(!)Due to Microsoft's end of support for Internet Explorer 11 on 15/06/2022, this site does not support the recommended environment.

Our Business Hours:

Mon. - Fri. 8 a.m. - 6 p.m.

Mon. - Fri. 8 a.m. - 6 p.m.

All Categories

Categories

- Automation Components

- Linear Motion

- Rotary Motion

- Connecting Parts

- Rotary Power Transmission

- Motors

- Conveyors & Material Handling

- Locating, Positioning, Jigs & Fixtures

- Inspection

- Sensors, Switches

- Pneumatics, Hydraulics

- Vacuum Components

- Hydraulic Equipment

- Spray Equipment And Accessories

- Pipe, Tubes, Hoses & Fittings

- Modules, Units

- Heaters, Temperature Control

- Aluminum Extrusions, Framing, Support & Posts

- Casters, Leveling Mounts, Posts

- Doors, Cabinet Hardware

- Springs, Shock Absorbers

- Adjustment/Fastening Components, Pins, Magnets

- Antivibration, Soundproofing Materials, Safety Products

- Fasteners

- Materials

- Wiring Components

- LAN Cables / Industrial Network Cables

- Equipment Specific Cables

- Cordsets

- Computer & AV Cables

- Wire/Cable

- Connector (General Purpose)

- Crimp Terminal Components

- Cable Organization

- Cable Gland Components

- Cable Bushing/Clip/Sticker

- Screw/Spacer

- Cable accessories

- Tube

- Electrical Conduits

- Duct/Wiring

- Electrical Wiring Tools

- Dedicated tools

- Soldering supplies

- Electrical & Controls

- Cutting Tools

- Carbide End Mill

- HSS End Mill

- Concrete Drill Bits

- Milling Cutter Insert / Holder

- Core Drill Bits

- Customized Straight Blade End Mill

- Dedicated Cutter

- Crinkey Cutters

- Turning Tool

- Drill

- Cutting Tool Accessories

- Screw Hole Related Tools

- Reamer

- Electric Drill Bits

- Chamfering, Centering Tool

- Hole Saws

- Magnetic Drill Press Cutters

- Step Drills

- Wood Drills & Cutters

- Processing Tools

- packing & logistics storage supplies

- Safety Products

- research and development & cleanroom supplies

- Press Die Components

- Plastic Mold Components

- Ejector Pins

- Sleeves, Center Pins

- Core Pins

- Sprue bushings, Gates, and other components

- Date Mark Inserts, Recycle Mark Inserts, Pins with Gas Vent

- Undercut, Plates

- Leader Components, Components for Ejector Space

- Mold Opening Controllers

- Cooling or Heating Components

- Accessories, Others

- Components of Large Mold, Die Casting

- Injection Molding Components

- Purging Agent

- Injection Molding Machine Products

- Accessories of Equipment

- Auxiliary Equipment

- Air Nippers

- Air Cylinders

- Air Chuck for Runner

- Chuck Board Components

- Frames

- Suction Components

- Parallel Air Chuck

- Special Air Chuck

- Mold Maintenance

- Heating Items

- Heat Insulation Sheets

- Couplers, Plugs, One-touch Joints

- Tubes, Hoses, Peripheral Components

Applications

Brands

- Webcode Seach | Series

-

#CODE

- Discontinued Products

- Scheduled Maintenance Notice: This site will be unavailable due to scheduled maintenance from 7:00 p.m. 11/23/2024 to 5:00 p.m. (CST) 11/24/2024. We apologize for the inconvenience.

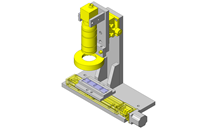

Manual X-Axis Stages - High Precision, Linear Ball Guide, XSG (XSCG40)

- Volume Discount

- Lead Time Reduction

High Precision, High Rigidity, but Low Price. If you don't need measurement, Feed Screw version is even lower in price.

- inCAD Components

(i)Caution

- Please check the content on our website as the PDF does not contain the most up-to-date information.

- Delivery times for some of our products may be delayed as national government authorities have imposed limit of capacity at our production sites.

Part Number

Configured Part Number is shown.

