(!)Due to Microsoft's end of support for Internet Explorer 11 on 15/06/2022, this site does not support the recommended environment.

Mon. - Fri. 8 a.m. - 6 p.m.

All Categories

Categories

- Automation Components

- Linear Motion

- Rotary Motion

- Connecting Parts

- Rotary Power Transmission

- Motors

- Conveyors & Material Handling

- Locating, Positioning, Jigs & Fixtures

- Inspection

- Sensors, Switches

- Pneumatics, Hydraulics

- Vacuum Components

- Hydraulic Equipment

- Spray Equipment And Accessories

- Pipe, Tubes, Hoses & Fittings

- Modules, Units

- Heaters, Temperature Control

- Aluminum Extrusions, Framing, Support & Posts

- Casters, Leveling Mounts, Posts

- Doors, Cabinet Hardware

- Springs, Shock Absorbers

- Adjustment/Fastening Components, Pins, Magnets

- Antivibration, Soundproofing Materials, Safety Products

- Fasteners

- Materials

- Wiring Components

- LAN Cables / Industrial Network Cables

- Equipment Specific Cables

- Cordsets

- Computer & AV Cables

- Wire/Cable

- Connector (General Purpose)

- Crimp Terminal Components

- Cable Organization

- Cable Gland Components

- Cable Bushing/Clip/Sticker

- Screw/Spacer

- Cable accessories

- Tube

- Electrical Conduits

- Duct/Wiring

- Electrical Wiring Tools

- Dedicated tools

- Soldering supplies

- Electrical & Controls

- Cutting Tools

- Carbide End Mill

- HSS End Mill

- Concrete Drill Bits

- Milling Cutter Insert / Holder

- Core Drill Bits

- Customized Straight Blade End Mill

- Dedicated Cutter

- Crinkey Cutters

- Turning Tool

- Drill

- Cutting Tool Accessories

- Screw Hole Related Tools

- Reamer

- Electric Drill Bits

- Chamfering, Centering Tool

- Hole Saws

- Magnetic Drill Press Cutters

- Step Drills

- Wood Drills & Cutters

- Processing Tools

- packing & logistics storage supplies

- Safety Products

- research and development & cleanroom supplies

- Press Die Components

- Plastic Mold Components

- Ejector Pins

- Sleeves, Center Pins

- Core Pins

- Sprue bushings, Gates, and other components

- Date Mark Inserts, Recycle Mark Inserts, Pins with Gas Vent

- Undercut, Plates

- Leader Components, Components for Ejector Space

- Mold Opening Controllers

- Cooling or Heating Components

- Accessories, Others

- Components of Large Mold, Die Casting

- Injection Molding Components

- Purging Agent

- Injection Molding Machine Products

- Accessories of Equipment

- Auxiliary Equipment

- Air Nippers

- Air Cylinders

- Air Chuck for Runner

- Chuck Board Components

- Frames

- Suction Components

- Parallel Air Chuck

- Special Air Chuck

- Mold Maintenance

- Heating Items

- Heat Insulation Sheets

- Couplers, Plugs, One-touch Joints

- Tubes, Hoses, Peripheral Components

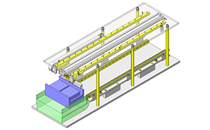

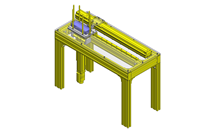

Applications

Brands

- Webcode Seach | Series

-

#CODE

- Discontinued Products

Heavy Load Linear Guides - Standard block, stainless steel. Interchangeable. (Part Numbers)

- Volume Discount

Heavy duty stainless steel linear guide. Standard degree of precision. It has resin retainers without mutual contact between its bearings, which reduce noise during operation at high speeds and provide a smoother movement. Blocks and rails can be purchased separately or in an assembly.

- inCAD Components

Part Number

Configured Part Number is shown.

