(!)Due to Microsoft's end of support for Internet Explorer 11 on 15/06/2022, this site does not support the recommended environment.

Our Business Hours:

Mon. - Fri. 8 a.m. - 6 p.m.

Mon. - Fri. 8 a.m. - 6 p.m.

All Categories

Categories

- Automation Components

- Linear Motion

- Rotary Motion

- Connecting Parts

- Rotary Power Transmission

- Motors

- Conveyors & Material Handling

- Locating, Positioning, Jigs & Fixtures

- Inspection

- Sensors, Switches

- Pneumatics, Hydraulics

- Vacuum Components

- Hydraulic Equipment

- Spray Equipment And Accessories

- Pipe, Tubes, Hoses & Fittings

- Modules, Units

- Heaters, Temperature Control

- Aluminum Extrusions, Framing, Support & Posts

- Casters, Leveling Mounts, Posts

- Doors, Cabinet Hardware

- Springs, Shock Absorbers

- Adjustment/Fastening Components, Pins, Magnets

- Antivibration, Soundproofing Materials, Safety Products

- Fasteners

- Materials

- Wiring Components

- LAN Cables / Industrial Network Cables

- Equipment Specific Cables

- Cordsets

- Computer & AV Cables

- Wire/Cable

- Connector (General Purpose)

- Crimp Terminal Components

- Cable Organization

- Cable Gland Components

- Cable Bushing/Clip/Sticker

- Screw/Spacer

- Cable accessories

- Tube

- Electrical Conduits

- Duct/Wiring

- Electrical Wiring Tools

- Dedicated tools

- Soldering supplies

- Electrical & Controls

- Cutting Tools

- Carbide End Mill

- HSS End Mill

- Concrete Drill Bits

- Milling Cutter Insert / Holder

- Core Drill Bits

- Customized Straight Blade End Mill

- Dedicated Cutter

- Crinkey Cutters

- Turning Tool

- Drill

- Cutting Tool Accessories

- Screw Hole Related Tools

- Reamer

- Electric Drill Bits

- Chamfering, Centering Tool

- Hole Saws

- Magnetic Drill Press Cutters

- Step Drills

- Wood Drills & Cutters

- Processing Tools

- packing & logistics storage supplies

- Safety Products

- research and development & cleanroom supplies

- Press Die Components

- Plastic Mold Components

- Ejector Pins

- Sleeves, Center Pins

- Core Pins

- Sprue bushings, Gates, and other components

- Date Mark Inserts, Recycle Mark Inserts, Pins with Gas Vent

- Undercut, Plates

- Leader Components, Components for Ejector Space

- Mold Opening Controllers

- Cooling or Heating Components

- Accessories, Others

- Components of Large Mold, Die Casting

- Injection Molding Components

- Purging Agent

- Injection Molding Machine Products

- Accessories of Equipment

- Auxiliary Equipment

- Air Nippers

- Air Cylinders

- Air Chuck for Runner

- Chuck Board Components

- Frames

- Suction Components

- Parallel Air Chuck

- Special Air Chuck

- Mold Maintenance

- Heating Items

- Heat Insulation Sheets

- Couplers, Plugs, One-touch Joints

- Tubes, Hoses, Peripheral Components

Applications

Brands

- Webcode Seach | Series

-

#CODE

- Discontinued Products

- Scheduled Maintenance Notice: This site will be unavailable due to scheduled maintenance from 7:00 p.m. 11/23/2024 to 5:00 p.m. (CST) 11/24/2024. We apologize for the inconvenience.

Linear Ball Bushings - Linear/Rotating, flanged. (Part Numbers)

- Volume Discount

•TYPE: Flange

•Motion: Linear/Rotary

•Style: Standard

•Outer Cylinder Material: 52100 Bearing Steel Equivalent

•Flange Type: Standard Flange

- METRIC

- inCAD Components

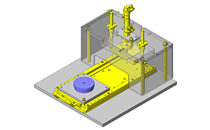

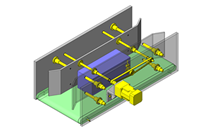

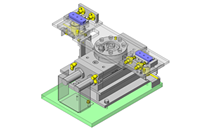

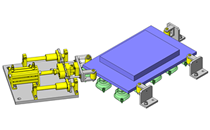

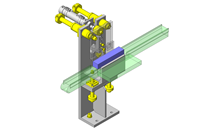

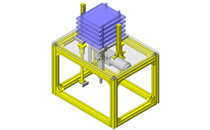

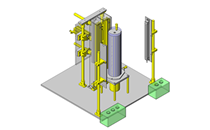

Unit examples related to this product

Part Number

Configured Part Number is shown.

