(!)Due to Microsoft's end of support for Internet Explorer 11 on 15/06/2022, this site does not support the recommended environment.

Mon. - Fri. 8 a.m. - 6 p.m.

All Categories

Categories

- Automation Components

- Linear Motion

- Rotary Motion

- Connecting Parts

- Rotary Power Transmission

- Motors

- Conveyors & Material Handling

- Locating, Positioning, Jigs & Fixtures

- Inspection

- Sensors, Switches

- Pneumatics, Hydraulics

- Vacuum Components

- Hydraulic Equipment

- Spray Equipment And Accessories

- Pipe, Tubes, Hoses & Fittings

- Modules, Units

- Heaters, Temperature Control

- Aluminum Extrusions, Framing, Support & Posts

- Casters, Leveling Mounts, Posts

- Doors, Cabinet Hardware

- Springs, Shock Absorbers

- Adjustment/Fastening Components, Pins, Magnets

- Antivibration, Soundproofing Materials, Safety Products

- Fasteners

- Materials

- Wiring Components

- LAN Cables / Industrial Network Cables

- Equipment Specific Cables

- Cordsets

- Computer & AV Cables

- Wire/Cable

- Connector (General Purpose)

- Crimp Terminal Components

- Cable Organization

- Cable Gland Components

- Cable Bushing/Clip/Sticker

- Screw/Spacer

- Cable accessories

- Tube

- Electrical Conduits

- Duct/Wiring

- Electrical Wiring Tools

- Dedicated tools

- Soldering supplies

- Electrical & Controls

- Cutting Tools

- Carbide End Mill

- HSS End Mill

- Concrete Drill Bits

- Milling Cutter Insert / Holder

- Core Drill Bits

- Customized Straight Blade End Mill

- Dedicated Cutter

- Crinkey Cutters

- Turning Tool

- Drill

- Cutting Tool Accessories

- Screw Hole Related Tools

- Reamer

- Electric Drill Bits

- Chamfering, Centering Tool

- Hole Saws

- Magnetic Drill Press Cutters

- Step Drills

- Wood Drills & Cutters

- Processing Tools

- packing & logistics storage supplies

- Safety Products

- research and development & cleanroom supplies

- Press Die Components

- Plastic Mold Components

- Ejector Pins

- Sleeves, Center Pins

- Core Pins

- Sprue bushings, Gates, and other components

- Date Mark Inserts, Recycle Mark Inserts, Pins with Gas Vent

- Undercut, Plates

- Leader Components, Components for Ejector Space

- Mold Opening Controllers

- Cooling or Heating Components

- Accessories, Others

- Components of Large Mold, Die Casting

- Injection Molding Components

- Purging Agent

- Injection Molding Machine Products

- Accessories of Equipment

- Auxiliary Equipment

- Air Nippers

- Air Cylinders

- Air Chuck for Runner

- Chuck Board Components

- Frames

- Suction Components

- Parallel Air Chuck

- Special Air Chuck

- Mold Maintenance

- Heating Items

- Heat Insulation Sheets

- Couplers, Plugs, One-touch Joints

- Tubes, Hoses, Peripheral Components

Applications

Brands

- Webcode Seach | Series

-

#CODE

- Discontinued Products

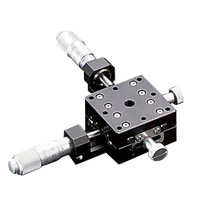

Manual XY-Axis Stages

| Days to Ship |

|

|---|

-

Manual XY-Axis Stages - Cross Roller Guide, High Accuracy, XYPG/XYPGN/XYPCG

MISUMI

Lightweight and High Precision Cross Roller Stages made of aluminum alloy.

- Volume Discount

- Lead Time Reduction

- inCAD Components

Days to Ship: 10 Days or more -

Manual XY-Axis Stages - Dovetail, Feed Screw, XYEG

MISUMI

XY-axis feed screw. Capable of 0.5mm fine feed.

- Volume Discount

- Lead Time Reduction

- inCAD Components

Days to Ship: 8 Days or more -

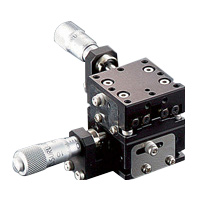

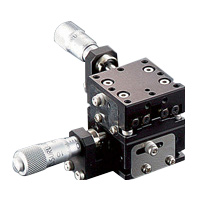

Manual XY-Axis Stages - Rectangular Dovetail, Rack and Pinion, High Accuracy, XYWG

MISUMI

Rectangular Dovetail Slide XY-Axis Stages with 18mm travel per knob rotation.

- Volume Discount

- inCAD Components

Days to Ship: 8 Days or more -

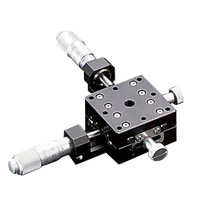

Manual XY-Axis Stages - Linear Ball Guide, High Accuracy, XYSG/XYSGB/XYSCG/XYSCGB

MISUMI

Low Temperature Black Chrome Plating Adopted for Surface Treatment. Suitable for Reflection Prevention.

- Volume Discount

- Lead Time Reduction

- inCAD Components

Days to Ship: 8 Days or more -

Manual XY-Axis Stages - Linear Ball Guide, Low Profile, High Accuracy, XYSSG/XYSSCG

MISUMI

Integrated Structure of XY Axes realized Further Thinness.

