(!)Due to Microsoft's end of support for Internet Explorer 11 on 15/06/2022, this site does not support the recommended environment.

Our Business Hours:

Mon. - Fri. 8 a.m. - 6 p.m.

Mon. - Fri. 8 a.m. - 6 p.m.

All Categories

Categories

- Automation Components

- Linear Motion

- Rotary Motion

- Connecting Parts

- Rotary Power Transmission

- Motors

- Conveyors & Material Handling

- Locating, Positioning, Jigs & Fixtures

- Inspection

- Sensors, Switches

- Pneumatics, Hydraulics

- Vacuum Components

- Hydraulic Equipment

- Spray Equipment And Accessories

- Pipe, Tubes, Hoses & Fittings

- Modules, Units

- Heaters, Temperature Control

- Aluminum Extrusions, Framing, Support & Posts

- Casters, Leveling Mounts, Posts

- Doors, Cabinet Hardware

- Springs, Shock Absorbers

- Adjustment/Fastening Components, Pins, Magnets

- Antivibration, Soundproofing Materials, Safety Products

- Fasteners

- Materials

- Wiring Components

- LAN Cables / Industrial Network Cables

- Equipment Specific Cables

- Cordsets

- Computer & AV Cables

- Wire/Cable

- Connector (General Purpose)

- Crimp Terminal Components

- Cable Organization

- Cable Gland Components

- Cable Bushing/Clip/Sticker

- Screw/Spacer

- Cable accessories

- Tube

- Electrical Conduits

- Duct/Wiring

- Electrical Wiring Tools

- Dedicated tools

- Soldering supplies

- Electrical & Controls

- Cutting Tools

- Carbide End Mill

- HSS End Mill

- Concrete Drill Bits

- Milling Cutter Insert / Holder

- Core Drill Bits

- Customized Straight Blade End Mill

- Dedicated Cutter

- Crinkey Cutters

- Turning Tool

- Drill

- Cutting Tool Accessories

- Screw Hole Related Tools

- Reamer

- Electric Drill Bits

- Chamfering, Centering Tool

- Hole Saws

- Magnetic Drill Press Cutters

- Step Drills

- Wood Drills & Cutters

- Processing Tools

- packing & logistics storage supplies

- Safety Products

- research and development & cleanroom supplies

- Press Die Components

- Plastic Mold Components

- Ejector Pins

- Sleeves, Center Pins

- Core Pins

- Sprue bushings, Gates, and other components

- Date Mark Inserts, Recycle Mark Inserts, Pins with Gas Vent

- Undercut, Plates

- Leader Components, Components for Ejector Space

- Mold Opening Controllers

- Cooling or Heating Components

- Accessories, Others

- Components of Large Mold, Die Casting

- Injection Molding Components

- Purging Agent

- Injection Molding Machine Products

- Accessories of Equipment

- Auxiliary Equipment

- Air Nippers

- Air Cylinders

- Air Chuck for Runner

- Chuck Board Components

- Frames

- Suction Components

- Parallel Air Chuck

- Special Air Chuck

- Mold Maintenance

- Heating Items

- Heat Insulation Sheets

- Couplers, Plugs, One-touch Joints

- Tubes, Hoses, Peripheral Components

Applications

Brands

- Webcode Seach | Series

-

#CODE

- Discontinued Products

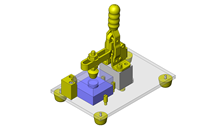

Locating Pins - Round or diamond shaped head, tapered tip with screw mounting hole and straight shank.

- Lead Time Reduction

This type of locating pin fixes the pin body with a screw. As the screw can be tightened from the top of the part, it can be used in places where screws cannot be used from the back side. P/B dimensions configurable in 0.1 and 1mm intervals. Constructed of heat-treated 4137 alloy steel, no surface treatment.

- METRIC

- inCAD Components

Part Number

Configured Part Number is shown.

