(!)Due to Microsoft's end of support for Internet Explorer 11 on 15/06/2022, this site does not support the recommended environment.

Mon. - Fri. 8 a.m. - 6 p.m.

All Categories

Categories

- Automation Components

- Linear Motion

- Rotary Motion

- Connecting Parts

- Rotary Power Transmission

- Motors

- Conveyors & Material Handling

- Locating, Positioning, Jigs & Fixtures

- Inspection

- Sensors, Switches

- Pneumatics, Hydraulics

- Vacuum Components

- Hydraulic Equipment

- Spray Equipment And Accessories

- Pipe, Tubes, Hoses & Fittings

- Modules, Units

- Heaters, Temperature Control

- Aluminum Extrusions, Framing, Support & Posts

- Casters, Leveling Mounts, Posts

- Doors, Cabinet Hardware

- Springs, Shock Absorbers

- Adjustment/Fastening Components, Pins, Magnets

- Antivibration, Soundproofing Materials, Safety Products

- Fasteners

- Materials

- Wiring Components

- LAN Cables / Industrial Network Cables

- Equipment Specific Cables

- Cordsets

- Computer & AV Cables

- Wire/Cable

- Connector (General Purpose)

- Crimp Terminal Components

- Cable Organization

- Cable Gland Components

- Cable Bushing/Clip/Sticker

- Screw/Spacer

- Cable accessories

- Tube

- Electrical Conduits

- Duct/Wiring

- Electrical Wiring Tools

- Dedicated tools

- Soldering supplies

- Electrical & Controls

- Cutting Tools

- Carbide End Mill

- HSS End Mill

- Concrete Drill Bits

- Milling Cutter Insert / Holder

- Core Drill Bits

- Customized Straight Blade End Mill

- Dedicated Cutter

- Crinkey Cutters

- Turning Tool

- Drill

- Cutting Tool Accessories

- Screw Hole Related Tools

- Reamer

- Electric Drill Bits

- Chamfering, Centering Tool

- Hole Saws

- Magnetic Drill Press Cutters

- Step Drills

- Wood Drills & Cutters

- Processing Tools

- packing & logistics storage supplies

- Safety Products

- research and development & cleanroom supplies

- Press Die Components

- Plastic Mold Components

- Ejector Pins

- Sleeves, Center Pins

- Core Pins

- Sprue bushings, Gates, and other components

- Date Mark Inserts, Recycle Mark Inserts, Pins with Gas Vent

- Undercut, Plates

- Leader Components, Components for Ejector Space

- Mold Opening Controllers

- Cooling or Heating Components

- Accessories, Others

- Components of Large Mold, Die Casting

- Injection Molding Components

- Purging Agent

- Injection Molding Machine Products

- Accessories of Equipment

- Auxiliary Equipment

- Air Nippers

- Air Cylinders

- Air Chuck for Runner

- Chuck Board Components

- Frames

- Suction Components

- Parallel Air Chuck

- Special Air Chuck

- Mold Maintenance

- Heating Items

- Heat Insulation Sheets

- Couplers, Plugs, One-touch Joints

- Tubes, Hoses, Peripheral Components

Applications

Brands

- Webcode Seach | Series

-

#CODE

- Discontinued Products

Linear Ball Bushings - Flanged, double, with MX lubrication unit.

- Volume Discount

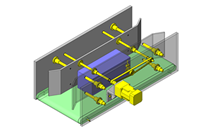

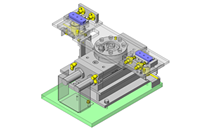

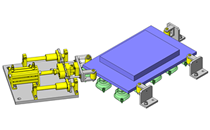

Automatic Lubricateion drastically decreases Maintenance Frequency Maintenance Cost Reduction Realizable Product

- METRIC

- inCAD Components

Part Number

Configured Part Number is shown.