- Volume Discount

- inCAD Components

Days to Ship: 10 Days or more -

Manual XY-Axis Stages - Cross Roller Guide, Low Profile, XY/XYCRSC

MISUMI

Thin Stage with a micrometer head capable of 0.01mm resolution adjustments.

- Volume Discount

- New Pricing

- inCAD Components

Days to Ship: 8 Days or more -

Manual XY-Axis Stages - Cross Roller Guide, High Accuracy, Lightweight, B21

Suruga Seiki

A light weight, high accuracy cross roller guide type stage (XY-axis).[Features]・ The main material is aluminum, so it is lightweight

・ High-accuracy stage with high rigidity, low friction and excellent minute feeding

・ Size, feed position, orientation specifications, feed method can be selected as options

[Applications]・ Precision adjustment of cameras, microscopes, sensors and optical components

・ Positioning of production, assembly and inspection processes related to semiconductors and measuring instruments.- Volume Discount

Days to Ship: 8 Days or more -

Manual XY-Axis Stages - Dovetail, Rack and Pinion, B05/B06

Suruga Seiki

A rack and pinion type stage (XY-axis) that is ideal for making quick and large movements.

[Features]

・ It consists of a rack rail and a pinion gear, and can be moved greatly with 1 rotation of the handle

・ Ideal for easy alignment and evacuation

・ B05 adopts the original clamp and can be clamped with a single-action

・ With a vernier scale (0.1 mm)

[Applications]

・ Adjustment of cameras, microscopes and sensors, and optical parts

・ Positioning of production, assembly and inspection processes related to semiconductors and measuring instruments- Volume Discount

Days to Ship: 11 Days or more -

Manual XY-Axis Stages - Cross Roller Guide, Through Hole, B27

Suruga Seiki

A through-hole type cross roller guide (XY-axis) with an integrated XY-axis structure.[Features]・ Lightweight because aluminum is used for the main body material. · The thickness of the body can be reduced compared to a single-axis combination. ・ The diameter of the through-hole is ø50 (diameter: 50 mm), and ø40 (diameter: 40 mm) is maintained even when the stroke is made to XY.

·

[Applications]・ Ideal for fine positioning as a sample inspection table.

・ Ideal for adjusting the dispenser head.

・ Ideal for CCD camera alignment.- Volume Discount

Days to Ship: 8 Days or more -

Manual XY-Axis Stages - Dovetail, Rack and Pinion, XYFG

MISUMI

Square Dovetail Slide XY-Axes Stages with 18mm travel per knob rotation.

- Volume Discount

- inCAD Components

Days to Ship: 10 Days or more -

Manual XY-Axis Stages - Dovetail, Hex Wrench Drive, High Accuracy, XYEEG

MISUMI

This product frees customers from the anxiety of accidental operation and unintended positioning.

- Volume Discount

- Lead Time Reduction

- inCAD Components

Days to Ship: 8 Days or more -

Manual XY-Axis Stages - Linear Ball Guide, High Accuracy, Coarse/Fine Micrometer Heads, XYSKG

MISUMI

Low Temperature Black Chrome Plating Adopted for Surface Treatment. Suitable for Reflection Prevention.

- Volume Discount

- inCAD Components

Days to Ship: 10 Days or more -

Manual XY-Axis Stages - Cross Roller Guide, Thru Hole, XYPPG

MISUMI

Lightweight and High Precision Cross Roller Stages with table through holes made of aluminum alloy.

- Volume Discount

- inCAD Components

Days to Ship: 12 Days or more -

Manual XY-Axis Stages - Cross Roller Guide, High Accuracy, Low Profile, XYSPG

MISUMI

Lightweight and High Precision Cross Roller Stages with low profile made of aluminum alloy.

- Volume Discount

- Lead Time Reduction

- inCAD Components

Days to Ship: 10 Days or more -

Manual Stages - Configurable X/XY/Z-Axis Stages

MISUMI

Selectable kinds of Feed Position, Feed/Clamping Methods and Grease.

Days to Ship: 10 Days or more -

Manual XY-Axis Symmetrical Use Stages - Devetail Groove, Feed Screw, DSXYEG

MISUMI

Symmetrical Stack, XY-axis Stages useable in limited spaces

- Volume Discount

- inCAD Components

Days to Ship: 10 Days or more -

Manual XY-Axis Symmetrical Use Stages - Linear Ball Guide, Feed Screw, Pitch 0.5, DSXYSGB/DSXYSCG

MISUMI

Symmetrical Stack, XY-axis Stages usable in limited spaces

- Volume Discount

- inCAD Components

Days to Ship: 12 Days or more -

Manual XY-Axis Stages - Standard, Dovetail, High Accuracy, Extended Handle, Lead 4.2 mm, XYSC

MISUMI

Dowel holes on top and bottom plates can be used to secure locating repeatability.

- Volume Discount

- inCAD Components

Days to Ship: 8 Days or more -

Manual XY-Axis Stages - Cross Roller Guide, Standard Accuracy, XYCRS

MISUMI

Stage with a micrometer head capable of 0.01mm resolution adjustments.

- Volume Discount

- New Pricing

- inCAD Components

Days to Ship: Same day or more Show Stock Products

-

Manual XY-Axis Stages - Standard Accuracy, Dovetail, XYDTS

MISUMI

Rapid feed rack and pinion stage. More economical than the conventional products.

- Volume Discount

- New Pricing

- inCAD Components

Days to Ship: 8 Days or more -

Manual XY-Axis Stages - Dovetail, Rack and Pinion, Low Profile, Rectangle XYDTSC

MISUMI

XY-axis Rack & Pinion stages with low profile (26mm thick).