・Materials

| Type | Shape | [ M ]Material | [ S ]Surface Treatment | [ H ]Hardness | |

| B Selectable | B Configurable | ||||

| LBNA | LBNFA | Round | 4137 Alloy Steel | - | Treated Hardness: 35~40HRC |

| LBND | - | Diamond | |||

Specifications

| Part Number | - | P | - | B | - | G | |

| LPZ5 JPMA15 LBNA20 | - - | P16.00 P30.0 | - - | B25.5 B10 | - | G15 | (Screw Mounted) (Pilot) (Large Screw Mounted) |

| Part Number | P 0.1mm Increment | B | ℓ | W | d1 | d2 | Applicable Screw | |||

| Type | Dg6 | Selection | 1mm Increment | |||||||

| LBNA (Round) LBND (Diamond) LBNFA (Round) | 16 | -0.006 -0.017 | 22.0~24.9 | 5 10 15 20 | - | 7.5 | 7 | 11 | 6.6 | M 6 |

| 20 | -0.007 -0.020 | 25.0~29.9 | 5~20 | 11 | 10 | 14 | 9 | M 8 | ||

| 30.0~37.9 | 13 | 17.5 | 11 | M10 | ||||||

| 38.0~39.9 | 16 | 12 | 20 | 14 | M12 | |||||

| 40.0~49.9 | 20 | 16 | ||||||||

| 50.0~59.9 | 25 | 20 | ||||||||

| 30 | 60.0~80.0 | 35 | 28 | |||||||

Part Number

CAD Data download and 3D preview are not available because the part number has not yet been determined.

- *In order to open the CAD Data download and 3D preview screen, the part number must be fixed.

- Please confirm the part number from "Specification / Dimension"on the left side, and then perform the CAD Data Download / 3D Preview operation.

Loading...

| Part Number |

|---|

| LBNA16-P[22-24.9/0.1]-B[5,10,15,20] |

| LBNA20-P[25-59.9/0.1]-B[5,10,15,20] |

| LBNA30-P[60-80/0.1]-B[5,10,15,20] |

| LBND16-P[22-24.9/0.1]-B[5,10,15,20] |

| LBND16-P[22-24.9/0.1]-P[5,10,15,20] |

| LBND20-P[25-59.9/0.1]-B[5,10,15,20] |

| LBND30-P[60-80/0.1]-B[5,10,15,20] |

| LBNFA20-P[25-59.9/0.1]-B[5-20/1] |

| LBNFA30-P[60-80/0.1]-B[5-20/1] |

Loading...

Example

Basic Information

| Basic Shape | Screw Mounted | Head Tip Shape | Tapered | Drive | Screw Mounted |

|---|---|---|---|---|---|

| Shank Style | Straight(Press Fit) | Material | 4137 Alloy Steel | Heat Treatment | Hardened |

| Surface Finish | No | Tolerance of Positioning Side Outer Diameter | 0/-0.05 | Shank Dia. Tolerance | g6 |

Specification/Dimensions

-

Head Shape

-

Round

Round -

Diamond

Diamond

-

-

Positioning Side Outer Diameter P(mm)

-

Mounted Side Outer Diameter D(mm)

-

Positioning Part Length B(mm)

-

type

- LBNA

- LBND

- LBNFA

-

CAD

- 2D

- 3D

Days to Ship

-

- All

- 9 Days or Less

Specify Alterations

- The specifications and dimensions of some parts may not be fully covered. For exact details, refer to manufacturer catalogs .

Additional Products in this Category

- Large Head Locating Pins - Round or diamond shaped head, tapered tip and internally threaded shank.

- Small Head Locating Pins - Round or diamond shaped head, spherical tip and internally threaded shank.

- Large Head Locating Pins - Round head, flat tip and straight shank configurable P/L/B dimensions.

- Height Adjustment Blocks - Conical flange, flat tip, standard or with sensor hole.

- Large Head Locating Pins - Round or diamond head, tapered tip with hole or drilled, externally threaded shank.

- Large Head Locating Pins - Round head, spherical tip, externally threaded shank.

- Large Head Locating Pins in Inches - Tapered and vented tip, externally threaded shank.

- Small Diameter Locating Pins - Spring loaded, straight shank, round head.

Complementary Products

Tech Support

- Technical Support

- Tel:+52-442-672-7661 ext. 2 then wait and dial 4

E-mail: soportetecnico@misumimex.com - Mon. - Fri. 8 a.m. - 6 p.m.

- Technical Inquiry

How can we improve?

How can we improve?

While we are not able to respond directly to comments submitted in this form, the information will be reviewed for future improvement.

Customer Privacy Policy

Thank you for your cooperation.

While we are not able to respond directly to comments submitted in this form, the information will be reviewed for future improvement.

Please use the inquiry form.

Customer Privacy Policy