[ ! ]For L Dimension Configurable Type, G dimensions differ from those shown in the table below. For details, see >> Click here.

| [ M ]Material [ H ]Hardness | Type | Block | Rail | L Dimension | |

| 1 block | 2 blocks | ||||

| Stainless Steel (440C Stainless Steel) 57HRC~ | SSXRZ | SSX2RZ | SSXRB | SSRZL | Selectable |

| SSXRLZ | SSX2RLZ | SSRZLF | Configurable | ||

Specifications

[ ! ]For L Dimension Configurable Type, G dimensions differ from those shown in the table below. For details, see >> Click here.

| Part Number | L | Block Dimension | Guide Rail Dimension | |||||||||||||||||

| Type | H | W | L1 | B | C | Sxℓ | L2 | K | T | Grease Fitting | H1 | W1 | W2 | Counterbored Hole | F | G | ||||

| 1 block | 2 blocks | Mounting Hole | E | T1 | d1xd2xh | |||||||||||||||

| SSXRZ SSXRLZ (Block) SSXRB | SSX2RZ SSX2RLZ (Rail) SSRZL SSRZLF | 24 | 100~1480 (160) | 34 | 56.8 | 26 | 26 | M4x6 | 40 | 19.4 | 10 | Ø3 | 3 | 6 | 12.5 | 15 | 9.5 | 3.5x6x4.5 | 60 | 20 |

| 28 | 160~1480 (220) | 42 | 65.2 | 32 | 32 | M5x7 | 48 | 22 | 12 | M6xP0.75 | 11 | 5.5 | 15.5 | 20 | 11 | 6x9.5x8.5 | 60 | 20 | ||

| 33 | 160~1480 (220) | 48 | 81.6 | 35 | 35 | M6x9 | 60 | 26 | 12 | M6xP0.75 | 11 | 7 | 18 | 23 | 12.5 | 7x11x9 | 60 | 20 | ||

Materials

| [ M ]Material [ H ]Hardness | Type | Block | Rail | L Dimension | |

| 1 block | 2 blocks | ||||

| Stainless Steel (440C Stainless Steel) 57HRC~ | SSXRZ | SSX2RZ | SSXRB | SSRZL | Selectable |

| SSXRLZ | SSX2RLZ | SSRZLF | Configurable | ||

| Part Number | - | L |

| SSXRZ28 | - | 640 |

[ ! ]Blocks are equipped with retainers (wire) to prevent balls from derailing. For blocks >> Click here

[ ! ]For Interchangeable, Light Preload Type, rails and blocks can be interchanged.

[ ! ]Straight grooves are provided on datum planes. Be sure to match the datum lines when using.

[ ! ]Rails cannot be connected end to end.

[ ! ]Running parallelism is the value measured after the rail is mounted (it is not the value measured before the rails are fastened with screws.).

■Others

· Filled with Lithium soap based grease (Alvania Grease S2 by Showa Shell Sekiyu K.K).

· Grease Fittings: Straight Type for H24 and Angled Type for H28 and H33.

· Grease Fitting is screw-in type, and thus, can be repositioned.