- Volume Discount

- New Pricing

- inCAD Components

Days to Ship: 8 Days or more -

MISUMI

The knob shaft is clamped directly to enhance the retaining force.

- Volume Discount

- inCAD Components

Days to Ship: 12 Days or more -

MISUMI

Suitable when feed screws are difficult to turn because the work is larger than the stage surface, or feed screws are hard to reach because the stage is inside of an equipment.

- Volume Discount

- inCAD Components

Days to Ship: 12 Days or more -

Manual XY-Axis Stages - Dovetail, Feed Screw, High Accuracy, 4.2 mm Lead, Rectangle, XYSL

MISUMI

XY-Axis Dovetail Slide Stage with smooth feeding 4.2mm lead.

- Volume Discount

- inCAD Components

Days to Ship: 12 Days or more -

MISUMI

XY-Axis Stage enabling to directly clamp the feed screw shaft with smooth feeding 4.2mm lead and enhanced in retaining force.

- Volume Discount

- inCAD Components

Days to Ship: 12 Days or more -

Manual XY-Axis Stages - Dovetail, High Accuracy, 4.2 mm Lead, Rectangle, Low Profile, XYSLC

MISUMI

For the customers who want a stage unit to become much thinner, the Feed Screw Type - XY-Axis, Low Profile - with smooth 4.2mm lead feed screw!

- Volume Discount

- inCAD Components

Days to Ship: 12 Days or more -

Manual XY-Axis Stages - Dovetail, High Accuracy, Feed Screw, Square, Handle Extension, XYEGL

MISUMI

Feed screw type dovetail stages. The handle can be extended by utilizing the M6 tap.

- Volume Discount

- inCAD Components

Days to Ship: 12 Days or more -

Manual XY-Axis Stages - Dovetail, High Accuracy, Feed Screw - Square, Reinforced Clamp, XYEGCL

MISUMI

XY Dovetail Slide Stage with the position holding performance improved by directly clamping the feed knob shaft. This is suitable for fine feeding of 0.5mm lead.

- Volume Discount

- inCAD Components

Days to Ship: 12 Days or more -

MISUMI

By using Opposed Clamps, the vibration resistance is improved and the greater locking power is ensured without having to use tools!

- Volume Discount

- inCAD Components

Days to Ship: 12 Days or more -

Manual XY-Axis Stages - Dovetail, Feed Screw, XY/XYFES

MISUMI

Feed Screw Stages with 0.5mm fine feed lead.

- Volume Discount

- New Pricing

- inCAD Components

Days to Ship: Same day or more Show Stock Products

-

Manual XY-Axis Stages - Linear Ball Guide, Micrometer Head, XYLBS

MISUMI

Guide-integrated Linear Ball mechanism achieves high load capacity while ensuring accuracy.

- Volume Discount

- Spec Change

- Price Reduction

- inCAD Components

Days to Ship: 8 Days or more -

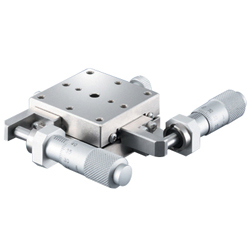

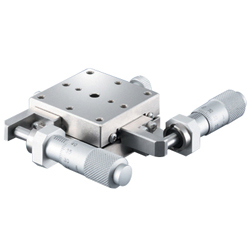

Manual XY-Axis Stages - Linear Ball Guide, Stainless Steel, Electroless Nickel Plating, BSS26

Suruga Seiki

A highly accurate, high rigidity linear ball guide type stage (XY-axis).[Features]・ Achieved high stiffness and high accuracy by adopting stainless steel as the body material and gothic arch grooves in the guide part.

・ The perpendicularity of assembly is within 10 μm.

・ There are 7 stage surface sizes available: 25 × 25 mm, 40 × 40 mm, 50 × 50 mm, 60 × 60 mm, 70 × 70 mm, 80 × 80 mm, and 100 × 100 mm square.

・ The feed position can be selected from the center or the side drive.

・ A wide variety of feeding methods are available.

[Applications]・ Precision adjustment of cameras, microscopes, sensors and optical components

・ Positioning of production, assembly and inspection processes related to semiconductors and measuring instruments- Volume Discount

Days to Ship: 10 Days or more -

Manual XY-Axis Stages - Cross Roller Guide, Low Profile, B23

Suruga Seiki

A low profile cross roller guide stage (XY-axis) with an integrated XY-axis structure.[Features]・ Lightweight as the body material is made of aluminum

・ The thickness of the main body can be reduced compared to the single axis combination.

・ Available in 40 mm, 60 mm, 80 mm, and 100 mm square stage sizes

[Applications]・ Ideal for fine positioning as a sample inspection table.

・ Ideal for adjusting the dispenser head.

・ Ideal for CCD camera alignment.- Volume Discount

Days to Ship: 8 Days or more -

Manual XY-Axis Stages - Linear Ball Guide, Low Profile, Stainless Steel, BSS23

Suruga Seiki

A low profile linear ball guide stage (XY-axis) with an integrated XY-axis structure.[Features]・ Achieved high stiffness and high accuracy by adopting stainless steel as the body material and gothic arch grooves in the guide part.

・ The thickness of the main body can be reduced compared to the single axis combination. ・ Stage sizes available are 40 mm, 50 mm, 60 mm, 70 mm, 80 mm, and 100 mm square

[Applications]・ Ideal for fine positioning as a sample inspection table.

