(!)Due to Microsoft's end of support for Internet Explorer 11 on 15/06/2022, this site does not support the recommended environment.

Our Business Hours:

Mon. - Fri. 8 a.m. - 6 p.m.

Mon. - Fri. 8 a.m. - 6 p.m.

All Categories

Categories

- Automation Components

- Linear Motion

- Rotary Motion

- Connecting Parts

- Rotary Power Transmission

- Motors

- Conveyors & Material Handling

- Locating, Positioning, Jigs & Fixtures

- Inspection

- Sensors, Switches

- Pneumatics, Hydraulics

- Vacuum Components

- Hydraulic Equipment

- Spray Equipment And Accessories

- Pipe, Tubes, Hoses & Fittings

- Modules, Units

- Heaters, Temperature Control

- Aluminum Extrusions, Framing, Support & Posts

- Casters, Leveling Mounts, Posts

- Doors, Cabinet Hardware

- Springs, Shock Absorbers

- Adjustment/Fastening Components, Pins, Magnets

- Antivibration, Soundproofing Materials, Safety Products

- Fasteners

- Materials

- Wiring Components

- LAN Cables / Industrial Network Cables

- Equipment Specific Cables

- Cordsets

- Computer & AV Cables

- Wire/Cable

- Connector (General Purpose)

- Crimp Terminal Components

- Cable Organization

- Cable Gland Components

- Cable Bushing/Clip/Sticker

- Screw/Spacer

- Cable accessories

- Tube

- Electrical Conduits

- Duct/Wiring

- Electrical Wiring Tools

- Dedicated tools

- Soldering supplies

- Electrical & Controls

- Cutting Tools

- Carbide End Mill

- HSS End Mill

- Concrete Drill Bits

- Milling Cutter Insert / Holder

- Core Drill Bits

- Customized Straight Blade End Mill

- Dedicated Cutter

- Crinkey Cutters

- Turning Tool

- Drill

- Cutting Tool Accessories

- Screw Hole Related Tools

- Reamer

- Electric Drill Bits

- Chamfering, Centering Tool

- Hole Saws

- Magnetic Drill Press Cutters

- Step Drills

- Wood Drills & Cutters

- Processing Tools

- packing & logistics storage supplies

- Safety Products

- research and development & cleanroom supplies

- Press Die Components

- Plastic Mold Components

- Ejector Pins

- Sleeves, Center Pins

- Core Pins

- Sprue bushings, Gates, and other components

- Date Mark Inserts, Recycle Mark Inserts, Pins with Gas Vent

- Undercut, Plates

- Leader Components, Components for Ejector Space

- Mold Opening Controllers

- Cooling or Heating Components

- Accessories, Others

- Components of Large Mold, Die Casting

- Injection Molding Components

- Purging Agent

- Injection Molding Machine Products

- Accessories of Equipment

- Auxiliary Equipment

- Air Nippers

- Air Cylinders

- Air Chuck for Runner

- Chuck Board Components

- Frames

- Suction Components

- Parallel Air Chuck

- Special Air Chuck

- Mold Maintenance

- Heating Items

- Heat Insulation Sheets

- Couplers, Plugs, One-touch Joints

- Tubes, Hoses, Peripheral Components

Applications

Brands

- Webcode Seach | Series

-

#CODE

- Discontinued Products

- Scheduled Maintenance Notice: This site will be unavailable due to scheduled maintenance from 7:00 p.m. 2/22 to 5:00 p.m. (CST) 2/23/2025. We apologize for the inconvenience.

Flexible Couplings - Disc type, high positioning accuracy.

Most Suitable especially for Use for High-Presicion required Devices and in Clean Environment.

- METRIC

- inCAD Components

Part Number

Configured Part Number is shown.

・Materials

| Type | [ M ]Material | [ S ]Surface Treatment | [ A ]Accessories | ||||

| Body | Disc | Screw | Body | Disc | Screw | ||

| SCXW SCXWK | Aluminum Alloy | Stainless Steel | 4137 Alloy Steel | Clear Anodize | - | Trivalent Chromate | Hex Socket Head Cap Screw, Set Screw |

