(!)Due to Microsoft's end of support for Internet Explorer 11 on 15/06/2022, this site does not support the recommended environment.

Mon. - Fri. 8 a.m. - 6 p.m.

All Categories

Categories

- Automation Components

- Linear Motion

- Rotary Motion

- Connecting Parts

- Rotary Power Transmission

- Motors

- Conveyors & Material Handling

- Locating, Positioning, Jigs & Fixtures

- Inspection

- Sensors, Switches

- Pneumatics, Hydraulics

- Vacuum Components

- Hydraulic Equipment

- Spray Equipment And Accessories

- Pipe, Tubes, Hoses & Fittings

- Modules, Units

- Heaters, Temperature Control

- Aluminum Extrusions, Framing, Support & Posts

- Casters, Leveling Mounts, Posts

- Doors, Cabinet Hardware

- Springs, Shock Absorbers

- Adjustment/Fastening Components, Pins, Magnets

- Antivibration, Soundproofing Materials, Safety Products

- Fasteners

- Materials

- Wiring Components

- LAN Cables / Industrial Network Cables

- Equipment Specific Cables

- Cordsets

- Computer & AV Cables

- Wire/Cable

- Connector (General Purpose)

- Crimp Terminal Components

- Cable Organization

- Cable Gland Components

- Cable Bushing/Clip/Sticker

- Screw/Spacer

- Cable accessories

- Tube

- Electrical Conduits

- Duct/Wiring

- Electrical Wiring Tools

- Dedicated tools

- Soldering supplies

- Electrical & Controls

- Cutting Tools

- Carbide End Mill

- HSS End Mill

- Concrete Drill Bits

- Milling Cutter Insert / Holder

- Core Drill Bits

- Customized Straight Blade End Mill

- Dedicated Cutter

- Crinkey Cutters

- Turning Tool

- Drill

- Cutting Tool Accessories

- Screw Hole Related Tools

- Reamer

- Electric Drill Bits

- Chamfering, Centering Tool

- Hole Saws

- Magnetic Drill Press Cutters

- Step Drills

- Wood Drills & Cutters

- Processing Tools

- packing & logistics storage supplies

- Safety Products

- research and development & cleanroom supplies

- Press Die Components

- Plastic Mold Components

- Ejector Pins

- Sleeves, Center Pins

- Core Pins

- Sprue bushings, Gates, and other components

- Date Mark Inserts, Recycle Mark Inserts, Pins with Gas Vent

- Undercut, Plates

- Leader Components, Components for Ejector Space

- Mold Opening Controllers

- Cooling or Heating Components

- Accessories, Others

- Components of Large Mold, Die Casting

- Injection Molding Components

- Purging Agent

- Injection Molding Machine Products

- Accessories of Equipment

- Auxiliary Equipment

- Air Nippers

- Air Cylinders

- Air Chuck for Runner

- Chuck Board Components

- Frames

- Suction Components

- Parallel Air Chuck

- Special Air Chuck

- Mold Maintenance

- Heating Items

- Heat Insulation Sheets

- Couplers, Plugs, One-touch Joints

- Tubes, Hoses, Peripheral Components

Applications

Brands

- Webcode Seach | Series

-

#CODE

- Discontinued Products

Tubes & Tube Accessories

| Days to Ship |

|

|---|

-

Polyurethane Tubing TU/TIUB Series

SMC

Flexible polyurethane tubing.

[Features]

· Flexible.

· Polyurethane tubing.

· Additional 21 new colors.

[Applications]

· For general pneumatic tubing.- Volume Discount

Days to Ship: Same day or more Show Stock Products

-

Fluoropolymer Tubing (FEP) TH/TIH Series

SMC

A fluoropolymer tubing with superior durability in chemical environments.

[Features]

· Compatible with Japan's Food Sanitation Law.

· Operating temperature: 200°C (varies depending on the conditions).

· Maximum operating pressure 2.3 MPa or less (at 20°C) (varies by size).

· Complies with the FDA (Food and Drug Administration) §177-1550 dissolution test.- Volume Discount

Days to Ship: Same day or more Show Stock Products

-

Soft Nylon Tubing TS/TISA Series

SMC

Pliable soft nylon tubing.

[Features]

· Maximum operating pressure 1.0 MPa or less (at 20°C).

[Applications]

· For general pneumatic tubing.- Volume Discount

Days to Ship: Same day or more Show Stock Products

-

Tubing - EPDM, Weather-Resistant

USA Industrials

EPDM is a strong material with a broad temperature range. It has excellent resistance to water, steam, and many chemicals.

Days to Ship: Quote -

Tubing - Nylon, Multipurpose, N2 Series

Nitta

This nylon tube N2 features excellent oil resistance, chemical resistance, and abrasion resistance. The group 2 type can be used at a maximum of 4.8 Mpa (at 20°C).

[Features]

· Product features superior oil resistance and chemical resistance properties.