· For Operating Life Calculation >> Click here

Price list

| Quantity | 1~4 | 5~9 | 10~19 | 20 or More |

| Discount Rate | Unit Price | Unit Price | 5% | 12% |

| Days to Ship | Standard | 5 additional days | To Be Quoted | |

| H | L | Unit Price | |||

| Set | Rail | Block | |||

| SSXRZ | SSX2RZ | SSRZL | SSXRB | ||

| 24 | 100 | 12,480 | - | 3,800 | 9,380 |

| 160 | 13,990 | 22,870 | 5,400 | ||

| 220 | 15,500 | 24,380 | 7,000 | ||

| 280 | 17,020 | 25,900 | 8,590 | ||

| 340 | 18,530 | 27,410 | 10,190 | ||

| 400 | 20,040 | 28,920 | 11,790 | ||

| 460 | 21,550 | 30,430 | 13,390 | ||

| 520 | 23,060 | 31,940 | 14,980 | ||

| 580 | 24,580 | 33,460 | 16,580 | ||

| 640 | 26,090 | 34,970 | 18,180 | ||

| 700 | 27,600 | 36,480 | 19,770 | ||

| 760 | 29,110 | 37,990 | 21,370 | ||

| 820 | 30,620 | 39,500 | 22,970 | ||

| 880 | 32,140 | 41,020 | 24,570 | ||

| 940 | 33,650 | 42,530 | 26,160 | ||

| 1000 | 35,160 | 44,040 | 27,760 | ||

| 1060 | 36,670 | 45,550 | 29,360 | ||

| 1120 | 38,180 | 47,060 | 30,950 | ||

| 1180 | 39,700 | 48,580 | 32,550 | ||

| 1240 | 41,210 | 50,090 | 34,150 | ||

| 1300 | 42,720 | 51,600 | 35,750 | ||

| 1360 | 44,230 | 53,110 | 37,340 | ||

| 1420 | 45,740 | 54,620 | 38,940 | ||

| 1480 | 47,260 | 56,140 | 40,540 | ||

| 28 | 160 | 15,660 | - | 5,640 | 10,900 |

| 220 | 17,260 | 27,580 | 7,330 | ||

| 280 | 18,860 | 29,180 | 9,020 | ||

| 340 | 20,460 | 30,780 | 10,710 | ||

| 400 | 22,060 | 32,380 | 12,400 | ||

| 460 | 23,650 | 33,970 | 14,090 | ||

| 520 | 25,250 | 35,570 | 15,770 | ||

| 580 | 26,850 | 37,170 | 17,460 | ||

| 640 | 28,450 | 38,770 | 19,150 | ||

| 700 | 30,050 | 40,370 | 20,840 | ||

| 760 | 31,650 | 41,970 | 22,530 | ||

| 820 | 33,250 | 43,570 | 24,220 | ||

| 880 | 34,840 | 45,160 | 25,900 | ||

| 940 | 36,440 | 46,760 | 27,590 | ||

| 1000 | 38,040 | 48,360 | 29,280 | ||

| 1060 | 39,640 | 49,960 | 30,970 | ||

| 1120 | 41,240 | 51,560 | 32,660 | ||

| 1180 | 42,830 | 53,150 | 34,350 | ||

| 1240 | 44,430 | 54,750 | 36,040 | ||

| 1300 | 46,030 | 56,350 | 37,720 | ||

| 1360 | 47,630 | 57,950 | 39,410 | ||

| 1420 | 49,230 | 59,550 | 41,100 | ||

| 1480 | 50,830 | 61,150 | 42,790 | ||

| 33 | 160 | 17,450 | - | 6,070 | 12,360 |

| 220 | 19,190 | 30,890 | 7,920 | ||

| 280 | 20,950 | 32,650 | 9,770 | ||

| 340 | 22,690 | 34,390 | 11,610 | ||

| 400 | 24,440 | 36,140 | 13,460 | ||

| 460 | 26,190 | 37,890 | 15,310 | ||

| 520 | 27,940 | 39,640 | 17,160 | ||

| 580 | 29,690 | 41,390 | 19,010 | ||

| 640 | 31,440 | 43,140 | 20,850 | ||

| 700 | 33,190 | 44,890 | 22,700 | ||

| 760 | 34,940 | 46,640 | 24,550 | ||

| 820 | 36,690 | 48,390 | 26,400 | ||

| 880 | 38,440 | 50,140 | 28,250 | ||

| 940 | 40,190 | 51,890 | 30,100 | ||

| 1000 | 41,940 | 53,640 | 31,940 | ||

| 1060 | 43,690 | 55,390 | 33,790 | ||

| 1120 | 45,440 | 57,140 | 35,640 | ||

| 1180 | 47,190 | 58,890 | 37,490 | ||

| 1240 | 48,940 | 60,640 | 39,340 | ||

| 1300 | 50,690 | 62,390 | 41,180 | ||

| 1360 | 52,440 | 64,140 | 43,030 | ||

| 1420 | 54,190 | 65,890 | 44,880 | ||

| 1480 | 55,940 | 67,640 | 46,730 | ||

| H | Unit Price | ||

| Set | Rails | ||

| SSXRLZ | SSX2RLZ | SSRZLF | |

| 24 | 600 | 600 | 650 |

| 28 | 700 | 700 | 750 |

| 33 | 800 | 800 | 850 |

Alterations

More Information