Specifications

| Part Number | - | Shaft Bore Dia. d1 | - | Shaft Bore Dia. d2 |

| SCXW46 | - | 10 | - | 14 |

| SCXWK46 | - | 12 | - | 14 |

| SCPW34 | - | 8 | - | 12 |

| Part Number | d1, d2 (d1≤d2) [ ! ]Only the dimensions in ( ) are selectable for Keywayed Bore Type. | D | d3 | L | ℓ | F | A | Clamp Screw | ||||||||||||||||

| Type | No. | M | Tightening Torque (N·m) | |||||||||||||||||||||

| SCXW | SCXWK | |||||||||||||||||||||||

| Double Disc Type SCXW Double Disc Type - Keywayed Bore SCXWK | 21 | 4 | 5 | 6 | (8) | 21 | 9.5 | 24.5 | 7 | 3.5 | 3 | 7 | M2.6 | 1.2 | ||||||||||

| 28 | 5 | 6 | (8) | (10) | 28 | 12 | 32 | 9 | 4 | 4 | 9.5 | M3 | 1.5 | |||||||||||

| 34 | 6 | (8) | (10) | (12) | (14) | 34 | 17 | 35 | 9.8 | 5 | 4.5 | 12 | M3 | 1.5 | ||||||||||

| 46 | 8 | (10) | (12) | (14) | 15 | 17 | 19 | 46 | 22 | 44 | 12.6 | 6 | 6 | 16.5 | M4 | 3.5 | ||||||||

| 55 | 12 | 14 | 15 | 17 | 19 | 20 | 22 | 24 | 25 | 54.5 | 26 | 55 | 16 | 7 | - | 20.5 | M5 | 7 | ||||||

| Part Number | Allowable Torque (N·m) | Angular Misalignment (°) | Lateral Misalignment (mm) | Static Torsional Spring Constant (N·m/rad) | Max. Rotational Speed (r/min) | Moment of Inertia (kg·m2) | Allowable Axial Misalignment (mm) | Compensation Factor | Mass (g) | |

| Type | No. | |||||||||

| SCXW SCXWK | 21 | 1.2 | 1.0 | 0.10 | 900 | 10000 | 1.20x10-6 | ±0.20 | 1.5 | 18 |

| 28 | 1.6 | 1.2 | 0.15 | 3600 | 4.68x10-6 | 42 | ||||

| 34 | 4.0 | 1.5 | 0.20 | 5700 | 1.10x10-5 | 65 | ||||

| 46 | 10.0 | 0.25 | 14500 | 4.70x10-5 | ±0.30 | 151 | ||||

| 55 | 25.0 | 23000 | 1.19x10-4 | 260 | ||||||

Price list

■Volume Discount Rate ([ ! ]Round down to nearest one cent.) Click here

[ ! ]For orders larger than indicated quantity, please request a quotation.

| Quantity | 1~9 | 10~14 | 15~19 |

| Discount Rate | Unit Price | 5% | 10% |

More Information

Technical Information

Keyway Dimensions

| Shaft Bore Dia. d1, d2 | b | t | Key Nom. Dim. b x h | Set Screw | |||

|---|---|---|---|---|---|---|---|

| Dim. | Tolerance | Dim. | Tolerance | Size | Tightening Torque (N・m) | ||

| 8-10 | 3 | ±0.0125 | 1.4 | +0.1 0 | 3x3 | M2 | 0.3 |

| 12 | 4 | ±0.0150 | 1.8 | 4x4 | M3 | 0.7 | |

| 14 | 5 | 2.3 | 5x5 | M4 | 1.7 | ||

Support Information

MISUMI Coupling Type

| Coupling Type | Disk Tye | With Slit Type | Oldham Type | Jaw Type | Bellows Type | Rigid Type | Universal Joints Type | Chain Couplings Type |

|---|---|---|---|---|---|---|---|---|

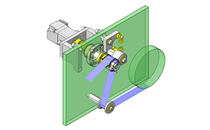

| Photo |  |  |  |  |  |  |  |  |

| Shaft Bore Dia | Ø2-60 mm | Ø1.5-35 mm | Ø1-47 mm | Ø3-60 mm | Ø0-62 mm | Ø3-35 mm | Ø1-60 mm | Ø14-55 mm |

| Mortor Recommendation | *Servo Motor *Stepping Motors | *Servo Motor *Stepping Motors | *General Purpose Morter | *Stepping Motors *General Purpose Morter | *Stepping Motors | *Servo Motor *Stepping Motors | *Stepping Motors *General Purpose Morter | *General Purpose Morter |

| Torque | 0.15-800 N·m | 0.05-35 N·m | 0.06-352 N·m | 0.31-1,350 N·m | 0.3-500 N·m | 0.3-206 N·m | 0.25-495 N·m | 100-2,372 N·m |

| Zero Backlash | Excellent | Excellent | Inefficient | Inefficient | Good | Excellent | Inefficient | Inefficient |

| Allowable Angular Misalignment | Good | Good | Excellent | Reasonable | Excellent | Inefficient | Excellent | Reasonable |

| Allowable Lateral Misalignment | Reasonable | Reasonable | Excellent | Reasonable | Reasonable | Inefficient | Inefficient | Reasonable |

| Axial Misalignment | Good | Reasonable | Good | Inefficient | Excellent | Inefficient | Inefficient | Inefficient |

| See all options | Click here | Click here | Click here | Click here | Click here | Click here | Click here | Click here |

For more details on each type of coupling click here

Features

Disc Couplings

Zero backlash, and best suited for high torque servo motor applications. characteristics.