· The group 2 type can be used at a maximum of 4

· .8 Mpa (at 20°C).

· Product features superior abrasion resistance- Volume Discount

Days to Ship: 8 Days or more -

Flame Retardant (Equivalent To UL-94 Standard V-0) FR Soft Nylon Tubing TRS Series

SMC

Flame-retardant tubing.

[Features]

· Maximum operating pressure 1.2 MPa or less (at 20°C)

· For use in environments where spatter may occur / Flame retardant (equivalent to UL-94 standard V-0)

[Applications]

· Suitable for air and water piping in environments with sparks from spot welders, etc.- Volume Discount

Days to Ship: 3 Days or more -

MISUMI

Tubes excellent in oil resistance

- Lead Time Reduction

- inCAD Components

Days to Ship: 8 Days or more -

Tubing - Nylon, Soft, Straight, General Use, NB Series

Nihon Pisco

A tube that can be used in hot water and thermal oil.

- Volume Discount

Days to Ship: Same day or more Show Stock Products

-

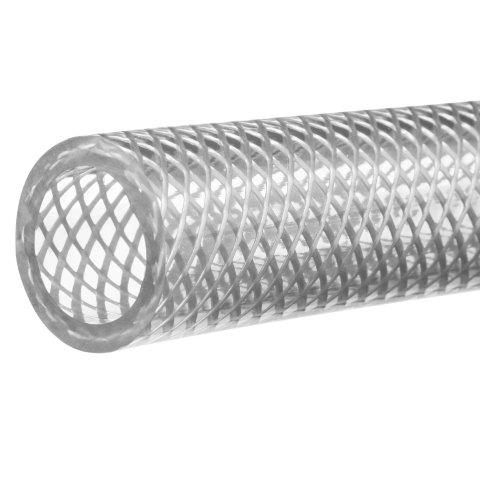

Tubing - PVC, Multipurpose, FDA Compliant, Polyester Braid Reinforced

USA Industrials

This PVC is reinforced with a polyester braid to withstand higher pressures. PVC is used for general purposes and can withstand a wide range of chemicals

Days to Ship: Quote -

Tubing - Fluoropolymer, Nylon Outer Layer, Flexible, Double Layer, Abrasion Resistant, TES Series

Nitta

Two-layer structure consisting of inside layer (special fluororesin) + outer layer (special nylon resin). Excellent in flexibility and suitable for movable piping such as robots. Semi-transparent, so fluids can be visually checked.

- Volume Discount

Days to Ship: 8 Days or more -

Tubing - Polyurethane, for Air, U2 Series

Nitta

Urethane Tube - The U2 delivers a good balance between flexibility and pressure resistance. The excellent construction makes it suitable for general air pressure piping.

- Volume Discount

Days to Ship: 8 Days or more -

Polyurethane Coil Tubing TCU Series【1-5 Pieces Per Package】

SMC

Flexible tubing that can be used for compact piping.

[Features]

· Flexible.

· Makes compact piping possible.

· Fluid: air.

· Maximum operating pressure: 0.8 MPa or less (at 20°C).

[Applications]

· For piping in movable parts.- Volume Discount

Days to Ship: Same day or more Show Stock Products

-

Fluoropolymer Tubing TL/TIL Series

SMC

Fluoropolymer tubing with a highly smooth internal surface.

[Features]

· Maximum operating pressure 1.0 MPa or less (at 20°C).

· Maximum operating temperature: 260°C (varies depending on the conditions).

[Applications]

· Suitable for applications requiring a small amount of elution of fluorine ions.- Volume Discount

Days to Ship: Quote -

Tubing - PVC, Multipurpose, FDA Compliant

USA Industrials

PVC is used for general purposes and can withstand a wide range of chemicals

Days to Ship: Quote -

Tubing - Polyurethane, Water-Resistant

MISUMI

Highly Water-resistant Tubes

For complete product overview and details on Tubing - Polyurethane, Water-Resistant see the sections below:- Volume Discount

- inCAD Components

Days to Ship: Same day or more Show Stock Products

-

Tubing - Weld-Spatter-Resistant

MISUMI

Tubes flexible and easy to handle

- Lead Time Reduction

- inCAD Components

Days to Ship: 8 Days or more -

Tubing Accessories - Tube Clips

MISUMI

•Type: (Related Components) Tube Cutters

•Color: Brown- Volume Discount

- inCAD Components

Days to Ship: 8 Days or more -

Tubing Accessories - Soft Tube Inserts【1-10 Pieces Per Package】

MISUMI

[Features] Prevents shrinkage of tube from inside.

- Volume Discount

- inCAD Components

Days to Ship: 8 Days or more -

Tubing Accessories - Tube Cutter

MISUMI

This is Cutter for tubes.

For complete product overview and details on Tubing Accessories - Tube Cutter see the sections below:- Volume Discount

Days to Ship: Same day Show Stock Products

-

Tubing - Polyurethane, UB Series

Nihon Pisco

Urethane tube with superior flexibility.