・Materials

| Type | Type | Outer Cylinder | Balls | Retainer | Ambient Operating Temp. | |||

| Round Flange | Square Flange | Compact Flange | [ M ]Material | [ H ]Hardness | [ M ]Material | [ M ]Material | ||

| Single | LBHR | LBHS | LBHC | 52100 Bearing Steel | 58HRC~ | 52100 Bearing Steel | 5052 Aluminum Alloy | -20~110°C |

| Double | LBHRW | LBHSW | LBHCW | |||||

*Retaining Ring

[ M ] Material: 301 Stainless Steel

[ M ] Material: 301 Stainless Steel

Specifications

| Part Number |

| LBHR10 |

| dr | Maximum Stroke | Number of Ball Rows | ℓ1 | D | L | H | T | d | d1 | t | P.C.D. | W | F | A | Eccentricity | *Perpendicularity | Basic Load Rating | Allowable Static Moment (N·m) | ||||||||||

| C (Dynamic) N | Co (Static) N | |||||||||||||||||||||||||||

| Tolerance | Single | Double | Single | Double | Single | Double | Tolerance | Tolerance | Single | Double | Single | Double | Single | Double | ||||||||||||||

| 6 | 0 -0.009 | 15 | 7 | 3 | 6 | 8.3 | 12.3 | 12 | 0 | 19 | ±0.3 | 28 | 5 | 3.5 | 6 | 3.1 | 20 | 22 | - | 20 | 0.012 | 0.012 | 210 | 333 | 164 | 328 | - | 2.18 |

| 8 | 24 | 8 | 8.8 | 16.8 | 15 | -0.013 | 24 | 32 | 24 | 25 | - | 24 | 323 | 512 | 278 | 556 | - | 4.31 | ||||||||||

| 10 | 30 | 8 | 10.8 | 21.8 | 19 | 29 | 40 | 6 | 4.5 | 7.5 | 4.1 | 29 | 30 | - | 29 | 499 | 793 | 408 | 815 | - | 7.24 | |||||||

| 12 | 32 | 8 | 10.4 | 22.4 | 21 | 0 | 30 | 42 | 32 | 32 | - | 32 | 722 | 1146 | 579 | 1157 | - | 10.9 | ||||||||||

| 13 | 34 | 10 | 11.4 | 23.4 | 23 | -0.016 | 32 | 43 | 33 | 34 | - | 33 | 773 | 1226 | 634 | 1268 | - | 11.6 | ||||||||||

| 16 | 40 | 16 | 12.8 | 24.8 | 28 | 37 | 48 | 38 | 37 | 22 | 31 | 1330 | 2112 | 1029 | 2058 | - | 19.7 | |||||||||||

| 20 | 0 | 46 | 28 | 14.8 | 23.8 | 32 | 0 | 42 | 54 | 8 | 5.5 | 9 | 5.1 | 43 | 42 | 24 | 36 | 0.015 | 0.015 | 1609 | 2554 | 1517 | 3035 | - | 26.8 | |||

| -0.010 | -0.019 | |||||||||||||||||||||||||||

kgf=Nx0.101972

[ ! ]For Precautions for Use, see >> Click here

■Single

| Part Number | Mass (g) | |||

| Type | dr | Round | Square | Compact |

| LBHR LBHS LBHC | 6 | 23 | 17 | 20 |

| 8 | 41 | 33 | 37 | |

| 10 | 71 | 51 | 63 | |

| 12 | 67 | 48 | 59 | |

| 13 | 87 | 71 | 80 | |

| 16 | 119 | 103 | 111 | |

| 20 | 176 | 141 | 163 | |

■Double

| Part Number | Mass (g) | |||

| Type | dr | Round | Square | Compact |

| LBHRW LBHSW LBHCW | 6 | 24 | 18 | 21 |

| 8 | 43 | 35 | 39 | |

| 10 | 74 | 54 | 66 | |

| 12 | 71 | 52 | 63 | |

| 13 | 91 | 75 | 84 | |

| 16 | 126 | 110 | 118 | |

| 20 | 184 | 149 | 171 | |

Price list

■Volume Discount Rate ([ ! ]Round down to nearest one cent.) P.89

· LBUS, LBUW

[ ! ]For orders larger than indicated quantity, please request a quotation.

· Others

[ ! ]For orders larger than indicated quantity, please request a quotation.

· LBUS, LBUW

| Quantity | 1~19 | 20~34 | 35~49 | 50~99 |

| Discount Rate | Unit Price | 5% | 10% | 18% |

| Days to Ship | Standard | To Be Quoted | ||

· Others

| Quantity | 1~19 | 20~34 | 35~49 | 50~99 |

| Discount Rate | Unit Price | 5% | 10% | 18% |

| Days to Ship | Standard | To Be Quoted | ||

Part Number

CAD Data download and 3D preview are not available because the part number has not yet been determined.

- *In order to open the CAD Data download and 3D preview screen, the part number must be fixed.

