(!)Due to Microsoft's end of support for Internet Explorer 11 on 15/06/2022, this site does not support the recommended environment.

Mon. - Fri. 8 a.m. - 6 p.m.

All Categories

Categories

- Automation Components

- Linear Motion

- Rotary Motion

- Connecting Parts

- Rotary Power Transmission

- Motors

- Conveyors & Material Handling

- Locating, Positioning, Jigs & Fixtures

- Inspection

- Sensors, Switches

- Pneumatics, Hydraulics

- Vacuum Components

- Hydraulic Equipment

- Spray Equipment And Accessories

- Pipe, Tubes, Hoses & Fittings

- Modules, Units

- Heaters, Temperature Control

- Aluminum Extrusions, Framing, Support & Posts

- Casters, Leveling Mounts, Posts

- Doors, Cabinet Hardware

- Springs, Shock Absorbers

- Adjustment/Fastening Components, Pins, Magnets

- Antivibration, Soundproofing Materials, Safety Products

- Fasteners

- Materials

- Wiring Components

- LAN Cables / Industrial Network Cables

- Equipment Specific Cables

- Cordsets

- Computer & AV Cables

- Wire/Cable

- Connector (General Purpose)

- Crimp Terminal Components

- Cable Organization

- Cable Gland Components

- Cable Bushing/Clip/Sticker

- Screw/Spacer

- Cable accessories

- Tube

- Electrical Conduits

- Duct/Wiring

- Electrical Wiring Tools

- Dedicated tools

- Soldering supplies

- Electrical & Controls

- Cutting Tools

- Carbide End Mill

- HSS End Mill

- Concrete Drill Bits

- Milling Cutter Insert / Holder

- Core Drill Bits

- Customized Straight Blade End Mill

- Dedicated Cutter

- Crinkey Cutters

- Turning Tool

- Drill

- Cutting Tool Accessories

- Screw Hole Related Tools

- Reamer

- Electric Drill Bits

- Chamfering, Centering Tool

- Hole Saws

- Magnetic Drill Press Cutters

- Step Drills

- Wood Drills & Cutters

- Processing Tools

- packing & logistics storage supplies

- Safety Products

- research and development & cleanroom supplies

- Press Die Components

- Plastic Mold Components

- Ejector Pins

- Sleeves, Center Pins

- Core Pins

- Sprue bushings, Gates, and other components

- Date Mark Inserts, Recycle Mark Inserts, Pins with Gas Vent

- Undercut, Plates

- Leader Components, Components for Ejector Space

- Mold Opening Controllers

- Cooling or Heating Components

- Accessories, Others

- Components of Large Mold, Die Casting

- Injection Molding Components

- Purging Agent

- Injection Molding Machine Products

- Accessories of Equipment

- Auxiliary Equipment

- Air Nippers

- Air Cylinders

- Air Chuck for Runner

- Chuck Board Components

- Frames

- Suction Components

- Parallel Air Chuck

- Special Air Chuck

- Mold Maintenance

- Heating Items

- Heat Insulation Sheets

- Couplers, Plugs, One-touch Joints

- Tubes, Hoses, Peripheral Components

Applications

Brands

- Webcode Seach | Series

-

#CODE

- Discontinued Products

Casters - Threaded, with swivel plate, CLTUN series. (CLTUNS65B-R)

- Volume Discount

Light Load Screw in Caster

For complete product overview and details on Casters - Low Load, Swivel, Screw-in, Optional Brake see the sections below:

- inCAD Components

Part Number

Configured Part Number is shown.

CLTUNS65B-R

| Main Body | Wheel | Bearing | ||

| [ M ]Material | [ S ]Surface Treatment | [ M ]Material (Color) | Swiveling Part | Wheel |

| Low Carbon Steel | Trivalent Chromate | Rubber (Black) | Incorporated | None |

Specifications

| Part Number | - | Wheel Material |

| CLTUN65A | - | R |

| Type | Part Number | Wheel Material | H | M | ℓ | r | B | E | Allowable Load (N) | Mass (g) | |

| Type | D | ||||||||||

| Screw-In Type | CLTUN | 40 | R (Rubber) | 59 | 12x1.25 | 14 | 41 | 17 | 21 | 250 | 150 |

| 50 | 68 | 47 | 20 | 22 | 300 | 170 | |||||

| 65A | 85 | 12x1.75 | 35 | 56 | 21 | 23 | 231 | ||||

| 65B | 12x1.25 | 14 | |||||||||

| 75A | 95 | 12x1.75 | 35 | 65 | 27 | 400 | 295 | ||||

| 75B | 12x1.25 | 14 | |||||||||

| With Screw-In Brake Type | CLTUNS | 40 | 59 | 12x1.25 | 14 | 50 | 17 | 21 | 250 | 175 | |

| 50 | 68 | 49 | 20 | 22 | 300 | 198 | |||||

| 65A | 85 | 12x1.75 | 35 | 57 | 21 | 23 | 285 | ||||

| 65B | 12x1.25 | 14 | |||||||||

| 75A | 95 | 12x1.75 | 35 | 65 | 27 | 400 | 325 | ||||

| 75B | 12x1.25 | 14 | |||||||||

Price list

| Quantity | 1~29 | 30~49 | 50~99 |

| Discount Rate | Unit Price | 5% | 10% |

Part Number

CAD Data download and 3D preview are not available because the part number has not yet been determined.