[Features]

· Excellent flexibility.

· Ideal for general pressure pipes that need a small bend radius.

· Many tube colors.

· A cut mark is displayed at intervals of 500mm, which is useful when cutting the tube.

· We also manufacture long length tubes by custom order.- Volume Discount

Days to Ship: Same day or more Show Stock Products

-

Tubing - Polyurethane, Touch Tube, TP Series

Chiyoda

Polyurethane tube with superior flexibility that achieves small bending radius.

[Features]

· Soft and difficult to break: superior flexibility, very small bending radius.

· Excellent oil resistance: Suitable for air piping in a plant.

· Excellent wear resistance: superior mechanical strength and wear resistance, optimal for equipment piping and robot piping, superior outer diameter accuracy.

· Cut marks and model view: cut marks printed at 1 m intervals; optimal for cutting work and inventory control- Volume Discount

Days to Ship: 8 Days or more -

Tubing - Polyurethane, Coil, for Air, TPS Series

Chiyoda

The resilient spiral tube is oil resistant.

[Features]

· With the TE tube specification, there is a perfect balance between flexibility and resilience.

· Wide range of variations in tube size and usable range.

· Fitting changes (coupling type, screw size changes, etc.), usable range, lengthening/shortening of the straight section, color changes (see TE tube B-1) can be carried out from one unit.

· Optimal for air piping within a factory environment and has excellent oil resistance.

· Compared to TPS, the tube boasts excellent strength characteristics.- Volume Discount

Days to Ship: 8 Days or more -

Flame Retardant (Equivalent To UL-94 Standard V-0) FR Double Layer Polyurethane Tubing TRBU Series

SMC

Double-layer polyurethane tubing.

[Features]

· Maximum operating pressure 0.8 MPa or less (at 20°C).

· For use in areas where spatter occurs. Flame retardant (equivalent to UL-94 standard V-0).

· Superior resiliency even when compared to nylon tubing.- Volume Discount

Days to Ship: 3 Days or more -

Multi-Tube Holder TM Series【10 Pieces Per Package】

SMC

A multi-tube holder to facilitate arrangement of tubing.

[Features]

· Easy tube insertion and firm securing.

· Possible to separate options depending on number of connected tubes.

· Use of flame-retardant resin (equivalent to UL-94 standard V-0).- Volume Discount

Days to Ship: Same day or more Show Stock Products

-

Tubing - PVC, Multipurpose, for Fuels and Lubricants

USA Industrials

This PVC tubing is specifically designed for conveying fuels and lubricants and is tinted yellow for color identification. It is also softer and more flexible than other PVC tubing.

Days to Ship: Quote -

Tubing - Silicone, High Temperature, Metal Detectable, FDA

USA Industrials

Metal fillers allow this food grade tubing to be picked up by metal detection systems should they tear or fall into the process stream. Silicone has an excellent temperature range and good resistance to mild chemicals, animal and vegetable oils, and water.

Days to Ship: Quote -

Tubing - Silicone, High Temperature, Medical Grade

USA Industrials

This high purity silicone tubing is platinum cured, made of FDA compliant materials, and certified to USP Class VI standards. It is frequently used in medical and biopharmaceutical applications that have strict requirements on purity and low extractables.

Days to Ship: Quote -

MISUMI

Nylon Tubes excellent in flexibility

- Volume Discount

- Lead Time Reduction

- inCAD Components

Days to Ship: 8 Days or more -

Tubing - Nylon, Pressure-Resistant

MISUMI

Available for oil supplying or oil hydraulic plumbing.

- Volume Discount

- Lead Time Reduction

- inCAD Components

Days to Ship: 8 Days or more -

Tubing - Polyurethane, Touch Coil, TPS Series

Chiyoda

A spiral tube with superior flexibility.

[Features]

· A feature of the TE tube is that inherited one touch fittings can be used as-is.

· Special orders are possible.- Volume Discount

Days to Ship: 8 Days or more -

Tubing - Polyurethane, Multi-Coil, 2-MPS/3-MPS Series

Chiyoda

Colorful spiral tube with excellent flexibility.

[Features]

· Directly inherited the features of the TP tube.

· One-touch fittings can be used.

· Can be made to order- Volume Discount

Days to Ship: 8 Days or more -

Tubing - Polyurethane, Chloroprene Outer Layer, Weld-Spatter-Resistant, CTP Series

Chiyoda

Sputter prevention tube which uses chloroprene rubber on the outer skin.

[Features]

· For air only; directly inherits the features of TP inner.

· Wide range of color variation, which is convenient for pipe management.

· Two-layer tube with chloroprene rubber used for the outer skin- Volume Discount

Days to Ship: 8 Days or more -

Tubing - Polyurethane, Tight Coil, Female BSPP Fittings

Muromoto

Tightly wound diameter at φ28mm. Offers a wide range of uses, including air-driven equipment. Internal diameter of tube 5, external diameter 8.