・ Ideal for adjusting the dispenser head.

・ Ideal for CCD camera alignment.- Volume Discount

Days to Ship: 10 Days or more -

Manual XY-Axis Stages - Dovetail, Feed Screw, B08/BDBYR/BDBYS

Suruga Seiki

A feed screw type dovetail stage (XY-axis) with a wide range of sizes and strokes.[Features]・ It is composed of a nut and a feed screw on the main body side, and fine adjustment is possible compared to a rack and a pinion

・ The feed method can be selected from the knob type or the hex key operation type

・ The hex key operation type is space-saving and effective in preventing erroneous operation

[Applications]・ Adjustment of cameras, microscopes, sensors and optical components

・ Positioning of production, assembly and inspection processes related to semiconductors and measuring instruments- Volume Discount

Days to Ship: 8 Days or more -

Suruga Seiki

A linear ball guide stage (XY-axis) that achieves "high stiffness and high accuracy."[Features]・ Achieved high stiffness and high accuracy by adopting stainless steel as the body material and gothic arch grooves in the guide part.

・ The perpendicularity of assembly is within 10 μm.

・ Four types of stage surface sizes are available: 25 × 25 mm, 40 × 40 mm, 60 × 60 mm, and 80 × 80 mm square.

・ The feed position can be selected from the center or the side drive.

・ A wide variety of feeding methods are available.

[Applications]・ Precision adjustment of cameras, microscopes, sensors and optical components

・ Positioning of production, assembly and inspection processes related to semiconductors and measuring instruments- Volume Discount

Days to Ship: 11 Days or more -

Manual XY-Axis Stages - Dovetail, Hex Wrench, Small, Block Stage, TAS

NBK

[Features]

- Move the stage with a hex wrench.

- Screws are used for micro-feeding.

- Dovetail grooves used for the travel guide.

- Has a mechanism for correcting rattling.

- New design with lowered stage height.

- Useful in limited spaces.

- Mounting method: Mounting screw holes are countersunk.

- It can therefore be fixed from either above or below.

- [Fixing from above] TAS-251: M2, TAS-401: M3 [Fixing from below] TAS-251: M3, TAS-401: M4, material and finishing are brass and black chrome plating.- Volume Discount

Days to Ship: 11 Days or more -

Manual XY-Axis Stages - V-Groove Cross Roller Guide, High-Grade Aluminum, 30 x 30 mm

Chuo Precision Industrial

[Features]

•Offers both rigidity and low weight by utilizing aluminum alloy as the main material and an HG-VCR guidance method

•Standard and inverse models available, giving left/right symmetry

•Standard micron and fine pitch micron feeds available

•Wide-ranging applications, for example, positioning of cameras, sensors, and other items- Volume Discount

Days to Ship: 11 Days or more -

Manual XY-Axis Stages - V-Groove Cross Roller Guide, High-Grade Aluminum, 40 x 40 mm

Chuo Precision Industrial

A HG-VCR automatic stage with high precision and rigidity.

- Volume Discount

Days to Ship: 8 Days or more -

Manual XY-Axis Stages - Slim Profile

Chuo Precision Industrial

[Features]

· Thin-type stage using a V-groove and a cross roller (V-CR type) for the travel guide.

· The operating section can be attached at the center, the side, and the opposite side.

· Can be used for a wide range of purposes such as precise positioning of the work and a sampling stage of measurement equipment.- Volume Discount

Days to Ship: 8 Days or more -

Manual XY-Axis Stages - V-Groove Cross Roller, High-Precision

Chuo Precision Industrial

[Features]

High-precision stage using V groove and cross roller (V-CR type) for the travel guide.

Can be used for a wide range of purposes, such as precise positioning of the work and a sampling stage of measurement equipment.

• [LD-241] [LD-243]

The operating section is attached on the center or the side.

Feeding is performed with a standard micrometer or a digital micrometer.

• [LD-242]

Available with a vernier scale or magnescale.- Volume Discount

Days to Ship: 13 Days or more -

Manual XY-Axis Stages - Screw Stage

Chuo Precision Industrial

This is an XYZ-axis fine movement unit.

[Features]

· It is an XY-axis fine movement unit.

· Uses dovetail groove (D-T type) for the travel guide, and feed auger as the feed type.

· Can be widely used for applications requiring the positioning of cameras, sensors, and other items.

· Capable of Securing It with a High Holding Clamp at any Position- Volume Discount

Days to Ship: 11 Days or more -

Manual XY-Axis Stages - Dovetail

Chuo Precision Industrial

A mobile unit with a dovetail groove for the moving guide.

- Volume Discount

Days to Ship: 8 Days or more -

Manual XY-Axis Stages - Fixed Position

Chuo Precision Industrial

Clampless XY-axis fixed stage that stays in place after position adjustment.

[Features]

· Clampless stage that stays in place after position adjustment.

· Special mechanism to prevent backlash.

· Patent obtained.

· Use hex wrench to adjust position.

· Virtually no clamp screws or other projections from the main stage body.

· Can be installed horizontally, vertically or upside-down (load capacity restriction depends on the installation orientation).

[Applications]

· Ideal for workpieces that must remain stationary after camera or sensor position adjustment.- Volume Discount

Days to Ship: 8 Days or more -

Manual XY-Axis Stages - Fixed Position, Low Profile

Chuo Precision Industrial

Has the same fixed stage mechanism as conventional products, with a width as slim as a spacer. No clamping needed, making it good for tight spaces.