- Please confirm the part number from "Specification / Dimension"on the left side, and then perform the CAD Data Download / 3D Preview operation.

Loading...

| Part Number |

|---|

| LBHS6 |

| LBHS8 |

| LBHS10 |

| LBHS12 |

| LBHS13 |

| LBHS16 |

| LBHS20 |

| LBHSW6 |

| LBHSW8 |

| LBHSW10 |

| LBHSW12 |

| LBHSW13 |

| LBHSW16 |

| LBHSW20 |

Loading...

More Information

■Product Specifications

· Motion mechanism utilizing rolling balls, capable of linear and rotary motion.

· The bearing balls and the rolling surface are in point contact relationship enabling low friction rolling motion.

· Compatible with linear bushings, and load is evenly distributed.

· O.D. tolerance g6 shafts (>> Click here~189) can be used with the linear ball bushings. When using preload, O.D. tolerance h5 shafts are recommended.

■Precautions for Use

· Since the balls do not recirculate, its stroke capability is limited.

· Motion mechanism utilizing rolling balls, capable of linear and rotary motion.

· The bearing balls and the rolling surface are in point contact relationship enabling low friction rolling motion.

· Compatible with linear bushings, and load is evenly distributed.

· O.D. tolerance g6 shafts (>> Click here~189) can be used with the linear ball bushings. When using preload, O.D. tolerance h5 shafts are recommended.

■Precautions for Use

· Since the balls do not recirculate, its stroke capability is limited.

Support Information

Reference: Tolerance Range of Linear Bushing and Shafts made by MISUMI

For MISUMI Linear Bushing, it is recommended to use the combination with MISUMI Shafts (hardened to g6 tolerance).

| H6 | H7 | H8 | H9 | Applicable Part | Functional Classification | Application Example | ||||

|---|---|---|---|---|---|---|---|---|---|---|

| Can be Moved Relatively | Clearance Fit | Roll Fit | f6 | f7 | f7 f8 | Fitted to provide adequate clearance to permit movement (high quality fit). Regular normal temperature bearing lubricated with grease or oil. | Regular Fitting (Often comes apart.) | Part into which a cooled exhaust valve box is inserted. Regular Shaft and Bushing Link lever and bushing | ||

| Fine Roll Fit | g5 | g6 | Continuously revolving part of a precision machine under a light load. Fitting with a narrow gap so as to permit movement (spigot and positioning). Precision sliding part. | Part required for precise motion with virtually no backlash. | Link Device Pin and Lever Key and its groove Precision control valve rod | |||||

| Cannot be Moved Relatively | Transition Fit | Sliding Fit | h5 | h6 | h7 h8 | h9 | Fitting so as to permit movement by hand, with a lubricant applied (high-quality positioning). Special High Precision Sliding Part Unimportant Stationary Part | Can be disassembled and reassembled without damaging components. | Force cannot be transmitted by the fitting force alone. | Fitting a rim and a boss together Fitting the gear of a precision gear device |

| Push Fit | h5 h6 | js6 | Fitting that accommodates a slight gap. Precision fitting that locks both parts during use. Fitting that allows assembly and disassembly with a wooden or lead hammer. | Fitting Coupling Flanges Together Governor Path and Pin Fitting a Gear Rim and a Boss Together | ||||||

Compatible Models

Basic Information

| TYPE | Flange | Motion | Linear/Rotary | Style | Standard |

|---|---|---|---|---|---|

| Outer Cylinder Material | 52100 Bearing Steel Equivalent | Flange Shape | Square Flanged |

- The specifications and dimensions of some parts may not be fully covered. For exact details, refer to manufacturer catalogs .

Additional Products in this Category

- Linear Ball Bushings - With central pilot flange, double.

- Linear Ball Bushings - Bearing Type, Wide Block, Long/Extra Long.

- Linear Ball Bushings - Center flange, double compact, reamed mounting holes.

- Linear Ball Bushings - Flanged, single (Inches).

- Linear Ball Bushings - Single. LM-MG Series (Stainless Steel).

- Linear Ball Bushings - With round flange, single. LMF Series.

- Linear Ball Bushings - With pilot flange, double. LMI/LMI-L Series.

- Linear Ball Bushings - Wide Block Bearing Type, Super (Inches). SPB Series.

Complementary Products

Tech Support

- Technical Support

- Tel:+52-442-672-7661 ext. 2 then wait and dial 4

E-mail: soportetecnico@misumimex.com - Mon. - Fri. 8 a.m. - 6 p.m.

- Technical Inquiry

How can we improve?

How can we improve?

While we are not able to respond directly to comments submitted in this form, the information will be reviewed for future improvement.

Customer Privacy Policy

Thank you for your cooperation.

While we are not able to respond directly to comments submitted in this form, the information will be reviewed for future improvement.

Please use the inquiry form.

Customer Privacy Policy