(!)Due to Microsoft's end of support for Internet Explorer 11 on 15/06/2022, this site does not support the recommended environment.

Mon. - Fri. 8 a.m. - 6 p.m.

All Categories

-

Automation Components

Automation Components

Show all categories of Automation Components-

Linear Motion

-

Rotary Motion

-

Connecting Parts

-

Rotary Power Transmission

-

Motors

-

Conveyors & Material Handling

-

Locating, Positioning, Jigs & Fixtures

-

Inspection

-

Sensors, Switches

-

Pneumatics, Hydraulics

-

Vacuum Components

-

Hydraulic Equipment

-

Spray Equipment And Accessories

-

Pipe, Tubes, Hoses & Fittings

-

Modules, Units

-

Heaters, Temperature Control

-

Aluminum Extrusions, Framing, Support & Posts

-

Casters, Leveling Mounts, Posts

-

Doors, Cabinet Hardware

-

Springs, Shock Absorbers

-

Adjustment/Fastening Components, Pins, Magnets

-

Antivibration, Soundproofing Materials, Safety Products

-

- Fasteners

- Materials

-

Wiring Components

Wiring Components

Show all categories of Wiring Components-

LAN Cables / Industrial Network Cables

-

Equipment Specific Cables

-

Cordsets

-

Computer & AV Cables

-

Wire/Cable

-

Connector (General Purpose)

-

Crimp Terminal Components

-

Cable Organization

-

Cable Gland Components

-

Cable Bushing/Clip/Sticker

-

Screw/Spacer

-

Cable accessories

-

Tube

-

Electrical Conduits

-

Duct/Wiring

-

Electrical Wiring Tools

-

Dedicated tools

-

Soldering supplies

-

- Electrical & Controls

-

Cutting Tools

Cutting Tools

Show all categories of Cutting Tools-

Carbide End Mill

-

HSS End Mill

-

Concrete Drill Bits

-

Milling Cutter Insert / Holder

-

Core Drill Bits

-

Customized Straight Blade End Mill

-

Dedicated Cutter

-

Crinkey Cutters

-

Turning Tool

-

Drill

-

Cutting Tool Accessories

-

Screw Hole Related Tools

-

Reamer

-

Electric Drill Bits

-

Chamfering, Centering Tool

-

Hole Saws

-

Magnetic Drill Press Cutters

-

Step Drills

-

Wood Drills & Cutters

-

-

Processing Tools

- Packing & Logistics Storage Supplies

- Safety Products

-

Research and Development & Cleanroom Supplies

Research and Development & Cleanroom Supplies

Show all categories of Research and Development & Cleanroom Supplies - Press Die Components

-

Plastic Mold Components

Plastic Mold Components

Show all categories of Plastic Mold Components-

Ejector Pins

-

Sleeves, Center Pins

-

Core Pins

-

Sprue bushings, Gates, and other components

-

Date Mark Inserts, Recycle Mark Inserts, Pins with Gas Vent

-

Undercut, Plates

-

Leader Components, Components for Ejector Space

-

Mold Opening Controllers

-

Cooling or Heating Components

-

Accessories, Others

-

Components of Large Mold, Die Casting

-

-

Injection Molding Components

Injection Molding Components

Show all categories of Injection Molding Components-

Purging Agent

-

Injection Molding Machine Products

-

Accessories of Equipment

-

Auxiliary Equipment

-

Air Nippers

-

Air Cylinders

-

Air Chuck for Runner

-

Chuck Board Components

-

Frames

-

Suction Components

-

Parallel Air Chuck

-

Special Air Chuck

-

Mold Maintenance

-

Heating Items

-

Heat Insulation Sheets

-

Couplers, Plugs, One-touch Joints

-

Tubes, Hoses, Peripheral Components

-

- Webcode Seach | Series

-

#CODE

- Discontinued Products

Loading...

