(!)Due to Microsoft's end of support for Internet Explorer 11 on 15/06/2022, this site does not support the recommended environment.

Mon. - Fri. 8 a.m. - 6 p.m.

All Categories

Categories

- Automation Components

- Linear Motion

- Rotary Motion

- Connecting Parts

- Rotary Power Transmission

- Motors

- Conveyors & Material Handling

- Locating, Positioning, Jigs & Fixtures

- Inspection

- Sensors, Switches

- Pneumatics, Hydraulics

- Vacuum Components

- Hydraulic Equipment

- Spray Equipment And Accessories

- Pipe, Tubes, Hoses & Fittings

- Modules, Units

- Heaters, Temperature Control

- Aluminum Extrusions, Framing, Support & Posts

- Casters, Leveling Mounts, Posts

- Doors, Cabinet Hardware

- Springs, Shock Absorbers

- Adjustment/Fastening Components, Pins, Magnets

- Antivibration, Soundproofing Materials, Safety Products

- Fasteners

- Materials

- Wiring Components

- LAN Cables / Industrial Network Cables

- Equipment Specific Cables

- Cordsets

- Computer & AV Cables

- Wire/Cable

- Connector (General Purpose)

- Crimp Terminal Components

- Cable Organization

- Cable Gland Components

- Cable Bushing/Clip/Sticker

- Screw/Spacer

- Cable accessories

- Tube

- Electrical Conduits

- Duct/Wiring

- Electrical Wiring Tools

- Dedicated tools

- Soldering supplies

- Electrical & Controls

- Cutting Tools

- Carbide End Mill

- HSS End Mill

- Concrete Drill Bits

- Milling Cutter Insert / Holder

- Core Drill Bits

- Customized Straight Blade End Mill

- Dedicated Cutter

- Crinkey Cutters

- Turning Tool

- Drill

- Cutting Tool Accessories

- Screw Hole Related Tools

- Reamer

- Electric Drill Bits

- Chamfering, Centering Tool

- Hole Saws

- Magnetic Drill Press Cutters

- Step Drills

- Wood Drills & Cutters

- Processing Tools

- packing & logistics storage supplies

- Safety Products

- research and development & cleanroom supplies

- Press Die Components

- Plastic Mold Components

- Ejector Pins

- Sleeves, Center Pins

- Core Pins

- Sprue bushings, Gates, and other components

- Date Mark Inserts, Recycle Mark Inserts, Pins with Gas Vent

- Undercut, Plates

- Leader Components, Components for Ejector Space

- Mold Opening Controllers

- Cooling or Heating Components

- Accessories, Others

- Components of Large Mold, Die Casting

- Injection Molding Components

- Purging Agent

- Injection Molding Machine Products

- Accessories of Equipment

- Auxiliary Equipment

- Air Nippers

- Air Cylinders

- Air Chuck for Runner

- Chuck Board Components

- Frames

- Suction Components

- Parallel Air Chuck

- Special Air Chuck

- Mold Maintenance

- Heating Items

- Heat Insulation Sheets

- Couplers, Plugs, One-touch Joints

- Tubes, Hoses, Peripheral Components

Applications

Brands

- Webcode Seach | Series

-

#CODE

- Discontinued Products

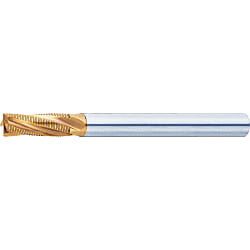

TSC Series Carbide Roughing End Mill, Fine Pitch/Long Regular Model

- Volume Discount

A long shank type that's ideal for deep engraving

- TS

- General Steel

- R (Regular)

Part Number

Configured Part Number is shown.

| Part Number |

|---|

| SN-TSC-LS-RFPR6-[20-65/1]-15 |

| SN-TSC-LS-RFPR8-[25-70/1]-20 |

| SN-TSC-LS-RFPR10-[30-70/1]-25 |

| SN-TSC-LS-RFPR12-[35-80/1]-30 |

| SN-TSC-LS-RFPR16-[45-90/1]-40 |

| SN-TSC-LS-RFPR20-[50-95/1]-45 |

| TSC-LS-RFPR5 |

| TSC-LS-RFPR6 |

| TSC-LS-RFPR8 |

| TSC-LS-RFPR8-6 |

| TSC-LS-RFPR10 |

| TSC-LS-RFPR10-8 |

| TSC-LS-RFPR12 |

| TSC-LS-RFPR12-10 |

| TSC-LS-RFPR13 |

| TSC-LS-RFPR14 |

| TSC-LS-RFPR16 |

| TSC-LS-RFPR18 |

| TSC-LS-RFPR20 |

Loading...