- Volume Discount

- CAD :

- 2D

Days to Ship: 8 Days or more

| Brand |

|---|

| Product Series |

| CAD |

| Days to Ship |

| Specifications |

| Travel (X Distance) Range(mm) |

| Travel (Y Distance) Range(mm) |

| Load Capacity (Range)(N) |

| Table Size (Length) L (Range)(mm) |

| Table Size (Width) W (Range)(mm) |

| Table Size (Thickness) H (Range)(mm) |

| Feeding Method |

| Guiding Mechanism |

| Table Material |

| Table Surface Treatment |

|

|

|

|

|

|

|

|

|

|

| |||||||||||||||||||||||||||||||||||

| Brand | MISUMI | MISUMI | MISUMI | MISUMI | MISUMI | MISUMI | Suruga Seiki | Suruga Seiki | Suruga Seiki | MISUMI | MISUMI | MISUMI | MISUMI | MISUMI | MISUMI | MISUMI | MISUMI | MISUMI | MISUMI | MISUMI | MISUMI | MISUMI | MISUMI | MISUMI | MISUMI | MISUMI | MISUMI | MISUMI | MISUMI | MISUMI | MISUMI | Suruga Seiki | Suruga Seiki | Suruga Seiki | Suruga Seiki | Suruga Seiki | NBK | Chuo Precision Industrial | Chuo Precision Industrial | Chuo Precision Industrial | Chuo Precision Industrial | Chuo Precision Industrial | Chuo Precision Industrial | Chuo Precision Industrial | Chuo Precision Industrial |

| Product Series | Manual XY-Axis Stages - Cross Roller Guide, High Accuracy, XYPG/XYPGN/XYPCG | Manual XY-Axis Stages - Rectangular Dovetail, Rack and Pinion, High Accuracy, XYWG | Manual XY-Axis Stages - Linear Ball Guide, High Accuracy, XYSG/XYSGB/XYSCG/XYSCGB | Manual XY-Axis Stages - Linear Ball Guide, Low Profile, High Accuracy, XYSSG/XYSSCG | Manual XY-Axis Stages - Cross Roller Guide, Low Profile, XY/XYCRSC | Manual XY-Axis Stages - Cross Roller Guide, High Accuracy, Lightweight, B21 | Manual XY-Axis Stages - Cross Roller Guide, Through Hole, B27 | Manual XY-Axis Stages - Dovetail, Hex Wrench Drive, High Accuracy, XYEEG | Manual XY-Axis Stages - Linear Ball Guide, High Accuracy, Coarse/Fine Micrometer Heads, XYSKG | Manual XY-Axis Stages - Cross Roller Guide, Thru Hole, XYPPG | Manual XY-Axis Stages - Cross Roller Guide, High Accuracy, Low Profile, XYSPG | Manual XY-Axis Symmetrical Use Stages - Devetail Groove, Feed Screw, DSXYEG | Manual XY-Axis Symmetrical Use Stages - Linear Ball Guide, Feed Screw, Pitch 0.5, DSXYSGB/DSXYSCG | Manual XY-Axis Stages - Standard, Dovetail, High Accuracy, Extended Handle, Lead 4.2 mm, XYSC | Manual XY-Axis Stages - Cross Roller Guide, Standard Accuracy, XYCRS | Manual XY-Axis Stages - Dovetail, Rack and Pinion, Low Profile, Rectangle XYDTSC | Manual XY-Axis Stages - Dovetail, Feed Screw, High Accuracy, 4.2 mm Lead, Rectangle, XYSL | Manual XY-Axis Stages - Dovetail, High Accuracy, 4.2 mm Lead, Rectangle, Low Profile, XYSLC | Manual XY-Axis Stages - Dovetail, High Accuracy, Feed Screw, Square, Handle Extension, XYEGL | Manual XY-Axis Stages - Dovetail, High Accuracy, Feed Screw - Square, Reinforced Clamp, XYEGCL | Manual XY-Axis Stages - Linear Ball Guide, Micrometer Head, XYLBS | Manual XY-Axis Stages - Linear Ball Guide, Stainless Steel, Electroless Nickel Plating, BSS26 | Manual XY-Axis Stages - Cross Roller Guide, Low Profile, B23 | Manual XY-Axis Stages - Linear Ball Guide, Low Profile, Stainless Steel, BSS23 | Manual XY-Axis Stages - Dovetail, Feed Screw, B08/BDBYR/BDBYS | Manual XY-Axis Stages - Dovetail, Hex Wrench, Small, Block Stage, TAS | Manual XY-Axis Stages - V-Groove Cross Roller Guide, High-Grade Aluminum, 30 x 30 mm | Manual XY-Axis Stages - V-Groove Cross Roller Guide, High-Grade Aluminum, 40 x 40 mm | Manual XY-Axis Stages - V-Groove Cross Roller, High-Precision | ||||||||||||||||

| CAD |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| Days to Ship | 10 Days or more | 8 Days or more | 8 Days or more | 8 Days or more | 10 Days or more | 8 Days or more | 8 Days or more | 11 Days or more | 8 Days or more | 10 Days or more | 8 Days or more | 10 Days or more | 12 Days or more | 10 Days or more | 10 Days or more | 10 Days or more | 12 Days or more | 8 Days or more |