XSCG40

![[High Precision] X-Axis Stages - Linear Ball Guide:Related Image](http://mx.misumi-ec.com/en/linked/item/10300194450/img/drw_01_005.gif)

・Materials

[ ! ]For Micrometer Head and Feed Screw materials, Click here.

| Type | Main Body | Ball | Spring | Micrometer Head Bracket | Tip Holder | ||||

| [ M ]Material | [ S ]Surface Treatment | [ M ]Material | [ H ]Hardness | [ M ]Material | [ M ]Material | [ S ]Surface Treatment | [ M ]Material | [ S ]Surface Treatment | |

| XSG | 440C Stainless Steel | Electroless Nickel Plating | 440C Stainless Steel | 58HRC~ | 304 Stainless Steel PB | 5052 Aluminum Alloy | Clear Anodize | 303 Stainless Steel | - |

| XSCG | |||||||||

| XSBG | |||||||||

| XSDG | |||||||||

| XSKG | |||||||||

| XSGB | Low Temp. Black Chrome Plating | Black Anodize | Low Temp. Black Chrome Plating | ||||||

| XSCGB | |||||||||

Specifications

| Part Number |

| XSG80 |

■Micrometer Head (XSG, XSGB) / Feed Screw (XSCG, XSBG, XSCGB) [ ! ]Standard Stages Similar Products (available for limited sizes only): XLBS Click here

(*1)Stroke for XSCG80/100, XSBG80/100, XSCGB80 is ±6.5mm. (*2)Ends of feed screw knob are at 5mm inside of the carriage edges for XSCG and XSCGB. (*3) When dimension A of Feed Screw Type XSCG and XSCGB is 80 or 100, F will be 20.

· Performance

[ ! ]XSG, XSGB: Micrometer Head Resolution 10µm/division (*4)Straightness of XSGB and XSCGB40/60 is 3µm.

[ ! ]For orders larger than indicated quantity, please confirm with Web Ordering System.

■Digital Micrometer Heads (XSDG) / Coarse / Fine Micrometer Head (XSKG)

· Performance

[ ! ]XSKG: Coarse / Fine Micrometer Head Coarse Resolution 10µm, Fine Resolution 0.5µm XSDG: Digital Micrometer Head Resolution 1µm

[ ! ]Knob Cover HDCVR13 (Sold Separately): Ø13 micrometer knob diameter can be increased by installing the cover. >> Click here

[ ! ]Extension Cover HDEXT13 (Sold Separately): Ø13 micrometer head or feed screw knobs can be extended by installing the cover. >> Click here

[ ! ]For orders larger than indicated quantity, please confirm with Web Ordering System.

| Part Number | Top View | Front View | Side View | Accessories (4 pcs.) | |||||||||||||||

| Type | A | (B) | Travel Distance (mm) | E | F | J | K | D | G | T | T1 | P | Q | X | d1 | d2 | ℓ | TypeM-L | |

| Micrometer | Feed Screw | ||||||||||||||||||

| XSG XSCG XSBG (40≤A≤100) XSGB (* only) XSCGB (* only) | 25* | 25 | 11 | ±3.2 | 7 | 9 | 6.8 | 15 | 9.3 | 7 | 12 | 3.7 | 6 | 8.5 | 20 | 2.5 | 4.2 | 2.5 | SCB2-4 |

| 40* | 24 | 20.3 | ±6.5 | 12 | 18.5 | 11.5 | 26 | 13 | 9 | 16 | 4.5 | 10 | 10.5 | 32 | 3.5 | 6 | 3.5 | SCB3-6 | |

| 50 | 19 | 15.3 | 12 | 18.5 | 11.5 | 31 | 13 | 9 | 16 | 4.5 | 10 | 10.5 | 40 | 3.5 | 6 | 3.5 | SCB3-6 | ||

| 60* | 14 | 10.3 | 12 | 18.5 | 11.5 | 36 | 13 | 9 | 16 | 5 | 10 | 10.5 | 50 | 4.5 | 8 | 4 | SCB4-6 | ||

| 70 | 14.5 | 10.8 | 12 | 18.5 | 11.5 | 46.5 | 13 | 10 | 18 | 6 | 10 | 11.5 | 60 | 4.5 | 8 | 4.5 | SCB4-6 | ||

| 80* | 43.5 | 10 | ±12.5(*1) | 17 | 22(*3) | 11.5 | 55 | 18 | 11 | 20 | 6.5 | 10 | 14.5 | 70 | 4.5 | 8 | 5.3 | SCB4-6 | |

| 100 | 28.5 | -5(*2) | 17 | 22(*3) | 11.5 | 67.5 | 18 | 11 | 20 | 6.5 | 10 | 14.5 | 90 | 4.5 | 8 | 5.3 | SCB4-6 | ||

· Performance

| Part Number | Stage Surface (mm) | Load Capacity (N) | Travel Accuracy | Moment Load Capacity (N·m) | Moment Rigidity ("/N·cm) | Parallelism | Weight (kg) | ||||||||||

| Type | A | Horizontal | Vertical | Straightness | Motion Parallelism | Pitching | Yawing | Pitching | Yawing | Rolling | Pitching | Yawing | Rolling | Micrometer | Feed Screw | ||