- Volume Discount

Days to Ship: 8 Days or more -

Tubing - Flame-Retardant Polymer, for Spot Welding, FS Series

Nitta

Flame retardant tube FS has excellent self-extinguishing capabilities corresponding to UL94 Standard V-0. Excellent flexibility due to single layer structure. Marking is added to total length for indicating insert length.

- Volume Discount

Days to Ship: 10 Days or more -

Junkosha

By using a double tube with overlapped special resins that are flame resistant, sparks can be prevented. High flexibility, with excellent weather and water resistance.

[Features]

▪ Standard colors: black, red, blue, green, white, yellow, light beige, light red, light green (yellow, light beige, light red, light green with a 100-m roll only).

▪ The equipment can be implemented as a piping tube of spot welded equipment where noncombustible resin (exact UL94V-0) is used in the outer layer.

▪ By using the exclusively applied stripper (that comes with tube cutter), it is possible to insert the equipment into the Junlon one-touch fitting W series and it is also possible to detach the speedy outer layer that complies with the infixing.

▪ Moreover, the pitch of the infixing in the outer layer is displayed and the length of its detachment is easily visible.- Volume Discount

Days to Ship: 8 Days or more -

Tubing - Nylon, Soft, Junron A, AS1 Series, Metric

Junkosha

[Features]

· Excellent mechanical strengths (especially, pressure resistance, wear resistance and bending fatigue tolerance).

· Product has superior low temperature and heat resistance properties.

· Highly flexible.

· Product has superior oil resistance and chemical resistance properties (especially alkali resistance).

▪ No risk of toxic substances being released.

▪ It is light in weight and has excellent workability- Volume Discount

Days to Ship: 8 Days or more -

Tubing - Polyurethane, for Barb Fitting, Junron UF, 25 Series

Junkosha

Mechanical strength, in particular wear resistance is excellent.

[Features]

· Excellent mechanical strengths (especially, pressure resistance and wear resistance).

· Product has superior low temperature and heat resistance properties.

· Temperature range of resin for continuous operation without load: -40°C ~ +80°C.

· Flexible and high impact resilience rate.

· No risk of poisonous substances being released.

· Minimum bending radius. Excellent workability.

· *If you need water resistance, use Junlon UF.- Volume Discount

Days to Ship: 8 Days or more -

Fluoropolymer Tubing (PFA) Metric Size, TLM Series

SMC

Superior heat resistance: fluoropolymer tubing (PFA) metric size, TLM series.

[Features]

· Uses highly chemical-resistant fluoropolymer.

[Applications]

· Used in the manufacture of solar cells, liquid crystals, hard disk drives, and in the healthcare and food industries.- Volume Discount

Days to Ship: Same day or more Show Stock Products

-

Flame-Resistant (Equivalent To UL-94 Standard V-0) FR Three-Layer Polyurethane Tubing, TRTU Series

SMC

Triple-layered, flame-resistant (equivalent to UL-94 standard V-0) polyurethane tubing, TRTU series.

[Features]

· Includes an aluminum layer between the outer sheath and the inner tube for improved spatter resistance.

[Applications]

· Suitable for air and water piping in environments with sparks from arc welders, etc.- Volume Discount

Days to Ship: 3 Days or more -

SMC

Nylon tubing for general pneumatic tubing.

[Features]

· Maximum operating pressure 3.0 MPa or less (T0604, at 20°C).

[Applications]

· Fluid: air, water.- Volume Discount

Days to Ship: Same day or more Show Stock Products

-

Soft Fluoropolymer Tubing TD/TID Series

SMC

Compatible with Japan's Food Sanitation Law.

[Features]

· Flexibility: Improved by approx. 20%.

· Operating temperature: Max. 260°C.

[Applications]

· Suitable for applications which require flexibility.- Volume Discount

Days to Ship: Same day or more Show Stock Products

-

Tubing - Silicone, High Temperature, FDA Compliant

USA Industrials

This Silicone is highly flexible and meets FDA standards for use with water, food, and beverage. It is often used in food processing, air and water transfer, and breweries and distilleries.

Days to Ship: Quote -

Tubing - Viton, Aramid Braid Reinforced, Chemical-Resistant

USA Industrials

Viton tubing withstands a wide variety of chemicals, oils, and fuels. It is also reinforced with an aramid braid to withstand higher pressures.

Days to Ship: Quote -

Tubing - PVC, Multipurpose, 3-A Sanitary Standards Compliant, Steel Wire Reinforced

USA Industrials

This high purity PVC tubing is made of FDA compliant materials and certified to 3A standards for food, beverage, dairy, and pharmaceutical applications. It is also reinforced with steel wire to withstand higher pressures and reduce the buildup of static electricity. PVC is used for general purposes and can withstand a wide range of chemicals.

