(!)Debido al final de soporte anunciado por Microsoft para Internet Explorer 11 con fecha del 15/06/2022, este sitio no recomienda el uso de ese navegador.

Lunes a viernes de 8 a. m. a 6 p. m.

Categorías de Productos

-

Automatización

Automatización

Show all categories of Automatización-

Movimiento lineal

-

Movimiento Rotativo

-

Partes Conectoras

-

Transmisión de potencia rotativa

-

Motores

-

Transportadores y manejo de materiales

-

Localización, posicionamiento, jigs y accesorios

-

Inspección

-

Sensores, interruptores

-

Neumática, Hidráulica

-

Componentes para vacío

-

Equipo hidráulico

-

Equipo de pulverización y accesorios

-

Tuberías, tubos, mangueras y accesorios

-

Módulos, Unidades

-

Calentadores, control de temperatura

-

Extrusiones de aluminio, marcos, soportes y postes

-

Rodajas, Niveladores para maquinaria, postes

-

Puertas, Herrajes para gabinetes

-

Resortes, amortiguadores

-

Componentes de ajuste / fijación, pasadores, imanes

-

Antivibración, Materiales de aislamiento acústico, Productos de seguridad

-

- Sujetadores y Tornillos

- Materiales

-

Componentes para Cableado

Componentes para Cableado

Show all categories of Componentes para Cableado-

Cables LAN / Cables de red industrial

-

Equipo soportado cable

-

Cable con conector

-

RS232 / computadora personal / cable AV

-

Cable de alambre

-

Conector (uso general)

-

Terminal de crimpado

-

Cremallera

-

Glándulas de cable

-

Cable Buje / Clip / Etiqueta

-

Tornillo / espaciador

-

Accesorios de cable

-

Tubo

-

Protección de Manguera

-

Conducto / Cableado

-

Herramienta de uso general

-

Herramientas para conexión

-

Suministros de soldadura

-

- Electrónica y Controles

-

Herramientas de Corte

Herramientas de Corte

Show all categories of Herramientas de Corte-

Fresa de metal duro

-

HSS End Mill

-

Brocas de hormigón

-

Inserto / soporte de fresa

-

Brocas para taladro

-

Fresa de extremo de hoja recta personalizada

-

Cortador dedicado

-

Fresa de Llave

-

Herramienta de torneado

-

Perforar

-

Accesorios para herramientas de corte

-

Herramientas relacionadas con agujeros de tornillo

-

Escariador

-

Brocas eléctricas

-

Biselado, herramienta de centrado

-

Sierras de agujero

-

Cortadores de prensa de taladro magnético

-

Taladro Escalonado

-

Taladros y cortadores de madera

-

-

Herramientas para Proceso

Herramientas para Proceso

Show all categories of Herramientas para Proceso-

Herramienta de máquina

-

Herramientas de medida / Equipos de medida

-

Herramienta de descarga eléctrica

-

Suministros de soldadura

-

Suministros de pulido

-

Suministros para corte

-

Herramientas manuales

-

Herramienta eléctrica

-

Herramienta neumática

-

Productos químicos

-

Material de reparación / adhesivo

-

Productos de soldadura / antiestáticos

-

-

Suministros de Embalaje y Almacenamiento Logístico

Suministros de Embalaje y Almacenamiento Logístico

Show all categories of Suministros de Embalaje y Almacenamiento Logístico -

Productos de seguridad

Productos de seguridad

Show all categories of Productos de seguridad -

Investigación/Desarrollo y Suministros para Salas Blancas

Investigación/Desarrollo y Suministros para Salas Blancas

Show all categories of Investigación/Desarrollo y Suministros para Salas Blancas - Componentes para Prensado

-

Moldeado de Plástico

Moldeado de Plástico

Show all categories of Moldeado de Plástico-

Pines Eyectores

-

Mangas, pasadores centrales

-

Pines de corazón

-

Boquillas y componentes de entrada

-

Fechadores, Insertos de Marca de Reciclaje, Pines con ventilación de gas

-

Socavado, placas

-

Componentes Guia, componentes para espacio eyector

-

Controladores de apertura del molde

-

Componentes de enfriamiento o calentamiento

-

Accesorios, otros

-

Componentes de moldes grandes, fundición a presión

-

-

Moldeado por Inyección

Moldeado por Inyección

Show all categories of Moldeado por Inyección-

Agente Purgante

-

Productos Maquinados por Moldeo de Inyección

-

Accesorios de equipamiento

-

Equipo auxiliar

-

Pinzas de corte neumáticas

-

Cilindros de aire

-

Componentes para sujeción neumática

-

Componentes para tablero de botador

-

Marcos

-

Compuestos de succión

-

Mandril paralelo

-

Portabrocas especial

-

Mantenimiento del molde

-

Artículos de calefacción

-

Hojas para aislamiento térmico

-

Acopladores, tapones, juntas de un toque

-

Tubos, mangueras, componentes periféricos

-

- Búsqueda de código Web | Serie

-

N.º DE CÓDIGO

- Productos descontinuados

Loading...