| XSG XSCG XSBG (40≤A≤100) XSGB (* only) XSCGB (* only) | 25* | 25x25 | 39.2 | 9.8 | 3µm | 10µm | 30" | 25" | 2.0 | 2.0 | 3.5 | 1.9 | 1.1 | 1.1 | 30µm | 0.07 | 0.09 |

| 40* | 40x40 | 98 | 49 | 1µm (*4) | 7µm | 25" | 15" | 5.0 | 5.0 | 5.0 | 0.42 | 0.35 | 0.21 | 15µm | 0.23 | 0.23 | |

| 50 | 50x50 | 147 | 6.8 | 6.8 | 6.0 | 0.15 | 0.14 | 0.09 | 0.28 | 0.28 | |||||||

| 60* | 60x60 | 196 | 10.0 | 10.0 | 9.0 | 0.08 | 0.08 | 0.05 | 0.40 | 0.40 | |||||||

| 70 | 70x70 | 225.4 | 13.8 | 13.8 | 12.9 | 0.06 | 0.05 | 0.03 | 0.58 | 0.58 | |||||||

| 80* | 80x80 | 264.6 | 3µm | 8µm | 18.2 | 18.2 | 17.7 | 0.04 | 0.04 | 0.02 | 20µm | 0.90 | 0.84 | ||||

| 100 | 100x100 | 343 | 31.8 | 31.8 | 30.7 | 0.02 | 0.02 | 0.01 | 1.33 | 1.27 | |||||||

[ ! ]For orders larger than indicated quantity, please confirm with Web Ordering System.

■Digital Micrometer Heads (XSDG) / Coarse / Fine Micrometer Head (XSKG)

| Part Number | Top View | Front View | Side View | Accessories (4 pcs.) | |||||||||||||

| Type | A | XSDG | XSKG | E | F | K | G | T | T1 | Q | X | d1 | d2 | ℓ | TypeM-L | ||

| (B) | Travel Distance (mm) | (B) | Travel Distance (mm) | ||||||||||||||

| XSDG XSKG (40≤A≤80) | 40 | 121.5 | ±6.5 | 60 | Coarse Feed ±6.5 Fine Feed 0.2 | 16 | 18.5 | 26 | 11.6 | 16 | 4.5 | 10.5 | 32 | 3.5 | 6 | 3.5 | SCB3-6 |

| 50 | 116.5 | 55 | 16 | 18.5 | 31 | 11.6 | 16 | 4.5 | 10.5 | 40 | 3.5 | 6 | 3.5 | SCB3-6 | |||

| 60 | 111.5 | 50 | 16 | 18.5 | 36 | 11.4 | 16 | 5 | 10.5 | 50 | 4.5 | 8 | 4 | SCB4-6 | |||

| 70 | 112 | 50.5 | 16 | 18.5 | 46.5 | 12.5 | 18 | 6 | 11.5 | 60 | 4.5 | 8 | 4.5 | SCB4-6 | |||

| 80 | 104 | ±12.5 | 49.5 | 17 | 25 | 55 | 10.8 | 20 | 6.5 | 14.5 | 70 | 4.5 | 8 | 5.3 | SCB4-6 | ||

| 100 | 89 | - | - | - | 67.5 | - | 20 | 6.5 | 14.5 | 90 | 4.5 | 8 | 5.3 | SCB4-6 | |||

| Part Number | Stage Surface | Load Capacity (N) | Travel Accuracy | Moment Load Capacity (N·m) | Moment Rigidity ("/N·cm) | Parallelism | Weight (kg) | ||||||||||

| Type | A | (mm) | Horizontal | Vertical | Straightness | Motion Parallelism | Pitching | Yawing | Pitching | Yawing | Rolling | Pitching | Yawing | Rolling | XSDG | XSKG | |

| XSDG XSKG (40≤A≤80) | 40 | 40x40 | 98 | 49 | 1µm | 7µm | 25" | 15" | 5.0 | 5.0 | 5.0 | 0.42 | 0.35 | 0.21 | 15µm | 0.43 | 0.30 |

| 50 | 50x50 | 147 | 6.8 | 6.8 | 6.0 | 0.15 | 0.14 | 0.09 | 0.48 | 0.35 | |||||||

| 60 | 60x60 | 196 | 10.0 | 10.0 | 9.0 | 0.08 | 0.08 | 0.05 | 0.60 | 0.47 | |||||||

| 70 | 70x70 | 225.4 | 13.8 | 13.8 | 12.9 | 0.06 | 0.05 | 0.03 | 0.78 | 0.65 | |||||||

| 80 | 80x80 | 264.6 | 3µm | 8µm | 18.2 | 18.2 | 17.7 | 0.04 | 0.04 | 0.02 | 20µm | 1.10 | 0.97 | ||||

| 100 | 100x100 | 343 | 31.8 | 31.8 | 30.7 | 0.02 | 0.02 | 0.01 | 1.53 | - | |||||||

[ ! ]Knob Cover HDCVR13 (Sold Separately): Ø13 micrometer knob diameter can be increased by installing the cover. >> Click here

[ ! ]Extension Cover HDEXT13 (Sold Separately): Ø13 micrometer head or feed screw knobs can be extended by installing the cover. >> Click here

[ ! ]For orders larger than indicated quantity, please confirm with Web Ordering System.