Days to Ship: Quote -

Tubing - Silicone, High Temperature, 3-A Sanitary Standards Compliant

USA Industrials

This high purity silicone tubing is platinum cured, made of FDA compliant materials, and certified to 3A standards for food, beverage, dairy, and pharmaceutical applications.

Days to Ship: Quote

| Brand |

|---|

| Product Series |

| CAD |

| Days to Ship |

| Specifications |

| Type |

| Material |

| Cutting Service Usage |

| Color |

| O.D. [Distinction] |

| Applicable Fluid |

| O.D. D(Ø) |

| I.D. [Distinction] |

| I.D. d(Ø) |

| Number of Bores(per piece) |

| Material, Urethane |

| Material: Nylon |

| Material, Fluororesin |

| Operating Environment |

| O.D. (2nd Core) |

| O.D. (3rd Core) |

| O.D. (4th Core) |

| I.D. (2nd Core) |

| I.D. (3rd Core) |

| I.D. (4th Core) |

| Types of Related components |

|

|

|

| ||||||||||||||||||||||||||||||||||||||||||

| Brand | SMC | SMC | SMC | USA Industrials | Nitta | SMC | MISUMI | Nihon Pisco | USA Industrials | Nitta | Nitta | SMC | SMC | USA Industrials | MISUMI | MISUMI | MISUMI | MISUMI | MISUMI | Nihon Pisco | Chiyoda | Chiyoda | SMC | SMC | USA Industrials | USA Industrials | USA Industrials | MISUMI | MISUMI | Chiyoda | Chiyoda | Chiyoda | Muromoto | Nitta | Junkosha | Junkosha | Junkosha | SMC | SMC | SMC | SMC | USA Industrials | USA Industrials | USA Industrials | USA Industrials |

| Product Series | Flame Retardant (Equivalent To UL-94 Standard V-0) FR Soft Nylon Tubing TRS Series | Tubing - PVC, Multipurpose, FDA Compliant, Polyester Braid Reinforced | Tubing - Fluoropolymer, Nylon Outer Layer, Flexible, Double Layer, Abrasion Resistant, TES Series | Tubing Accessories - Soft Tube Inserts【1-10 Pieces Per Package】 | Flame Retardant (Equivalent To UL-94 Standard V-0) FR Double Layer Polyurethane Tubing TRBU Series | Tubing - Polyurethane, Chloroprene Outer Layer, Weld-Spatter-Resistant, CTP Series | Tubing - Flame-Retardant Polymer, for Spot Welding, FS Series | Tubing - Polyurethane, for Barb Fitting, Junron UF, 25 Series | Flame-Resistant (Equivalent To UL-94 Standard V-0) FR Three-Layer Polyurethane Tubing, TRTU Series | Tubing - PVC, Multipurpose, 3-A Sanitary Standards Compliant, Steel Wire Reinforced | Tubing - Silicone, High Temperature, 3-A Sanitary Standards Compliant | ||||||||||||||||||||||||||||||||||

| CAD |

|

|

|

|

|

|

|

|

| ||||||||||||||||||||||||||||||||||||

| Days to Ship |

Same day or more

Show Stock Products |

Same day or more

Show Stock Products |

Same day or more

Show Stock Products | Quote | 8 Days or more | 3 Days or more | 8 Days or more |

Same day or more

Show Stock Products | Quote | 8 Days or more | 8 Days or more |

Same day or more

Show Stock Products | Quote | Quote |

Same day or more

Show Stock Products | 8 Days or more | 8 Days or more | 8 Days or more |

Same day

Show Stock Products |

Same day or more

Show Stock Products | 8 Days or more | 8 Days or more | 3 Days or more |

Same day or more

Show Stock Products | Quote | Quote | Quote | 8 Days or more | 8 Days or more | 8 Days or more | 8 Days or more | 8 Days or more | 8 Days or more | 10 Days or more | 8 Days or more | 8 Days or more | 8 Days or more |

Same day or more

Show Stock Products | 3 Days or more |

Same day or more

Show Stock Products |

Same day or more

Show Stock Products | Quote | Quote | Quote | Quote |

| Specifications |

|

|

|

|

|

|

| ||||||||||||||||||||||||||||||||||||||

| Type | Straight | Straight | Straight | - | Straight | Straight | Straight | Straight | - | Straight | Straight | Coil | Straight | - | Straight | Straight | (Related Components) Tube Cutters | (Related Components) Tube Cutters / Related Components | (Related Components) Tube Cutters | Straight | Straight | Coil | Straight | Related Components | - | - | - | Straight | Straight | Coil | Coil | Straight | Coil | Straight | Straight | Straight | Straight | Straight | Straight | Straight | Straight | - | - | - | - |