| Type | Outer Cylinder | Balls | Pad Case / Retainer | Ambient Operating Temp. | [ A ]Accessories | ||||

| Round Flanged | Square Flanged | Compact Flanged | [ M ]Material | [ H ]Hardness | [ S ] | [ M ]Material | [ M ]Material | ||

| LHFRW-MX | LHFSW-MX | LHFCW-MX | 52100 Bearing Steel | 58HRC~ | - | 52100 Bearing Steel | Plastic (Duracon M90) | -20~80°C | Seal[ M ]Material Nitrile Rubber |

| LHFRWM-MX | LHFSWM-MX | LHFCWM-MX | Electroless Nickel Plating | 440C Stainless Steel | |||||

Specifications

| Part Number | |

| LHFRW-MX16 LHMSW-MX20 | |

| Part Number | D Tolerance | L | L1 | V | H | T | d | d1 | t | P.C.D. | W | F | A | Eccentricity | Rows of Balls | *Perpendicularity | Basic Load Rating | Allowable Static Moment (MoN·m) | Mass (g) | ||||||||

| Type | dr | Tolerance | No Surface Treatment | Surface Treatment | Tolerance | C (Dynamic) N | Co (Static) N | Round Flange | Square Flange | Compact Flange | |||||||||||||||||

| LHFRW-MX LHFSW-MX LHFCW-MX LHFRWM-MX LHFSWM-MX LHFCWM-MX | 10 | 0 - 0.010 | 19 | 0 - 0.016 | 0 - 0.021 | 65 | 55 | ±0.3 | 5 | 40 | 6 | 4.5 | 7.5 | 4.1 | 29 | 30 | - | 29 | 0.015 | 4 | 0.015 | 588 | 1100 | 7.24 | 102 | 82 | 94 |

| 12 | 21 | 68 | 57 | 5.5 | 42 | 32 | 32 | - | 32 | 657 | 1200 | 10.9 | 114 | 94 | 106 | ||||||||||||

| 16 | 28 | 82 | 70 | 6 | 48 | 38 | 37 | 22 | 31 | 1230 | 2350 | 19.7 | 197 | 172 | 189 | ||||||||||||

| 20 | 0 - 0.012 | 32 | 0 - 0.019 | 0 - 0.025 | 94 | 80 | 7 | 54 | 8 | 5.5 | 9 | 5.1 | 43 | 42 | 24 | 36 | 0.020 | 5 | 0.020 | 1400 | 2740 | 26.8 | 271 | 236 | 258 | ||

| 25 | 40 | 130 | 112 | 9 | 62 | 51 | 50 | 32 | 40 | 6 | 1560 | 3140 | 43.4 | 559 | 519 | 544 | |||||||||||

| 30 | 45 | 143 | 123 | 10 | 74 | 10 | 6.6 | 11 | 6.1 | 60 | 58 | 35 | 49 | 2490 | 5490 | 82.8 | 704 | 614 | 669 | ||||||||

| 35 | 0 - 0.015 | 52 | 0 -0.022 | 0 - 0.030 | 157 | 135 | 11 | 82 | 67 | 64 | 38 | 55 | 0.025 | 0.025 | 2650 | 6270 | 110 | 1048 | 958 | 973 | |||||||

| 40 | 60 | 175 | 151 | 12 | 96 | 13 | 9 | 14 | 8.1 | 78 | 75 | 45 | 64 | 3430 | 8040 | 147 | 1603 | 1413 | 1456 | ||||||||

| 50 | 80 | 220 | 192 | 14 | 116 | 98 | 92 | 56 | 80 | 6080 | 15900 | 397 | 3663 | 3463 | 3500 | ||||||||||||

[ ! ]For Precautions for Use, see >> Click here [ ! ]Height-Adjusting Spacers for Flanged Bushings can be chosen from >> Click here * Perpendicularity of D to flange mounting surface