Same day or more

Show Stock Products | 8 Days or more | 8 Days or more | 12 Days or more | 12 Days or more | 12 Days or more | 12 Days or more | 12 Days or more | 12 Days or more | 12 Days or more | 12 Days or more |

Same day or more

Show Stock Products | 8 Days or more | 10 Days or more | 8 Days or more | 10 Days or more | 8 Days or more | 11 Days or more | 11 Days or more | 11 Days or more | 8 Days or more | 8 Days or more | 13 Days or more | 11 Days or more | 8 Days or more | 8 Days or more | 8 Days or more |

| Specifications |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||||||||||||||||||

| Travel (X Distance) Range(mm) | Up to ±10mm / ±10 to 30mm | Up to ±10mm | ±10 to 30mm / ±30mm or More | Up to ±10mm / ±10 to 30mm | Up to ±10mm / ±10 to 30mm | Up to ±10mm / ±10 to 30mm | Up to ±10mm / ±10 to 30mm | Up to ±10mm / ±10 to 30mm | Up to ±10mm / ±10 to 30mm | Up to ±10mm / ±10 to 30mm | Up to ±10mm | Up to ±10mm | ±10 to 30mm | Up to ±10mm / ±10 to 30mm | Up to ±10mm / ±10 to 30mm | Up to ±10mm | Up to ±10mm / ±10 to 30mm | ±10 to 30mm | Up to ±10mm / ±10 to 30mm | ±10 to 30mm / ±30mm or More | ±10 to 30mm / ±30mm or More | ±10 to 30mm / ±30mm or More | ±10 to 30mm | ±10 to 30mm / ±30mm or More | ±10 to 30mm / ±30mm or More | ±10 to 30mm / ±30mm or More | Up to ±10mm | Up to ±10mm | Up to ±10mm | Up to ±10mm | Up to ±10mm | Up to ±10mm / ±10 to 30mm | Up to ±10mm / ±10 to 30mm | Up to ±10mm / ±10 to 30mm | Up to ±10mm | Up to ±10mm / ±10 to 30mm | Up to ±10mm | - | - | - | - | - | - | - | - |

| Travel (Y Distance) Range(mm) | Up to ±10mm / ±10 to 30mm | Up to ±10mm | ±10 to 30mm / ±30mm or More | Up to ±10mm / ±10 to 30mm | Up to ±10mm / ±10 to 30mm | Up to ±10mm / ±10 to 30mm | Up to ±10mm / ±10 to 30mm | Up to ±10mm / ±10 to 30mm | Up to ±10mm / ±10 to 30mm | Up to ±10mm / ±10 to 30mm | Up to ±10mm | Up to ±10mm | ±10 to 30mm | Up to ±10mm / ±10 to 30mm | Up to ±10mm / ±10 to 30mm | Up to ±10mm | Up to ±10mm / ±10 to 30mm | ±10 to 30mm | Up to ±10mm / ±10 to 30mm | ±10 to 30mm / ±30mm or More | ±10 to 30mm / ±30mm or More | ±10 to 30mm / ±30mm or More | ±10 to 30mm | ±10 to 30mm / ±30mm or More | ±10 to 30mm / ±30mm or More | ±10 to 30mm / ±30mm or More | Up to ±10mm | Up to ±10mm | Up to ±10mm | Up to ±10mm | Up to ±10mm | Up to ±10mm / ±10 to 30mm | Up to ±10mm / ±10 to 30mm | Up to ±10mm / ±10 to 30mm | Up to ±10mm | Up to ±10mm / ±10 to 30mm | Up to ±10mm | - | - | - | - | - | - | - | - |

| Load Capacity (Range)(N) | 5 to 30 / 30.1 to 50 / 50.1 to 100 / 100.1 or More | 5 to 30 / 30.1 to 50 | 5 to 30 / 30.1 to 50 | 30.1 to 50 / 50.1 to 100 / 100.1 or More | 50.1 to 100 / 100.1 or More | 5 to 30 / 30.1 to 50 / 100.1 or More | 5 to 30 / 30.1 to 50 / 50.1 to 100 / 100.1 or More | 5 to 30 | 50.1 to 100 | 5 to 30 | 5 to 30 / 30.1 to 50 | 50.1 to 100 / 100.1 or More | 50.1 to 100 | 5 to 30 / 30.1 to 50 | 5 to 30 / 30.1 to 50 / 50.1 to 100 / 100.1 or More | 5 to 30 / 30.1 to 50 | 30.1 to 50 / 50.1 to 100 / 100.1 or More | 5 to 30 | 5 to 30 / 30.1 to 50 / 50.1 to 100 / 100.1 or More | 5 to 30 / 30.1 to 50 | 5 to 30 | 5 to 30 / 30.1 to 50 | 5 to 30 | 30.1 to 50 | 30.1 to 50 | 5 to 30 | 5 to 30 / 30.1 to 50 | 5 to 30 / 30.1 to 50 | 30.1 to 50 / 50.1 to 100 / 100.1 or More | 5 to 30 / 30.1 to 50 | 50.1 to 100 / 100.1 or More | 30.1 to 50 / 50.1 to 100 / 100.1 or More | 5 to 30 / 30.1 to 50 | 50.1 to 100 / 100.1 or More | 5 to 30 / 30.1 to 50 | 30.1 to 50 / 50.1 to 100 / 100.1 or More | 5 to 30 / 30.1 to 50 | 5 to 30 | 50.1 to 100 / 100.1 or More | 50.1 to 100 / 100.1 or More | 100.1 or More | 5 to 30 | 1 to 4.9 / 30.1 to 50 | 1 to 4.9 / 30.1 to 50 / 50.1 to 100 | 5 to 30 |