- Designed to absorb misalignments by disc flexures.

- Zero backlash nature provides high angular accuracy, suitable for applications requiring high positioning accuracies.

- The High Rigidity Type couplings have largely improved torsional rigidity over the Standard Types due to screw-coupled discs instead of the swage-coupled discs of the Standard.

Cautions

Use Precautions

- Make sure to keep misalignment within the allowed range and avoid excessive torque. Otherwise the coupling’s life will be shortened considerably due to plastic deformation.

- For your safety, enclose the revolving parts of equipment with a protective cover.

- If the coupling item generates abnormal metallic noises, immediately turn off the equipment and identify the cause. Such noises may be an indication of improper alignment, shaft interference or a loose screw.

- For applications with a large load fluctuation, apply an adhesive agent on the coupling’s screws to prevent them from loosening. Alternatively, select a coupling of a larger size/load capability.

Compatible Models

Part Number

CAD Data download and 3D preview are not available because the part number has not yet been determined.

- *In order to open the CAD Data download and 3D preview screen, the part number must be fixed.

- Please confirm the part number from "Specification / Dimension"on the left side, and then perform the CAD Data Download / 3D Preview operation.

Loading...

| Part Number |

|---|

| SCXW21-[4,5,6,8]-[4,5,6,8] |

| SCXW28-[5,6,8,10]-[5,6,8,10] |

| SCXW34-[6,8,10,12,14]-[6,8,10,12,14] |

| SCXWK21-8-8 |

| SCXWK28-[8,10]-[8,10] |

| SCXWK34-[8,10,12,14]-[8,10,12,14] |

Loading...

Example

Basic Information

| Series Name | Disc Type | Allowable Misalignment | Angular / Eccentricity / Axial | Application | For Servo Motors |

|---|---|---|---|---|---|

| Max. Rotational Speed Range(r/min) | 4001~10000 | Features | High Torsional Rigidity / High Torque Type / High Positioning Accuracy Type / Zero Backlash / Low Moment of Inertia / Clean Environment | Body Material | Aluminum |

| Category | Coupling Main Body | Max. Rotational Speed(r/min) | 10000 | Disc Material | Stainless Steel |

| Single/Double | Double |

Specification/Dimensions

-

Allowable Torque Range(N•m)

-

For Shaft Size d1(mm)

-

For Shaft Size d2(mm)

-

O.D. D(Ø)

-

Overall Length(mm)

-

Allowable Torque(N•m)

-

Allowable Angular Misalignment(deg)

-

Allowable Lateral Misalignment(mm)

-

Shaft Bore Shape

-

type

- SCXW

- SCXWK

-

Allowable Lateral Misalignment Range(mm)

-

CAD

- 2D

- 3D

Days to Ship

-

- All

- 8 Days or Less

Specify Alterations

- The specifications and dimensions of some parts may not be fully covered. For exact details, refer to manufacturer catalogs .

Additional Products in this Category

- Flexible Couplings - Spacer for Oldham type coupling.

- Flexible Couplings - Oldham type, clamping type.

- Flexible Couplings - With clamp type fastening and sintered steel body.

- Flexible Couplings - Oldham type, clamp-on type, serrated spacer.

- Flexible Couplings - With rubber separator.

- Flexible Couplings - Precision axially adjustable spring type, series LCS-B.

- Flexible Couplings - Single disc, clamp-on, XHS/XHW/XHW-L series.

- Flexible Couplings - Oldham Type, MOM series.

Complementary Products

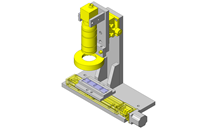

MISUMI Unit Example related to this product

Tech Support

- Technical Support

- Tel:+52-442-672-7661 ext. 2 then wait and dial 4

E-mail: soportetecnico@misumimex.com - Mon. - Fri. 8 a.m. - 6 p.m.

- Technical Inquiry

How can we improve?

How can we improve?

While we are not able to respond directly to comments submitted in this form, the information will be reviewed for future improvement.

Customer Privacy Policy

Thank you for your cooperation.

While we are not able to respond directly to comments submitted in this form, the information will be reviewed for future improvement.

Please use the inquiry form.

Customer Privacy Policy