Price list

| dr | Flanged, Double | Center Flanged Double | ||||||||||||||||

| Round Flange | Square Flange | Compact Flange | Round Flange | Square Flange | Compact Flange | |||||||||||||

| LHFRW-MX | LHFRWM-MX | LHFSW-MX | LHFSWM-MX | LHFCW-MX | LHFCWM-MX | LHMRW-MX | LHMSW-MX | LHMCW-MX | ||||||||||

| Unit Price | Volume Discount Rate | Unit Price | Volume Discount Rate | Unit Price | Volume Discount Rate | Unit Price | Volume Discount Rate | Unit Price | Volume Discount Rate | Unit Price | Volume Discount Rate | Unit Price | Volume Discount Rate | Unit Price | Volume Discount Rate | Unit Price | Volume Discount Rate | |

| 1~9 pc(s). | 10~19 pcs. | 1~9 pc(s). | 10~19 pcs. | 1~9 pc(s). | 10~19 pcs. | 1~9 pc(s). | 10~19 pcs. | 1~9 pc(s). | 10~19 pcs. | 1~9 pc(s). | 10~19 pcs. | 1~9 pc(s). | 10~19 pcs. | 1~9 pc(s). | 10~19 pcs. | 1~9 pc(s). | 10~19 pcs. | |

| 10 | 1,270 | 1,200 | 1,650 | 1,560 | 1,490 | 1,410 | 1,940 | 1,840 | 1,300 | 1,230 | 1,690 | 1,600 | 1,490 | 1,410 | 1,720 | 1,630 | 1,520 | 1,440 |

| 12 | 1,350 | 1,280 | 1,760 | 1,670 | 1,580 | 1,500 | 2,070 | 1,960 | 1,370 | 1,300 | 1,790 | 1,700 | 1,580 | 1,500 | 1,850 | 1,750 | 1,610 | 1,520 |

| 16 | 1,710 | 1,620 | 2,240 | 2,120 | 2,000 | 1,900 | 2,620 | 2,480 | 1,710 | 1,620 | 2,250 | 2,130 | 2,000 | 1,900 | 2,340 | 2,220 | 2,010 | 1,900 |

| 20 | 2,080 | 1,970 | 2,700 | 2,560 | 2,420 | 2,290 | 3,160 | 3,000 | 2,090 | 1,980 | 2,710 | 2,570 | 2,420 | 2,290 | 2,830 | 2,680 | 2,430 | 2,300 |

| 25 | 2,980 | 2,830 | 3,880 | 3,680 | 3,470 | 3,290 | 4,540 | 4,310 | 2,990 | 2,840 | 3,890 | 3,690 | 3,470 | 3,290 | 4,070 | 3,860 | 3,480 | 3,300 |

| 30 | 4,110 | 3,900 | 5,350 | 5,080 | 4,790 | 4,550 | 6,290 | 5,970 | 4,120 | 3,910 | 5,360 | 5,090 | 4,800 | 4,560 | 5,630 | 5,340 | 4,810 | 4,560 |

| 35 | 6,830 | 6,480 | 7,910 | 7,510 | 8,020 | 7,610 | 9,100 | 8,640 | 7,190 | 6,830 | 8,350 | 7,930 | 8,050 | 7,640 | 9,470 | 8,990 | 8,290 | 7,870 |

| 40 | 8,710 | 8,270 | 10,290 | 9,770 | 10,260 | 9,740 | 11,830 | 11,230 | 9,180 | 8,720 | 10,860 | 10,310 | 10,260 | 9,740 | 12,140 | 11,530 | 10,570 | 10,040 |

| 50 | 11,640 | 11,050 | 14,590 | 13,860 | 13,720 | 13,030 | 16,680 | 15,840 | 12,290 | 11,670 | 15,420 | 14,640 | 13,730 | 13,040 | 16,240 | 15,420 | 14,170 | 13,460 |

Part Number

CAD Data download and 3D preview are not available because the part number has not yet been determined.

- *In order to open the CAD Data download and 3D preview screen, the part number must be fixed.

- Please confirm the part number from "Specification / Dimension"on the left side, and then perform the CAD Data Download / 3D Preview operation.

Loading...