| Table Size (Length) L (Range)(mm) | Up to 25 ~ 91 to 120 | Up to 25 ~ 41 to 60 | 41 to 60 ~ 121 or More | Up to 25 ~ 91 to 120 | 26 to 40 ~ 91 to 120 | Up to 25 ~ 91 to 120 | Up to 25 ~ 91 to 120 | Up to 25 ~ 41 to 60 | 91 to 120 | Up to 25 ~ 41 to 60 | Up to 25 ~ 41 to 60 | 26 to 40 ~ 61 to 90 | 91 to 120 | 26 to 40 ~ 91 to 120 | Up to 25 ~ 61 to 90 | Up to 25 ~ 41 to 60 | Up to 25 ~ 91 to 120 | 26 to 40 ~ 41 to 60 | Up to 25 ~ 91 to 120 | 41 to 60 ~ 61 to 90 | 41 to 60 ~ 61 to 90 | 41 to 60 ~ 61 to 90 | 26 to 40 ~ 41 to 60 | 41 to 60 ~ 61 to 90 | 41 to 60 ~ 61 to 90 | 41 to 60 ~ 61 to 90 | Up to 25 ~ 41 to 60 | Up to 25 ~ 41 to 60 | Up to 25 ~ 61 to 90 | Up to 25 ~ 41 to 60 | 26 to 40 ~ 41 to 60 | Up to 25 ~ 91 to 120 | 26 to 40 ~ 91 to 120 | 26 to 40 ~ 91 to 120 | Up to 25 ~ 41 to 60 | Up to 25 ~ 61 to 90 | Up to 25 ~ 26 to 40 | 26 to 40 | 26 to 40 ~ 61 to 90 | 61 to 90 ~ 121 or More | 121 or More | 26 to 40 ~ 41 to 60 | 26 to 40 | Up to 25 ~ 41 to 60 | 26 to 40 ~ 41 to 60 |

| Table Size (Width) W (Range)(mm) | Up to 25 ~ 91 to 120 | Up to 25 ~ 41 to 60 | Up to 25 ~ 26 to 40 | Up to 25 ~ 91 to 120 | 26 to 40 ~ 91 to 120 | Up to 25 ~ 91 to 120 | Up to 25 ~ 91 to 120 | Up to 25 ~ 41 to 60 | 91 to 120 | Up to 25 ~ 41 to 60 | Up to 25 ~ 41 to 60 | 26 to 40 ~ 61 to 90 | 91 to 120 | 26 to 40 ~ 91 to 120 | Up to 25 ~ 61 to 90 | Up to 25 ~ 41 to 60 | Up to 25 ~ 91 to 120 | 26 to 40 ~ 41 to 60 | Up to 25 ~ 91 to 120 | 26 to 40 | 26 to 40 | Up to 25 ~ 26 to 40 | 26 to 40 ~ 41 to 60 | 26 to 40 | 26 to 40 | 26 to 40 | Up to 25 ~ 41 to 60 | Up to 25 ~ 41 to 60 | Up to 25 ~ 61 to 90 | Up to 25 ~ 41 to 60 | 26 to 40 ~ 41 to 60 | Up to 25 ~ 91 to 120 | 26 to 40 ~ 91 to 120 | 26 to 40 ~ 91 to 120 | Up to 25 ~ 41 to 60 | Up to 25 ~ 61 to 90 | Up to 25 ~ 26 to 40 | 26 to 40 | 26 to 40 ~ 61 to 90 | 61 to 90 ~ 121 or More | 121 or More | Up to 25 | 26 to 40 ~ 121 or More | Up to 25 ~ 41 to 60 | 26 to 40 ~ 41 to 60 |

| Table Size (Thickness) H (Range)(mm) | 25.1 to 30 ~ 50.1 to 60 | 25.1 to 30 ~ 30.1 to 35 | 50.1 to 60 ~ 60.1 to 70 | 20.1 to 25 ~ 35.1 to 40 | 20.1 to 25 ~ 25.1 to 30 | 1 to 15 ~ 35.1 to 40 | 25.1 to 30 ~ 50.1 to 60 | 35.1 to 40 ~ 70.1 to 80 | 25.1 to 30 | 35.1 to 40 ~ 70.1 to 80 | 25.1 to 30 ~ 40.1 to 50 | 30.1 to 35 ~ 35.1 to 40 | 25.1 to 30 | 20.1 to 25 ~ 25.1 to 30 | 1 to 15 ~ 35.1 to 40 | 25.1 to 30 ~ 30.1 to 35 | 20.1 to 25 ~ 35.1 to 40 | 35.1 to 40 | 25.1 to 30 ~ 35.1 to 40 | 60.1 to 70 | 40.1 to 50 | 60.1 to 70 | 35.1 to 40 | 50.1 to 60 | 50.1 to 60 | 40.1 to 50 | 25.1 to 30 ~ 30.1 to 35 | 25.1 to 30 ~ 30.1 to 35 | 20.1 to 25 ~ 35.1 to 40 | 25.1 to 30 ~ 30.1 to 35 | 35.1 to 40 | 20.1 to 25 ~ 35.1 to 40 | 20.1 to 25 ~ 25.1 to 30 | 20.1 to 25 ~ 25.1 to 30 | 25.1 to 30 ~ 50.1 to 60 | 20.1 to 25 ~ 35.1 to 40 | 25.1 to 30 | - | - | - | - | - | - | - | - |