- inCAD Library Home

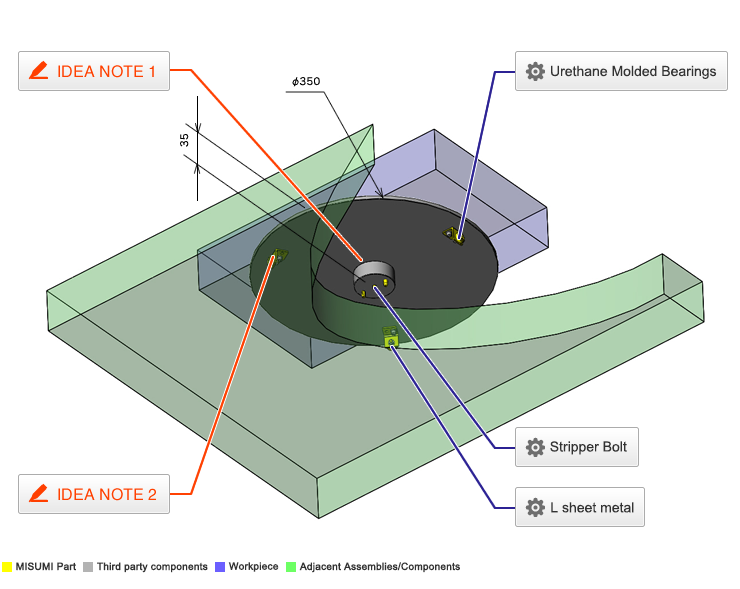

- > No.000183 Removable Turntable

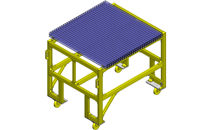

No.000183 Removable Turntable

Bottom view of removable turntable.

Relevant category

- * Unit assembly Data consists of some sub-assemblies.

It is configured so that each sub-assembly unit can be used as it is or edited.

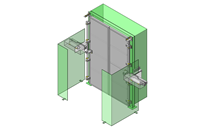

Application Overview

Purpose

- Purpose

- Used for product inspection/repair.

- Operation

- Product inspection and repair are conducted on a workbench. If the turntable is not needed, it is removable by loosening center turntable bolt. When re-installing, use the two center locating pins to position the table and tightening the center bolt.

Points for use

- The turntable is rotated manually.

Target workpiece

- Shape: Block

- Size: W 430 x D 250 x H 70 mm

- Weight: 6 kg

Design Specifications

Operating Conditions or Design Requirements

- Turntable O.D.: φ350mm

- External size (workbench): W 700 x D 600 x H 170 mm

Selection Criteria for Main Components

- Select size for urethane molded bearings to support motions and to prevent deflection of the turntable.

Design Evaluation

Verification of main components

- Verify bearing durability or life span based on load rating.

- Calculate life span of the bearing

- Life span for bearings (106 rotations): L = (Cr/Pr)³ , where

Cr=7250N - Basic Dynamic load rating for B6906ZZ (from catalog)

Pr- Radial Dynamic Equivalent load (need to calculate based on application loads) - Other conditionals values:

Workpiece weight: M = 6 kg

Gravitational acceleration: g = 9.8 m/s²

Gravity by the workpiece: W = M x g = 6 x 9.8 = 59 N

Manual force used to move turntable: Assume to be Q = 200 N - Radial Dynamic Equivalent load

Pr =X×Fr + Y×Fa, where Fr-radial load, Fa-thrust load and X=1 and Y=2.3 are radial and thrust factor (values from catalog) - Assume that force acting on the bearing, Po = M + Q, acts only in the z-axis direction (thrust load), and let radial load Fr=0N, then we obtain the following:

Thrust load: Fa=Po=M+Q=259N、then

Pr=1×Fr+2.3×(M+Q)=1×0+2.3×259=596N - Bearing rated life L = (Cr/Pr)³ = (7250/596)³ = 1800 (10? rotations), has sufficient margin for our application.

- Life span for bearings (106 rotations): L = (Cr/Pr)³ , where

Other Design Consideration

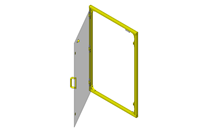

- Securing repeatability of the turntable position and fixing the turntable with one bolt.

- In this example two round locating pins are used for turntable positioning, combination of round and diamond pin can also be effectively used.

Explore Similar Application Examples

-

Relevant category

-

Relevant category