| Material | Urethane | Fluororesin | Nylon | Others | Nylon | Nylon | Nylon | Nylon | PVC | Fluororesin | Urethane | Urethane | Fluororesin | PVC | Urethane | Urethane | Others | Others | Others | Urethane | Urethane | Urethane | - | - | PVC | Silicon Rubber | Silicon Rubber | Nylon | Nylon | Urethane | Urethane | Others | Urethane | Others | - | Nylon | Urethane | Fluororesin | Urethane | Nylon | Fluororesin | Silicon Rubber | Fluororesin | PVC | Silicon Rubber |

| Cutting Service Usage | No | No | No | - | - | No | - | - | - | - | - | No | No | - | - | - | - | - | - | - | - | - | No | - | - | - | - | - | - | - | - | - | - | - | - | - | - | No | No | No | No | - | - | - | - |

| Color | White / Transparent (including non-white colors) / Red / Blue / Yellow / Green / Orange / Gray / Pink / Brown / Purple / Silver | Transparent (including non-white colors) / Red | Transparent (including non-white colors) / Blue / Yellow / Green | Black | Black / Translucent White / Red / Blue / Yellow / Green | Transparent (including non-white colors) / Blue / Green | Black / White | Black / Translucent White / Transparent (including non-white colors) / Red / Blue / Yellow | Transparent (including non-white colors) | Transparent (including non-white colors) | Black / White / Transparent (including non-white colors) / Red / Blue / Yellow / Green | White / Transparent (including non-white colors) / Red / Blue / Yellow / Green / Gray | Transparent (including non-white colors) | Transparent (including non-white colors) | Black / Transparent Blue | Black / Red / Green | Brown | Brown | Brown | Black / Translucent White / Transparent (including non-white colors) / Red / Blue / Yellow / Green / Orange / Ocher | Black / White / Transparent (including non-white colors) / Red / Blue / Yellow / Green | Yellow | - | - | Yellow | Blue | Transparent (including non-white colors) | Black / White | Black / White | Black | Multi Color | Black / White / Red / Blue / Green | Green | Black / White / Red / Blue / Yellow / Green | Black / White / Red / Blue / Yellow / Green / Others | Black / Translucent White / Red / Blue / Yellow / Green | Blue | Transparent (including non-white colors) / Red | White / Transparent (including non-white colors) / Red / Blue / Yellow / Green | Transparent (including non-white colors) / Blue / Yellow / Green | Transparent (including non-white colors) | Transparent (including non-white colors) / Red / Transparent Blue | Black | Transparent (including non-white colors) | Translucent White |

| O.D. [Distinction] | ~2 ~ ~20 | ~4 ~ ~20 | ~4 ~ ~20 | - | ~4 ~ ~20 | ~6 ~ ~15 | - | ~4 ~ ~20 | - | ~4 ~ ~10 | ~3 ~ ~20 | ~4 ~ ~15 | ~4 ~ ~30 | - | - | - | - | - | - | ~2 ~ ~20 | ~4 ~ ~15 | ~8 ~ ~20 | - | - | - | - | - | - | - | ~4 ~ ~15 | ~4 ~ ~15 | ~8 ~ ~15 | ~8 | ~6 ~ ~15 | ~6 ~ ~15 | ~4 ~ ~20 | ~4 ~ ~6 | ~2 ~ ~20 | ~6 ~ ~15 | ~4 ~ ~20 | ~4 ~ ~15 | - | - | - | - |

| Applicable Fluid | Water / Air | Water / Air | Water / Air | Water / Chemical | Water / Air / General Hydraulic Oil | Water / Air | Water / Air / General Hydraulic Oil | Water / Air / Thermal Media Oil | Water / Air / Chemical / General Hydraulic Oil / Thermal Media Oil | Water / Air | Water / Air | Air | Water / Chemical | Water / Air / Chemical / General Hydraulic Oil / Thermal Media Oil | Water / Air | Water / Air | - | - | - | Water / Air | Air | Air | Water / Air | - | Water / Air / Chemical / General Hydraulic Oil / Thermal Media Oil | Water / Air / Chemical | Water / Air / Chemical | Water / Air | Water / Air / General Hydraulic Oil | Water / Air | Air | Air | Air | Water / Air | Water / Air | Water / Air / General Hydraulic Oil | Water / Air | Water / Air / Chemical | Water / Air | Water / Air | Water / Air | Water / Air / Chemical | Water / Air / Chemical / General Hydraulic Oil / Thermal Media Oil | Water / Air / Chemical / General Hydraulic Oil / Thermal Media Oil | Water / Air / Chemical |