| Feeding Method | Feed Screw | Feed Screw | Rack & Pinion | Feed Screw | Feed Screw | - | Feed Screw / Micrometer Heads | - | - | Rack & Pinion | Feed Screw | - | - | - | - | Feed Screw | Feed Screw | Feed Screw | - | Rack & Pinion | Rack & Pinion | Rack & Pinion | Feed Screw | Feed Screw | Feed Screw | Feed Screw | Feed Screw | Feed Screw | - | Feed Screw | - | Feed Screw / Micrometer Heads | - | - | - | Feed Screw / Micrometer Heads | - | Micrometer Heads | Feed Screw / Micrometer Heads | Micrometer Heads | Micrometer Heads | Feed Screw | Rack & Pinion | Feed Screw | Feed Screw |

| Guiding Mechanism | Cross Roller | Dovetail Slide | Dovetail Slide | Linear Ball | Linear Ball | Cross Roller | Cross Roller | Dovetail Slide | Cross Roller | Dovetail Slide | Dovetail Slide | Linear Ball | Cross Roller | Cross Roller | Cross Roller / Linear Ball | Dovetail Slide | Linear Ball | Dovetail Slide | Cross Roller | Dovetail Slide | Dovetail Slide | Dovetail Slide | Dovetail Slide | Dovetail Slide | Dovetail Slide | Dovetail Slide | Dovetail Slide | Dovetail Slide | Linear Ball | Dovetail Slide | Linear Ball | Linear Ball | Cross Roller | Linear Ball | Dovetail Slide | Linear Ball | Dovetail, Feed Screw | Cross Roller | Cross Roller | Cross Roller | Cross Roller | Dovetail Slide | Dovetail Slide | Slide Guide | Slide Guide |

| Table Material | Aluminum Alloy | Brass | Aluminum Alloy | Stainless Steel | Stainless Steel | Aluminum Alloy | Aluminum | Aluminum / Brass | Aluminum | Brass / Aluminum Alloy | Brass | Stainless Steel | Aluminum Alloy | Aluminum Alloy | Stainless Steel / Aluminum Alloy | Brass | Stainless Steel | Aluminum Alloy | Aluminum Alloy | Aluminum Alloy | Aluminum Alloy | Aluminum Alloy | Aluminum Alloy | Aluminum Alloy | Aluminum Alloy | Aluminum Alloy | Brass | Brass | Stainless Steel | Aluminum Alloy | Stainless Steel | Stainless Steel | Aluminum | Stainless Steel | Aluminum / Brass | Stainless Steel | Brass | Aluminum Alloy | Stainless Steel | Steel / Aluminum Alloy | Steel | Brass | Aluminum Alloy | Aluminum Alloy | Aluminum Alloy |

| Table Surface Treatment | Black Anodize | - | Black Anodize | Electroless Nickel / Low Temperature Black Chrome | Electroless Nickel | Black Anodize | Black Anodize | Black Anodize / Black Oxide | Black Anodize | Black Anodize | - | Electroless Nickel | Black Anodize | Black Anodize | Black Anodize / Electroless Nickel | - | Electroless Nickel / Low Temperature Black Chrome | Black Anodize | Black Anodize | Black Anodize | Black Anodize | Black Anodize | Black Anodize | Black Anodize | Black Anodize | Black Anodize | - | - | Electroless Nickel | Black Anodize | Electroless Nickel | Electroless Nickel | Black Anodize | Electroless Nickel | Black Anodize / Black Oxide | Low Temperature Black Chrome | Low Temperature Black Chrome | Black Anodize | Low Temperature Black Chrome | Black Anodize / Low Temperature Black Chrome | Low Temperature Black Chrome | Low Temperature Black Chrome | Black Anodize | None / Black Anodize | Black Anodize |

Loading...

Configure

Stock

-

- Show Stock Products

Specification/Dimensions

-

Metric / Inch

-

Travel (X Distance) Range(mm)

-

Travel (Y Distance) Range(mm)

-

Load Capacity (Range)(N)

-

Table Size (Length) L (Range)(mm)

-

Table Size (Width) W (Range)(mm)

-

Table Size (Thickness) H (Range)(mm)

The height is from the bottom to the top of the mounting surface. The micrometer head is not counted for the measurement.

-

Feeding Method

-

Guiding Mechanism

-

Table Material

-

Table Surface Treatment

Narrow search by specifying Manufacturer

CAD

-

- 2D

- 3D

Related Categories to Manual XY-Axis Stages

-

- Base Plates for Manual Stages

- Brackets for Manual Stages

- Manual Goniometer Stages

- Manual Multi-Axis Stages

- Manual Rotary Stages

- Manual Tilt Stages

- Manual X-Axis Stages

- Manual XY-Axis Stages

- Manual XYZ-Axis Stages

- Manual XZ-Axis Stages

- Manual Z-Axis Stages

- Micrometer Heads & Feed Screws

- Mounting Accessories for CCD Cameras

- Positioning Stage Suction Plates

- Rods, Mounts & Cross Clamps

- Scales for Manual Stages

-

How can we improve?

How can we improve?

While we are not able to respond directly to comments submitted in this form, the information will be reviewed for future improvement.

Customer Privacy Policy

Thank you for your cooperation.

While we are not able to respond directly to comments submitted in this form, the information will be reviewed for future improvement.

Please use the inquiry form.

Customer Privacy Policy