- *In order to open the CAD Data download and 3D preview screen, the part number must be fixed.

- Please confirm the part number from "Specification / Dimension"on the left side, and then perform the CAD Data Download / 3D Preview operation.

Loading...

More Information

Technical Information

Wheel Performance Comparison

| Item | Synthetic Rubber | Urethane Rubber | MC Nylon | Nylon (White) | Phenol |

|---|---|---|---|---|---|

| Abrasion Resistance | Excellent | Excellent | Excellent | Good | Good |

| Oil Resistance | Acceptable | Good | Excelente | Excelente | Excellent |

| Water Resistance | Excellent | Good | Excellent | Excellent | Good |

| Cost | Excellent | Good | Acceptable | Excellent | Acceptable |

| Noise | Excellent | Good | Acceptable | Inefficient | Acceptable |

| Allowable Load | Acceptable | Excellent | Excellent | Acceptable | Excellent |

| Moving Resistance | Acceptable | Good | Excellent | Good | Excellent |

| Rubber Hardness Shore A | 70±5 | 90±5 | — | — | — |

| Operating Temperature | -5–60°C | -20–80°C | -20–120°C | -10–120°C | -40–180°C |

| Features | Natural rubber SBR, BR etc. are combined in the ideal formulas and are the most standard type as general wheels. | Excellent in abrasion and oil resistance. Low starting and running resistance. | Excellent in oil resistance and load resistance. Low starting and running resistance. | Excellent in oil resistance and water resistance. Low starting and running resistance. | Excellent in oil, heat and load resistance. Low starting resistance. |

| Item | Special Reinforced Plastic | Conductive Rubber | Conductive MC Nylon | PEEK | Casting |

|---|---|---|---|---|---|

| Abrasion Resistance | Acceptable | Excellent | Excellent | Good | Excellent |

| Oil Resistance | Good | Acceptable | Excellent | Excellent | Excellent |

| Water Resistance | Good | Excellent | Excellent | Good | Good |

| Cost | Good | Good | Acceptable | Acceptable | Good |

| Noise | Acceptable | Excellent | Acceptable | Acceptable | Inefficient |

| Allowable Load | Excellent | Acceptable | Excellent | Excellent | Excellent |

| Moving Resistance | Good | Acceptable | Excellent | Good | Good |

| Rubber Hardness Shore A | — | 75±5 | — | — | — |

| Operating Temperature | -20–80°C | -5–60°C | -20–120°C | -50–250°C | -40–200°C |

| Features | Wider footprint than conventional wheels, and suitable for heavy loads. Relatively low cost. | SBR rubber compounded with a larger amount of carbon black content, which works as earthing. | Antistatic grease is sealed. Ideal for environments where dust adhesion is prohibited. | Excellent in heat resistance. Available for use at high temperature. | Excellent in abrasion, heat and corrosion resistance. |

Support Information

Variety of Wheels

| Specification | Properties | Specification | Properties |

|---|---|---|---|

Direct Mounting | Commonly used casters directly mounted with plates on carriages and machines. | ||

Screw Fitting | Just screw into pipes, frames, etc, to mount | ||

With Adjustment Pad | Integrated pads secure the Casters on the floor. | ||

Dual Wheels | Dual Wheel Type excellent in swivel and capable of making small turns. | ||

Vibration Absorption | Good vibration absorption and less dust generation during moving. Best use for clean environments. | ||

Casting | The type with high durability in harsh environments compared to the press-formed caster products. |

| Allowable Load / Specification | Light Load | Light-Medium Load | Medium Load | Low Profile | Medium-Heavy Load | Heavy Load | Super Heavy Load | Ultra Heavy Load |

|---|---|---|---|---|---|---|---|---|

| 80~400N | 300~1800N | 800~3000N | 1600~3200N | 3000N | 3000~6000N | 4000~9000N | ~15000N | |

Direct Mounting |  |  |  |  |  |  |  | |

| View all | View all | View all | View all | View all | View all | View all | ||

Screw Fitting |  |  |  |  | ||||

| View all | View all | View all | View all | |||||

With Adjustment Pad |  |  |  |  |  |  |  | |

| View all | View all | View all | View all | View all | View all | View all | ||

Dual Wheels |  |  |  | |||||

| View all | View all | View all | ||||||

Vibration Absorption |  |  | ||||||

| View all | View all | |||||||

Casting |  |  | ||||||

| View all | View all |

Find out more technical details about the wheels Here.