Specifications

| Model Number | Shank Diameter d |

Flute Length ℓ |

Overall Length L |

Number of Flutes | Figure | ||

| Outer Diameter D |

Shank Diameter d |

||||||

| TSC-LS-RFPR | 5 | — | 6 | 15 | 100 | 3 | 1 |

| 6 | — | 6 | 15 | 100 | 3 | 2 | |

| 8 | — | 8 | 20 | 100 | 4 | 2 | |

| 8 | 6 | 6 | 20 | 100 | 4 | 3 | |

| 10 | — | 10 | 25 | 100 | 4 | 2 | |

| 10 | 8 | 8 | 25 | 100 | 4 | 3 | |

| 12 | — | 12 | 30 | 125 | 4 | 2 | |

| 12 | 10 | 10 | 30 | 100 | 4 | 3 | |

| 13 | — | 12 | 30 | 125 | 4 | 3 | |

| 14 | — | 12 | 35 | 125 | 4 | 3 | |

| 16 | — | 16 | 40 | 125 | 4 | 2 | |

| 18 | — | 16 | 45 | 125 | 4 | 2 | |

| 20 | — | 20 | 45 | 150 | 4 | 2 |

[ ! ]For shank diameter (d) specifications listed in blue, specify both a outer diameter (D) and shank diameter (d).

For Cutting Conditions, Refer to >>Click here.

More Information

● It has a TS film coating with much greater oxidation resistance and hardness than conventional films, resulting in a longer operational life and is ideal for high speed machining / dry machining.

● It adopts a fine pitch nick that delivers a finish with good surface roughness after machining.

● The long shank models are ideal for machining deep grooves.

Basic Information

| Work Material | General Steel / Heat-Treated Steel / High-Hardness Steel ~ HRC55 / Stainless Steel / Cast Iron / Aluminum Alloy / Copper Alloy | Model | Roughing | Coating | For High Hardness (Silicone-Based) |

|---|---|---|---|---|---|

| Geometry | Ultra-Small R | Helix Angle (θ) | Weak Helix (15 to 25°) | Tolerance of OD(mm) | ±0.06 |

Specification/Dimensions

-

Outer Diameter (D)(φ)

-

Flute Length (ℓ)(mm)

-

Number of Flutes(sheet)

-

Shank Diameter (d)(mm)

-

Overall Length (L)(mm)

-

Length Under Neck (ℓ1)(mm)

-

Processing Applications

- Flat Surface

- Side Surface

- Groove

- Inclined Cutting

-

Additional Classification

- Standard Neck Relief

- Stocked Product

-

type

- SN-TSC-LS-RFPR

- TSC-LS-RFPR

Days to Ship

-

- All

- 8 Days or Less

- 10 Days or Less

Specify Alterations

- The specifications and dimensions of some parts may not be fully covered. For exact details, refer to manufacturer catalogs .

Additional Products in this Category

- TSC Series Carbide Roughing End Mill, 45° Spiral/Fine Pitch/Long Model

- Carbide Roughing End Mill for Aluminum Machining, 3-Flute/Regular Model

- DIA-HBC4 Carbide End Mill, Router Series for CFRP, Herringbone Type (4 Bottom Flutes)

- Roughing End Mill for Aluminum Machining AL-OCRL Type

- One Cut Rough DZ-OCRS

- SPSRD3ZA Vertical-Feed, Strengthened, Roughing SP Series Roughing Mill 3 Flutes / OK Coated

- SPEED/T 3/4 Flute 40° Roughing

- Ayame Router (Multi-Blade, Bar Type)

How can we improve?

How can we improve?

While we are not able to respond directly to comments submitted in this form, the information will be reviewed for future improvement.

Customer Privacy Policy

Thank you for your cooperation.

While we are not able to respond directly to comments submitted in this form, the information will be reviewed for future improvement.

Please use the inquiry form.

Customer Privacy Policy