Linear Guide Clamps >> Click here

Rail Height Adjusting Blocks >> Click here, Click here

■Stopper Bolts >> Click here

■Block Stopper Plates >> Click here

■Rail Mounting Hole Caps >> Click here

■Rail Push Plates >> Click here

■Linear Locks >> Click here

■Linear Guide Lock Units >> Click here

Technical Information

Characteristics of Linear Guides

- Linear guides utilize steel balls that roll on ground raceways, and the balls are recirculated using plastic return caps.

- End seals prevent foreign materials from entering into the blocks.

- Load ratings are the same for all four directions (radial, reverse-radial, and lateral directions). Can be used in any orientation.

Preload (Radial Clearance)

| Type of guide | Preload | Height H Dimension | Radial Clearance (µm) |

|---|---|---|---|

| Linear guide medium/heavy load | Normal clearance | 24 | -4 ~ +2 |

| 28 | -5 ~ +2 | ||

| 33 | -6 ~ +3 | ||

| Light preload | 24,28 | -4 ~ 0 | |

| 30 ~ 42 | -5 ~ 0 | ||

| 42* | -7 ~ 0 |

* marked size is for Ultra Heavy / Extra Super Heavy Load

- Clearance and preload of MISUMI Linear Guides are controlled with minute ball size adjustments.

- Increased rigidity and reduced elastic deformation will result by preloading (negative clearance).

- In general, selecting some preloads would have a positive effect on the accuracy and service life of the Linear Guides.

- Blocks and rails manufactured by MIUSMI guarantee their own radial clearance (preload) and accuracy as sets of blocks and rails. Be sure to use the blocks and rails in sets.

Types of Greases

The following types of greases are used in MISUMI linear guides.

| Grease | Linear Guide | Grease Model | Features |

|---|---|---|---|

| Standard | Miniature | Multemp Grease PS2 (Manufactured by Kyodo Yushi) | Grease with excellent low temperature and low torque properties. |

| Miniature with MX lubrication unit | Tufflix MP2 (Manufactured by JX Nippon Oil & Energy) | Reduces temperature rise in the bearing area; extends bearing life and reduces grease replenishment interval and maintenance work. | |

| Medium Load Heavy Load | Albania Grease S2 (Manufactured by Showa Shell Sekiyu) | It has excellent lubrication and shows excellent performance under normal and heavy load conditions. | |

| Type L | Miniature/Medium/Heavy Load | ET-100K (Manufactured by Kyodo Yushi) | It has excellent heat resistance, oxidation stability, adhesion and tackiness. It is also a low dispersion, low leakage grease. |

| Type G | LG2 (Manufactured by NSK Ltd.) | It produces little dust and has excellent wear resistance and rust resistance properties. |

Maintenance

The grease forms an oil film on the steel balls and on the slideways of the linear guide, reducing friction.

Loss and deterioration of the grease will greatly affect the service life of the linear guide, so it must be lubricated on time depending on the conditions of use.

MISUMI linear guides are lubricated with standard grease at the time of shipment, so they can be used as is.

Recommended lubrication intervals

Lubricate every 6 months. If linear guide is used for long distances, it is recommended to lubricate every 3 months, or if it is used more than 1000 km in a period, we recommend every 1000 km.