| O.D. D(Ø) | 3.18 ~ 16 | 3.18 ~ 12 | 3.18 ~ 16 | 1" ~ 9/16" | 3.18 ~ 16 | 6 ~ 12 | 3.2 ~ 12 | 4 ~ 16 | 1" ~ 9/16" | 4 ~ 10 | 3 ~ 16 | 4 ~ 12 | 3.18 ~ 12 | 1" ~ 9/16" | 4 ~ 16 | 6 ~ 12 | - | - | - | 1.8 ~ 16 | 4 ~ 12 | 8 ~ 16 | - | - | 1" ~ 7/16" | 1" ~ 5/16" | 1/2" ~ 7/16" | 4 ~ 12 | 4 ~ 16 | 4 ~ 12 | 4 ~ 12 | 8 ~ 14 | 8 | 6 ~ 12 | 6 ~ 12 | 4 ~ 16 | 3.5 ~ 6 | 2 ~ 10 | 6 ~ 12 | 3.18 ~ 16 | 4 ~ 12 | 1" ~ 9/16" | 1-3/8" ~ 26 | 1" ~ 62 | 1" ~ 25 |

| I.D. [Distinction] | ~2 ~ ~10 | ~2 ~ ~20 | ~3 ~ ~15 | - | ~2 ~ ~15 | ~3 ~ ~8 | - | ~3 ~ ~15 | - | ~3 ~ ~8 | ~2 ~ ~15 | ~3 ~ ~8 | - | - | - | - | - | - | - | 1 or Less ~ ~15 | ~2 ~ ~8 | ~5 ~ ~15 | - | - | - | - | - | - | - | ~2 ~ ~8 | ~2 ~ ~8 | ~4 ~ ~8 | ~5 | ~4 ~ ~9 | ~4 ~ ~9 | ~3 ~ ~15 | ~2 ~ ~4 | 1 or Less ~ ~20 | ~4 ~ ~8 | ~3 ~ ~15 | ~3 ~ ~10 | - | - | - | - |

| I.D. d(Ø) | 2 ~ 10 | 2 ~ 10 | 2.5 ~ 12 | 1" ~ 5/16" | 1.6 ~ 13 | 3 ~ 8 | 2 ~ 9 | 2.5 ~ 13 | 1" ~ 5/16" | 2.5 ~ 8 | 2 ~ 12 | 2.5 ~ 8 | - | 1" ~ 5/16" | 2.5 ~ 11 | 4 ~ 8 | - | - | - | 1 ~ 11 | 2 ~ 8 | 5 ~ 11 | - | - | 1/2" ~ 5/16" | 1" ~ 3/16" | 1/2" ~ 3/16" | 2.5 ~ 9 | 2.5 ~ 12.8 | 2 ~ 8 | 2 ~ 8 | 4 ~ 8 | 5 | 4 ~ 8.5 | 4 ~ 9 | 2.5 ~ 13 | 2 ~ 3.5 | 1 ~ 8 | 4 ~ 8 | 2.5 ~ 13 | 2.5 ~ 9 | 1" ~ 5/16" | 1" ~ 19 | 1-1/2" ~ 50 | 1 ~ 20 |

| Number of Bores(per piece) | - | - | - | - | - | - | - | 1 | - | - | - | - | - | - | - | - | - | - | - | 1 | - | 1 | - | - | - | - | - | - | - | 1 | 2 ~ 8 | - | 1 | - | - | - | - | 1 | 1 | - | - | - | - | - | - |

| Material, Urethane | Polyurethane | - | - | - | - | - | - | - | - | - | Polyurethane | Polyurethane | - | - | Polyurethane | Incombustible Polyurethane | - | - | - | Polyurethane | Polyurethane | Polyurethane | - | - | - | - | - | - | - | Polyurethane | Polyurethane | - | Polyurethane | - | - | - | Polyurethane | - | Polyurethane | - | - | - | - | - | - |

| Material: Nylon | - | - | Nylon 12 | - | Pressure Resistant Nylon | Others | Nylon (Polyamide) | Soft Nylon | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | Nylon (Polyamide) | - | - | - | - | - | - | Soft Nylon | - | - | - | Nylon 12 | - | - | - | - | - |

| Material, Fluororesin | - | Standard Fluororesin | - | - | - | - | - | - | - | Soft Fluororesin | - | - | Standard Fluororesin | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | Standard Fluororesin | - | - | Soft Fluororesin | - | - | - | - |