Article of Interest: Business Benefits of Standardizing on Configurable vs. Custom Components

Business Benefits of Standardizing on Configurable vs. Custom Components

Featured Article – Design Engineering (Canada) Magazine (September 2011)

By: Patrick J. Esposito, Marketing Manager, MISUMI USA

Even in a tight economy, machine building OEMs can find new ways to reduce costs and maximize profit margins, while improving quality and customer service.

Business Benefits of Standardizing on Configurable vs. Custom Components

In challenging economic times, manufacturing companies serving the consumer and industrial electronics market are striving to remain competitive by reducing costs while increasing efficiency and productivity. These are tough goals to achieve when the costs of materials and supplies, energy and plant operations, transportation and logistics have been steadily rising.

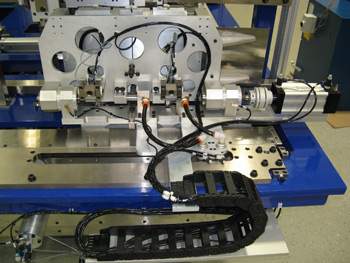

MISUMI Genesis

Automotive parts presentation fixture

One way progressive producers of automated motion control equipment have found to reduce development and manufacturing costs is by standardizing machine components wherever feasible and by using configurable machine components that can be quickly and easily integrated into their products without incurring additional machining or finishing time and costs.

A Practical Alternative

Purchasing configurable components from a reliable outside source can not only reduce production costs, but can also save significant time and effort at the front end, in the design and procurement processes. The fact is that, in making and assembling their products, automation machine builders and integrators typically deploy a wide range of motion control components, such as linear shafts, actuators, bushings, linear guides, locating pins, ball screws and machined steel plates and associated hardware.

If manufacturers could order all of these components from a single source, configured to their specific and precise requirements regarding dimensions, materials and finishes – and do so at reasonable prices and fast turnaround times – the benefits would be significant. Increased efficiency, higher productivity and faster time-to-market are just a few advantages.

Here’s a brief look at how a prominent Canadian machine builder has adopted the configurable component alternative and reaped significant measurable returns.

ATS Automation Tooling Systems

ATS Automation Tooling Systems, Inc. of Cambridge, ON, provides innovative, custom designed and built manufacturing solutions to many of the world's most successful companies. Founded in 1978, ATS serves the sophisticated automation systems' needs of multinational customers in industries such as healthcare, computer/electronics, automotive and consumer products. ATS employs approximately 2,700 people at 17 manufacturing facilities in Canada, the United States, Europe, Southeast Asia and China.

ATS discovered the value and convenience of specifying MISUMI’s configurable components as the company was planning the launch of its modular FlexsysPAK System. The FlexsysPAK System is an automated packaging, assembly and dispensing platform based on the company’s Supertrak pallet conveyor line. Such a complex, configurable system would typically require substantial lead time because of the vast number of components involved in its design and production.

According to the ATS CAD support specialist for the company’s mechanical design group, using MISUMI’s easy-to-access online Configurator and ordering system was instrumental in saving time and labor for engineers responsible for designing and specifying components for the FlexsysPAK machinery. Previously, in modeling a new part, design engineers would need to find a catalog, either online or hard copy, then model the part from the dimensions provided, which increased the possibility of modeling errors and the need for rework.

Using MISUMI’s CAD configurator and online ordering system during the development process, ATS engineers could use either two-dimensional drawings or CAD files available on the MISUMI website. Designers could input a part number, reconfigure the part and then download the native 3-D file. In most cases, this took considerably less time than it took before to create detailed drawings of the components.

To further facilitate the process, MISUMI provides standard automation components that can be parametrically configured to the precise specifications required for the unique assembly being designed. When the part design is completed, the designer can download the native CAD file directly into the assembly model. The component can then be added to the bill of material as a purchased item.

Various component materials and surface finishes can also be specified through the MISUMI catalog or e-catalog part number, while dimensional specifications can be selected in 1-millimeter increments. Additional configuration options available include wrench flats, location of wrench flats, set screw flats, key grooves and V-grooves.

ATS is just one example of the value proposition of configurable components and convenient online configuration and ordering. Other leading machine builders have reported similar positive results, including:

- Time savings of up to 60 percent due to ordering of precision configured machined parts

- Cost savings of up to 50 percent over the expense of in-house custom production and machining

- Greater modularity and flexibility of systems and interoperability of parts

- Higher productivity, reduced build time, and faster time-to-market

An additional plus unique to MISUMI’s business model is the company’s “no minimum order” policy and guaranteed delivery of many of its 1,000,000 configurable components within days rather than the weeks (or months) typically required. This allows manufacturers to design and make prototype machinery and systems, or even one-off specialty devices, economically and quickly.

About the Author

Patrick Esposito, Marketing Manager for MISUMI USA, has 25 years of professional experience in the industrial manufacturing sector. He has held executive positions in Product Management and Sales and Marketing Management, and has authored numerous articles and white papers for a wide range of industrial trade publications.

About the Company

MISUMI USA is a leading global supplier of fixed and configurable mechanical components used in the design and manufacture of factory automation machinery and systems. For more information, visit https://mx.misumi-ec.com/es.