Alterations

![[High Precision] X-Axis Stages - Linear Ball Guide:Related Image](http://mx.misumi-ec.com/en/linked/item/10300194450/img/alt_01.gif)

[ ! ]For micrometer head or feed screw mounted in positions other than shown below, see "Specifi cation Selectable Type". >> Click here

Part Number

CAD Data download and 3D preview are not available because the part number has not yet been determined.

- *In order to open the CAD Data download and 3D preview screen, the part number must be fixed.

- Please confirm the part number from "Specification / Dimension"on the left side, and then perform the CAD Data Download / 3D Preview operation.

Loading...

| Part Number |

|---|

| XSCG40 |

Loading...

More Information

![[High Precision] X-Axis Stages - Linear Ball Guide:Related Image](http://mx.misumi-ec.com/en/linked/item/10300194450/img/oth_01.gif)

Basic Information

| Guiding Mechanism | Linear Ball | Table Material | 440C Stainless Steel | Type | X-Axis |

|---|---|---|---|---|---|

| Feed Knob Position | Side | Clamp | Standard | Reversed | Standard |

| Through Hole | No |

Please check the type/dimensions/specifications of the part XSCG40 in the Manual X-Axis Stages - High Precision, Linear Ball Guide, XSG series.

Specification/Dimensions

-

Feed method (micrometer type)

- Coarse/Fine Feed

- Digimatic

- Standard

-

type

- XSBG

- XSCG

- XSCGB

- XSDG

- XSG

- XSGB

- XSKG

-

Travel Distance (Selection Range)

-

Load Capacity (Range)(N)

-

Table Length L (Range)(mm)

-

Table Width W (Range)(mm)

-

Overall Height (Range)(mm)

-

Feeding Method

- Feed Screw

- Micrometer Head

-

Table Surface Treatment

- Electroless Nickel Plating

- Low Temperature Black Chrome Plating

-

Table Size (Length) L(mm)

-

Table Size (Width) W(mm)

-

Allowable Load(N)

-

Travel Distance (X Distance)(mm)

-

Table Size (Thickness) H(mm)

-

Feed method (feed screw type)

- Knob

-

Feed method (travel distance per 1 handle rotation)(mm)

-

CAD

- 2D

- 3D

Days to Ship

-

- All

- 8 Days or Less

- 10 Days or Less

- 12 Days or Less

Specify Alterations

- The specifications and dimensions of some parts may not be fully covered. For exact details, refer to manufacturer catalogs .

Frequently asked questions (FAQ)

- 質問: What directions are pitch, roll, and yaw?

- 回答: The best explanation can be fount at: https://us.c.misumi-ec.com/book/usa_2013_msm_fa_02/pdf/1687.pdf

Products like this...

| Part Number |

|---|

| XSCG25 |

| XSCG60 |

| XSCG80 |

| XSDG80 |

| XSG25 |

| XSG40 |

Additional Products in this Category

- Manual X-Axis Stages - Dovetail, Feed Screw, XEG

- Manual X-Axis Stages - High Precision X-Axis, Dovetail, Hex Wrench Drive, XEEG

- Manual X-Axis Stages - High Precision, Square Dovetail, Standard, XSC

- Manual X-Axis Stages - High Precision, Linear Guide, XLSG

- Manual X-Axis Stages - Dovetail, Feed Screw, Screw Replacable Type, XEGL

- Manual X-Axis Stages - Slide Guide, Long Stroke, B15

- Manual X-Axis Stages - Dovetail, Feed Screw, Short Lead, B08/BDBXS/BDBXR

- Manual X-Axis Stages - Cross Roller, Aluminum, TAM

Complementary Products

MISUMI Unit Example related to this product

Tech Support

- Technical Support

- Tel:+52-442-672-7661 ext. 2 then wait and dial 4

E-mail: soportetecnico@misumimex.com - Mon. - Fri. 8 a.m. - 6 p.m.

- Technical Inquiry

How can we improve?

How can we improve?

While we are not able to respond directly to comments submitted in this form, the information will be reviewed for future improvement.

Customer Privacy Policy

Thank you for your cooperation.

While we are not able to respond directly to comments submitted in this form, the information will be reviewed for future improvement.

Please use the inquiry form.

Customer Privacy Policy