*The above is the distance-based lubrication interval. If the grease deteriorates or is heavily contaminated due to the operating environment, it may be necessary to shorten the lubrication interval.

By using a lubrication unit, it is possible to extend the lubrication interval considerably.

Permissible loads

| H | Basic Load Rating | Allowable Static Moment | Mass | ||||

|---|---|---|---|---|---|---|---|

| C (Dynamic) kN | Co (Static) kN | MA N・m | MB N・m | MC N・m | Block kg | Guide Rails kg/m | |

| 24 | 7.9 | 15.6 | 74 | 62 | 78 | 0.20 | 1.4 |

| 28 | 11.1 | 21.8 | 124 | 104 | 149 | 0.28 | 2.3 |

| 33 | 17.9 | 33.5 | 242 | 203 | 266 | 0.51 | 3.1 |

kgf = N ・ 0.101972

kgf = kilograms force, N = Newton

Support Information

Shelf Life Information

For more information about the calculation of useful life, click here.

Mounting Hole Information

For more information about mounting holes and G-value, click here.

Installation Information

For more information about the installation click here.

Cautions

If the linear guides are handled incorrectly, the quality may deteriorate. When using MISUMI linear guides, consider the following points:

Be careful when removing the blocks

MISUMI linear guidesare equipped with a retainer, so that the balls will not fall out even if the block is removed from the rail. However, if the block is removed from the rail at high speed or inserted at an angle, the balls may fall out. Be careful when removing and installing the blocks.

Blocks and rails not sold separately

Linear guides MISUMI are only sold as a block and rail assembly. For resin retainer type only, blocks and rails can be purchased separately.

Please do not replace with another product

The radial clearance and accuracy of MISUMI linear guides are guaranteed as a block and rail assembly, so the accuracy is not guaranteed when combined with another product.

Please check the reference surface before installation.

Linear guides have reference planes on both the rail and the block (the side with a straight groove is provided). When installing the linear guide, correctly align this reference surface with the mounting reference surface of the table and base and secure it. For more details, refer to"Installation" in "Support Information".

Please do not add rails

MISUMI linear guides are shipped with chamfered edges on the end of the rail. The use of additional rails is not covered under warranty.

Secure all rail mounting holes.

The rail curvature is corrected with all mounting holes clamped. Accuracy is guaranteed under these conditions.

Accessories

| Clamping Units | Height Adjusting Blocks | |

|---|---|---|

| Economy Model | Standard Linear Guides Model | |

|  |  |

| Fall Prevention /Dust Protection | ||

| Stopper Bolt | Fall Prevention Plate | Hole Cap |

|  |  |

| Rail Fastening | ||

| Linear Guide Adjustment Unit | Linear Guide Locks | Linear Guide Lock Units |

|  |  |

Compatible Models

Part Number

CAD Data download and 3D preview are not available because the part number has not yet been determined.

- *In order to open the CAD Data download and 3D preview screen, the part number must be fixed.

- Please confirm the part number from "Specification / Dimension"on the left side, and then perform the CAD Data Download / 3D Preview operation.