Support Information

Reference: Tolerance Range of Linear Bushing and Shafts made by MISUMI

For MISUMI Linear Bushing, it is recommended to use the combination with MISUMI Shafts (hardened to g6 tolerance).

| H6 | H7 | H8 | H9 | Applicable Part | Functional Classification | Application Example | ||||

|---|---|---|---|---|---|---|---|---|---|---|

| Can be Moved Relatively | Clearance Fit | Roll Fit | f6 | f7 | f7 f8 | Fitted to provide adequate clearance to permit movement (high quality fit). Regular normal temperature bearing lubricated with grease or oil. | Regular Fitting (Often comes apart.) | Part into which a cooled exhaust valve box is inserted. Regular Shaft and Bushing Link lever and bushing | ||

| Fine Roll Fit | g5 | g6 | Continuously revolving part of a precision machine under a light load. Fitting with a narrow gap so as to permit movement (spigot and positioning). Precision sliding part. | Part required for precise motion with virtually no backlash. | Link Device Pin and Lever Key and its groove Precision control valve rod | |||||

| Cannot be Moved Relatively | Transition Fit | Sliding Fit | h5 | h6 | h7 h8 | h9 | Fitting so as to permit movement by hand, with a lubricant applied (high-quality positioning). Special High Precision Sliding Part Unimportant Stationary Part | Can be disassembled and reassembled without damaging components. | Force cannot be transmitted by the fitting force alone. | Fitting a rim and a boss together Fitting the gear of a precision gear device |

| Push Fit | h5 h6 | js6 | Fitting that accommodates a slight gap. Precision fitting that locks both parts during use. Fitting that allows assembly and disassembly with a wooden or lead hammer. | Fitting Coupling Flanges Together Governor Path and Pin Fitting a Gear Rim and a Boss Together | ||||||

Features

MX Lubrication Unit

Lubrication Unit MX has a fiber pad that contains the lubricant. The capillary action allows the lubricant to reach the mating surfaces.

As a result, an oil film is always formed between the balls and the shaft, significantly extending service intervals.

If an unbalanced load is applied due to the deflection of the handles to one side of the slide guide, the phenomenon of "Ball Retainer Misalignment" may occur.

Keep this in mind when designing.

Endurance Test Result

Test Conditions

Product:

LMU12 (Linear bushing before removing the oil protection against rust.)

LMU-MX12 (Linear bushing with lubrication unit MX)

Applied Load: 206N (50% against Basic Dynamic Load Rating 412N)

Average Speed: 42 m/min (0.7 m/sec)

Stroke : 100 mm

Lubricant: Grease, initial fill (LMU-MX12 only)

Shaft Material: 52100 Bearing steel 58 HRC

24 hours, continuously operated.

With 50% of basic load rating applied for testing, the Lubrication Unit MX Type has shown a 2.5 times higherdurability performance compared to the one without the MX lubrication unit.

*The data shown above are for reference only, and are not guaranteed by the supplier

Characteristics

Extended Maintenance Period:

Long durability of lubrication performance have resulted in significant reduction of maintenance work especially with machines and equipment environments where applying grease is not easy.

Environmentally friendly system:

Proper amount of lubricant to ball rolling surface at right time makes the system environment-friendly.

Cost Advantage:

Contributes to reduction of maintenance costs and product troubles caused by failing to lubricate.

Reduced Procedural Steps

No need to fill with grease prior to use because the product is already filled with Lithium soap-based grease in addition to the built-in lubrication unit.

Way to Use

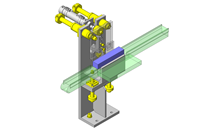

Mounting Considerations

– When mounting the flanged type bushing with MX lubrication unit, do not use the lubrication housing as a pilot as shown in (2), because it may damage the housing. Instead, use the Flanged Type with Pilot as shown in (3).

– Do not disassemble the lubrication unit as this may cause failure or shorten the life of the product.

Flanged Type

(Correct Mounting)

Flange Type

(Incorrect Mounting)

Flanged Type with Pilot

(Correct Mounting)

Features

Linear bushings compatible with low-temperature black chrome plating

*The photo shows the condition of the shafts & linear bushings after the sliding test.

ー Low-temperature black chrome plating on linear bushings is a 5µm fluoropolymer layer chemically deposited as a black film, and it has a long-lasting rust preventive effect.

In addition, the coating is resistant to cracking from extreme and repeated bending.

