide Coating / No Carbide Coating / Cermet / Diamond (PCD) | Carbide Coating / No Carbide Coating / Cermet / Diamond (PCD) | Carbide Coating / No Carbide Coating | Carbide Coating / No Carbide Coating / Cermet | Carbide Coating / No Carbide Coating / Cermet / Diamond (PCD) | Carbide Coating / No Carbide Coating / Cermet | No Carbide Coating | Carbide Coating / No Carbide Coating | Carbide Coating / No Carbide Coating / Cermet | Carbide Coating / No Carbide Coating / Cermet / Diamond (PCD) | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | Carbide Coating | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - |

| Max. Cutting Depth (Ad)(mm) | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - |

| Length Under Neck (ℓ1)(mm) | - | - | - | - | - | - | - | - | - | - | - | 45 ~ 90 | 45 ~ 90 | 20 ~ 22 | 15 ~ 48 | 25 ~ 48 | - | - | - | 20 ~ 165 | - | 25 ~ 40 | - | 100 ~ 150 | 50 ~ 70 | - | - | 18.5 ~ 49 | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - |

Loading...

Configure

Specification/Dimensions

-

Processing Applications

-

Metric / Inch

-

Flute Diameter D(φ)

- 6

- 8

- 10

- 12

- 13.2

- 13.4

- 14

- 15

- 15.4

- 16

- 16.2

- 17

- 18

- 18.2

- 18.4

- 18.9

- 19

- 20

- 20mm

- 20.2

- 21

- 22

- 23.2

- 23.4

- 23.8

- 24

- 25

- 25mm

- 26

- 28

- 28.2

- 30

- 30.7

- 32

- 32mm

- 33

- 33.4

- 34

- 35

- 35.9

- 38

- 38.2

- 39

- 40

- 40mm

- 42

- 43

- 44

- 45

- 46.4

- 47

- 48.7

- 50

- 50mm

- 51

- 51.2

- 52

- 55

- 60

- 61.7

- 63

- 63.4

- 63.5

- 64

- 65

- 66

- 68

- 70

- 75

- 76.2

- 78.7

- 80

- 80mm

- 83.4

- 84

- 88

- 90

- 98.7

- 100

- 100mm

- 101.6

- 105

- 110

- 123.7

- 125

- 125mm

- 127

- 130

- 140

- 150

- 152.4

- 160

- 160mm

- 200

-

Work Material

-

Mounting Method

-

Finish Classification

-

Overall Length (L)(mm)

-

26~27

- 26

- 27

-

32~38

- 32

- 33

- 35

- 38

-

40~49

- 40

- 40$40.7

- 43

- 45

- 49

-

50~57

- 50

- 50$50.7

- 57

-

60~68

- 60

- 63

- 63$63.7

- 68

-

70~77.7

- 70

- 73

- 74

- 76

- 77.7

-

80~88

- 80

- 81

- 83

- 84

- 84.7

- 85

- 88

-

90~98.7

- 90

- 92

- 95

- 98

- 98.7

-

100~109

- 100

- 102

- 103

- 104

- 105

- 108

- 109

-

110~117

- 110

- 112

- 115

- 117

-

120~128

- 120

- 121

- 123

- 123.5

- 124

- 125

- 128

-

130~138

- 130

- 132

- 133

- 134

- 134.6

- 135

- 136

- 138

-

140~145

- 140

- 141

- 143

- 144

- 145

-

150~158

- 150

- 155

- 158

-

160~166

- 160

- 165

- 166

-

170~176

- 170

- 172

- 173

- 175

- 176

-

180~186

- 180

- 184.6

- 185

- 186

-

190~191

- 190

- 191

-

200

-

210~215

- 210

- 215

-

220

-

230

-

240

-

250~256

- 250

- 256

-

260

-

270

-

290

-

300~306

- 300

- 306

-

350

-

-

Link Diameter (d)(mm)

-

Number of Flutes(sheet)

-

Supported Tip Material Type

-

Max. Cutting Depth (Ad)(mm)

-

Length Under Neck (ℓ1)(mm)

Narrow search by specifying Manufacturer

CAD

-

- 2D

- 3D

How can we improve?

How can we improve?

While we are not able to respond directly to comments submitted in this form, the information will be reviewed for future improvement.

Customer Privacy Policy

Thank you for your cooperation.

While we are not able to respond directly to comments submitted in this form, the information will be reviewed for future improvement.

Please use the inquiry form.

Customer Privacy Policy