| Part Number |

|---|

| SSRZL24-[100,160,220,280,340,400,460,520,580,640,700,760,820,880,940,1000,1060,1120,1180,1240,1300,1360,1420,1480] |

| SSRZL28-[160,220,280,340,400,460,520,580,640,700,760,820,880,940,1000,1060,1120,1180,1240,1300,1360,1420,1480] |

| SSRZL33-[160,220,280,340,400,460,520,580,640,700,760,820,880,940,1000,1060,1120,1180,1240,1300,1360,1420,1480] |

| SSRZLF24-[101-1479/1] |

| SSRZLF28-[161-1479/1] |

| SSRZLF33-[161-1479/1] |

| SSX2RLZ24-[161-1479/1] |

| SSX2RLZ28-[221-1479/1] |

| SSX2RLZ33-[221-1479/1] |

| SSX2RZ24-[160,220,280,340,400,460,520,580,640,700,760,820,880,940,1000,1060,1120,1180,1240,1300,1360,1420,1480] |

| SSX2RZ28-[220,280,340,400,460,520,580,640,700,760,820,880,940,1000,1060,1120,1180,1240,1300,1360,1420,1480] |

| SSX2RZ33-[220,280,340,400,460,520,580,640,700,760,820,880,940,1000,1060,1120,1180,1240,1300,1360,1420,1480] |

| SSXRB24 |

| SSXRB28 |

| SSXRB33 |

| SSXRLZ24-[101-1479/1] |

| SSXRLZ28-[161-1479/1] |

| SSXRLZ33-[161-1479/1] |

| SSXRZ24-[100,160,220,280,340,400,460,520,580,640,700,760,820,880,940,1000,1060,1120,1180,1240,1300,1360,1420,1480] |

| SSXRZ28-[160,220,280,340,400,460,520,580,640,700,760,820,880,940,1000,1060,1120,1180,1240,1300,1360,1420,1480] |

| SSXRZ33-[160,220,280,340,400,460,520,580,640,700,760,820,880,940,1000,1060,1120,1180,1240,1300,1360,1420,1480] |

Loading...

Basic Information

| Material | Stainless Steel | Preload | Light Preload-Interchangeable |

|---|

Specification/Dimensions

-

Set / Single Item

- Set

- Block Only

- Rail Only

-

Block Type

- Standard

- Standard

-

Rail Type

-

Standard

Standard

-

-

Rail Width W1(mm)

-

Unit Height H(mm)

-

No. of Blocks

- 1

- 2

-

Rail Length L(mm)

- 100

- 160

- 220

- 280

- 340

- 400

- 460

- 520

- 580

- 640

- 700

- 760

- 820

- 880

- 940

- 1000

- 1060

- 1120

- 1180

- 1240

- 1300

- 1360

- 1420

- 1480

[101-1479/1mm Unit(s)]

-

Nominal Part Number

-

Ball Arrangement

- Medium, Heavy Load Type with Plastic Retainers

-

Retainer

- Available

-

Lubrication Type

- Lithium Base Grease (Standard)

-

L Dimension Type

- Configurable Type

- Standard Type

-

type

- SSRZL

- SSRZLF

- SSX2RLZ

- SSX2RZ

- SSXRB

- SSXRLZ

- SSXRZ

-

CAD

- 2D

- 3D

Days to Ship

-

- All

- 10 Days or Less

- 12 Days or Less

Specify Alterations

- The specifications and dimensions of some parts may not be fully covered. For exact details, refer to manufacturer catalogs .

Frequently asked questions (FAQ)

- 質問: Are the block's ball bearings retained?

- 回答: Yes, all ball bearings are retained on Misumi linear guides.

Additional Products in this Category

- Miniature Linear Guides - Short block.

- Miniature Linear Guides - Wide track, standard block with dowel bolt holes.

- Miniature Linear Guides - Wide Track, Long Standard Block. With a slight slack.

- Miniature Linear Guides - Resistant to high temperatures.

- LM Guides - Standard guide, SHS model assembly.

- LM Guides - Miniature, model SRS-G assembly.

- LM Guides - Block Only, Model SSR.

- LM Guides - Block Only, SR Model.

Complementary Products

Tech Support

- Technical Support

- Tel:+52-442-672-7661 ext. 2 then wait and dial 4

E-mail: soportetecnico@misumimex.com - Mon. - Fri. 8 a.m. - 6 p.m.

- Technical Inquiry

How can we improve?

How can we improve?

While we are not able to respond directly to comments submitted in this form, the information will be reviewed for future improvement.

Customer Privacy Policy

Thank you for your cooperation.

While we are not able to respond directly to comments submitted in this form, the information will be reviewed for future improvement.

Please use the inquiry form.

Customer Privacy Policy