Cautions

1. Allowable Load

The allowable loads shown in the tables of the catalog indicate the limit load that can be transported by human power on a fl at surface

To calculate the total load limit first define the weight of the load be carried, then select a wheel with the appropriate allowable load. Even if 4 wheels are used the total load can be supported at 3 points, so the total load limit is usually calculated by the following formula:

Where:

- Lc: Limit of Total Load.

- Cp: Allowable Load.

- n: Number of wheels (in this example its value would be 4).

- The value of 0.8 is the multiplication factor to determine the total load at 3 support points.

[!] When different sizes of casters are used in combination, calculation should be based on the caster with the smallest load capacity.

2. Operating Speed

Operating speed should be walking speed or slower in intermittent usage. Avoid powered pulling (except for some casters) and continuous operation that may cause heat generation.

| Wheel Diameter | Operating Speed |

|---|---|

| 75mm or less | 2km/h or less |

| 100mm or less | 4km/h or less |

3. Stoppers

Note that the performance may degrade without user attention due to wear and damages from long-term operation. Braking power generally depends on wheel materials. To ensure safe use, use wheel stops, floor stoppers, etc.

4. Operating Environment

It is assumed that the casters are used in normal temperature. (Excluding some casters) Avoid unusual environment that might be affected by high temperature, low temperature, high humidity, acidic, alkaline, salt, solvent, oil, seawater and chemical products, etc.

Compatible Models

Basic Information

| Caster Type | Screw-In | Wheel Material | Rubber | Wheel Characteristics | Not Provided |

|---|---|---|---|---|---|

| Metal Piece(Fittings etc.,) Material | Steel | Thread Dia. M | M12 | Load Category | Light Load |

| Wheel Bearings | Not Provided |

Please check the type/dimensions/specifications of the part CLTUNS65B-R in the Casters - Threaded, with swivel plate, CLTUN series. series.

Specification/Dimensions

-

type

- CLTUN

- CLTUNS

-

Stopper

- Not Provided

- With Rotation Stopper

-

Load Range(daN)

- Up to 35.00

- 35.01 to 80.00

-

Allowable Load(daN)

-

Mounting Height H(mm)

-

Wheel Dia. D(φ)

-

Wheel Width B(mm)

-

Pitch P(mm)

- 1.25

- 1.75

-

CAD

- 2D

- 3D

Days to Ship

-

- All

- 8 Days or Less

Specify Alterations

- The specifications and dimensions of some parts may not be fully covered. For exact details, refer to manufacturer catalogs .

Products like this...

| Part Number |

|---|

| CLTUN65A-R |

| CLTUN65B-R |

| CLTUN75A-R |

| CLTUN75B-R |

| CLTUNS75A-R |

| CLTUNS75B-R |

Additional Products in this Category

- Casters - Angle turntable, SA series.

- Casters - Antistatic lll, for low platform, threaded, series HJ-SJ/HJB-SJ (Heavy loads).

- Casters - Urethane with mild steel swivel plate with bracket, MG-O, EU/MG-O series.

- Wheels - With suspension, double elastomer wheel and steel swivel plate, CT100 series.

- Casters - Rubber or urethane with steel swivel plate, without brake, type J (Medium load).

- Wheels - Rubber with aluminum swivel plate, without brake, TR-AWJ series (For trailer carts).

- Casters - Urethane or synthetic rubber with rolled steel swivel plate, without brake, K-630J series (With antistatic properties).

- Heavy Duty Industrial Large Top Plate Casters - Swivel, Ball Bearing, Impact Resistant Extra Heavy Gray Nylon Wheel, Stop-Fix Brake

Complementary Products

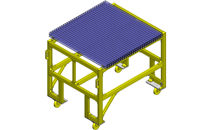

MISUMI Unit Example related to this product

Tech Support

- Technical Support

- Tel:+52-442-672-7661 ext. 2 then wait and dial 4

E-mail: soportetecnico@misumimex.com - Mon. - Fri. 8 a.m. - 6 p.m.

- Technical Inquiry

How can we improve?

How can we improve?

While we are not able to respond directly to comments submitted in this form, the information will be reviewed for future improvement.

Customer Privacy Policy

Thank you for your cooperation.

While we are not able to respond directly to comments submitted in this form, the information will be reviewed for future improvement.

Please use the inquiry form.

Customer Privacy Policy