ー Low-temperature black chrome-plated shafts are suitable for locations where rusting or light reflection is undesirable.

ーWhen used as an assembly with a linear shaft that is compatible with low-temperature black chromium plating, it is suitable for rust prone locations.

Note: The bore of the low-temperature chromium-plated Linear Bearing has no surface treatment.

Sliding Test Conditions

50 km sliding test was conducted with a 412 N load on the linear bushing.

No performance degradation after testing.

Linear bushing model compatible with low temperature black chrome plating.

| Straight Type | Compatible Inner Diameter | |

|---|---|---|

| Single Type | Φ3~φ30 |

| Double Type | Φ5~φ30 |

| Flange Type | Compatible Inner Diameter | |

| Single Type | Φ6~φ30 |

| Double Type | |

MISUMI linear bushings, with the exception of the MX type lubrication unit, are coated with anti-rust oil, but not with grease. By selecting the grease below, you can switch to one with grease application.

Antirust Performance Comparison Test (Reference)

| 52100 Bearing Steel | 440C Stainless Steel | Electroless Nickel Plating | Low Temperature Black Chrome Plating | |

|---|---|---|---|---|

| Before the test |  |  |  |  |

| 72 hrs |  |  |  |  |

| 168 hrs |  |  |  |  |

|  |  |  |

Test Method: Salt water spray testing method conforms to JIS H8502.

(Spray 35°C, 5% NaCl Solution)

Test Sample: Round Flanged Linear Bushings – Single Type

Compatible Models

Basic Information

| TYPE | Flange | Motion | Linear Motion | Style | Standard |

|---|---|---|---|---|---|

| Outer Cylinder Material | 52100 Bearing Steel Equivalent | Flange Type | Standard Flange | Lubrication Type | with MX Lubrication Unit |

| Type | Standard Flange | Ball Recirculating Type | Double | Precision | High Grade |

| Retainer Material | Plastic (Duracon M90 Equivalent) | Seals | With Seal | Counterbored Hole | Standard |

| Greased filled | Lithium Soap Base |

Specification/Dimensions

-

For Shaft Size(mm)

-

Overall Length L(mm)

-

O.D. D(mm)

-

Eccentricity(µm)

-

Flange Shape

- Compact Flanged

- Round Flanged

- Square Flanged

-

Ball Material

- 440C Stainless Steel Equivalent

- 52100 Bearing Steel Equivalent

-

type

- LHFCW-MX

- LHFCWM-MX

- LHFRW-MX

- LHFRWM-MX

- LHFSW-MX

- LHFSWM-MX

-

Outer Cylinder Surface Finish

- None

- Plated

-

CAD

- 2D

- 3D

Days to Ship

-

- All

- 8 Days or Less

Specify Alterations

- The specifications and dimensions of some parts may not be fully covered. For exact details, refer to manufacturer catalogs .

Additional Products in this Category

- Linear Ball Bushings - Center flange, double compact, reamed mounting holes.

- Linear Ball Bushings - With pilot flange, double (Inches).

- Linear Ball Bushings - Single. LME Series.

- Linear Ball Bushings - With square flange, long. LMK-L Series.

- Linear Ball Bushings - Linear/Rotating, single, with seals. Series ST-UU, ST-UUB.

- Linear Ball Bushings - Miniature, single. LMS Series.

- Linear Ball Bushings - Compact, single bearing type. CH Series.

- Linear Ball Bushings - Compact, double bearing type. CHW Series.

Complementary Products

Tech Support

- Technical Support

- Tel:+52-442-672-7661 ext. 2 then wait and dial 4

E-mail: soportetecnico@misumimex.com - Mon. - Fri. 8 a.m. - 6 p.m.

- Technical Inquiry

How can we improve?

How can we improve?

While we are not able to respond directly to comments submitted in this form, the information will be reviewed for future improvement.

Customer Privacy Policy

Thank you for your cooperation.

While we are not able to respond directly to comments submitted in this form, the information will be reviewed for future improvement.

Please use the inquiry form.

Customer Privacy Policy