| Operating Environment | Standard | Standard / Heat Resistance / Chemical Resistance | Standard | Standard / Water Resistance / Chemical Resistance | Standard / Abrasion Resistance / Oil Resistance / Chemical Resistance | Standard | Abrasion Resistance / Oil Resistance | Standard / Mold Cooling / Water Resistance / Pressure Resistance / Abrasion Resistance | Standard / Water Resistance / Oil Resistance / Chemical Resistance | Standard / Abrasion Resistance / Chemical Resistance | Standard | Standard | Standard / Heat Resistance / Chemical Resistance | Standard / Water Resistance / Oil Resistance / Chemical Resistance | Water Resistance / Abrasion Resistance | Sputter Resistant | - | - | - | Standard / Water Resistance | Standard / For Vacuum / Abrasion Resistance / Oil Resistance | Standard / Water Resistance / Abrasion Resistance / Oil Resistance | Standard | - | Standard / Water Resistance / Oil Resistance / Chemical Resistance | Standard / Water Resistance / Chemical Resistance | Standard / Water Resistance / Chemical Resistance | Pressure Resistance / Abrasion Resistance / Low Temp. Resistance / Weather Resistance | Pressure Resistance | Standard / Water Resistance / For Vacuum / Abrasion Resistance / Oil Resistance | Standard / For Vacuum / Abrasion Resistance / Oil Resistance | Standard / Sputter Resistant / Water Resistance / For Vacuum / Heat Resistance / Oil Resistance | Standard / Pressure Resistance / Heat Resistance / Abrasion Resistance / Low Temp. Resistance | Standard | Standard / Water Resistance / Weather Resistance | Standard / Pressure Resistance / Heat Resistance / Abrasion Resistance / Oil Resistance / Low Temp. Resistance / Chemical Resistance | Standard / Heat Resistance / Abrasion Resistance / Low Temp. Resistance | Standard / Heat Resistance / Chemical Resistance | Standard / Sputter Resistant | Standard | Standard / Chemical Resistance | Standard / Water Resistance / Chemical Resistance | Standard / Water Resistance / Oil Resistance / Chemical Resistance | Standard / Water Resistance / Oil Resistance / Chemical Resistance | Standard / Water Resistance / Chemical Resistance |

| O.D. (2nd Core) | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - |

| O.D. (3rd Core) | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - |

| O.D. (4th Core) | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - |

| I.D. (2nd Core) | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - |

| I.D. (3rd Core) | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - |

| I.D. (4th Core) | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - |

| Types of Related components | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | Insert | - | - | - | - | - | members for completion | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - |

Loading...

Configure

Stock

-

- Show Stock Products

Specification/Dimensions

-

Type

-

Material

-

Cutting Service Usage

- Yes

- No

-

Color

-

O.D. [Distinction]

-

Applicable Fluid

-

Metric / Inch

-

O.D. D(Ø)

- 0.090"

- 1/8"

- 5/32"

- 3/16"

- 0.205"

- 7/32"

- 1/4"

- 0.256"

- 5/16"

- 0.319"

- 3/8"

- 7/16"

- 0.441"

- 1/2"

- 17/32"

- 9/16"

- 0.579"

- 5/8"

- 11/16"

- 3/4"

- 13/16"

- 7/8"

- 1"

- 1-1/8"

- 1-1/4"

- 1-3/8"

- 1-1/2"

- 1-3/4"

- 2"

- 2-1/2"

- 3"

- 3-1/2"

- 1.6

- 1.7

- 1.8

- 10

- 10.2

- 10mm

- 11

- 11mm

- 12

- 12.2

- 12.5

- 12.7

- 12mm

- 13

- 13.5

- 13.5mm

- 13mm

- 14

- 14.2

- 14mm

- 15

- 16

- 16mm

- 17

- 18

- 18mm

- 2

- 2.5

- 20

- 22

- 23

- 24

- 25

- 25.4

- 26

- 28

- 29

- 3

- 3.17

- 3.18

- 3.2

- 3.5

- 34

- 35

- 4

- 4.5

- 4.76

- 42

- 47

- 48

- 4mm

- 5

- 5.95

- 52

- 57

- 5mm

- 6

- 6.35

- 62

- 7

- 7.6

- 7.85

- 7.94

- 7mm

- 8

- 8.2

- 8mm

- 9

- 9.53

- 9mm

-

I.D. [Distinction]

-

I.D. d(Ø)

-

Number of Bores(per piece)

-

Material, Urethane

-

Material: Nylon

-

Material, Fluororesin

-

Operating Environment

-

O.D. (2nd Core)

-

O.D. (3rd Core)

-

O.D. (4th Core)

-

I.D. (2nd Core)

-

I.D. (3rd Core)

-

I.D. (4th Core)

-

Types of Related components

Narrow search by specifying Manufacturer

CAD

-

- 2D

- 3D

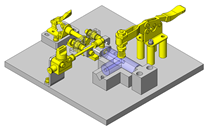

Application example related to this category

Related Categories to Tubes & Tube Accessories

-

- Cylinders, Rotary Actuators

- Cylinder Connecting Components

- Filters, Regulators, Lubricators

- Solenoid Valves

- Dryers for Pneumatics

- Pneumatic Pipe Fittings

- Flow Controls & Throttle Valves

- Manual-Type Valves, Mechanical-Type Valves

- Pneumatic Pipe Fittings

- Pressure, Flow Rate Sensors

- Silencers

- Compressors, Blowers

- Solenoid Valves for Fluid & Air-Operated Valves

- Tubes & Tube Accessories

- Other Pneumatic Devices

-

How can we improve?

How can we improve?

While we are not able to respond directly to comments submitted in this form, the information will be reviewed for future improvement.

Customer Privacy Policy

Thank you for your cooperation.

While we are not able to respond directly to comments submitted in this form, the information will be reviewed for future improvement.

Please use the inquiry form.

Customer Privacy Policy