(!)Due to Microsoft's end of support for Internet Explorer 11 on 15/06/2022, this site does not support the recommended environment.

Mon. - Fri. 8 a.m. - 6 p.m.

All Categories

Categories

- Automation Components

- Linear Motion

- Rotary Motion

- Connecting Parts

- Rotary Power Transmission

- Motors

- Conveyors & Material Handling

- Locating, Positioning, Jigs & Fixtures

- Inspection

- Sensors, Switches

- Pneumatics, Hydraulics

- Vacuum Components

- Hydraulic Equipment

- Spray Equipment And Accessories

- Pipe, Tubes, Hoses & Fittings

- Modules, Units

- Heaters, Temperature Control

- Aluminum Extrusions, Framing, Support & Posts

- Casters, Leveling Mounts, Posts

- Doors, Cabinet Hardware

- Springs, Shock Absorbers

- Adjustment/Fastening Components, Pins, Magnets

- Antivibration, Soundproofing Materials, Safety Products

- Fasteners

- Materials

- Wiring Components

- LAN Cables / Industrial Network Cables

- Equipment Specific Cables

- Cordsets

- Computer & AV Cables

- Wire/Cable

- Connector (General Purpose)

- Crimp Terminal Components

- Cable Organization

- Cable Gland Components

- Cable Bushing/Clip/Sticker

- Screw/Spacer

- Cable accessories

- Tube

- Electrical Conduits

- Duct/Wiring

- Electrical Wiring Tools

- Dedicated tools

- Soldering supplies

- Electrical & Controls

- Cutting Tools

- Carbide End Mill

- HSS End Mill

- Concrete Drill Bits

- Milling Cutter Insert / Holder

- Core Drill Bits

- Customized Straight Blade End Mill

- Dedicated Cutter

- Crinkey Cutters

- Turning Tool

- Drill

- Cutting Tool Accessories

- Screw Hole Related Tools

- Reamer

- Electric Drill Bits

- Chamfering, Centering Tool

- Hole Saws

- Magnetic Drill Press Cutters

- Step Drills

- Wood Drills & Cutters

- Processing Tools

- packing & logistics storage supplies

- Safety Products

- research and development & cleanroom supplies

- Press Die Components

- Plastic Mold Components

- Ejector Pins

- Sleeves, Center Pins

- Core Pins

- Sprue bushings, Gates, and other components

- Date Mark Inserts, Recycle Mark Inserts, Pins with Gas Vent

- Undercut, Plates

- Leader Components, Components for Ejector Space

- Mold Opening Controllers

- Cooling or Heating Components

- Accessories, Others

- Components of Large Mold, Die Casting

- Injection Molding Components

- Purging Agent

- Injection Molding Machine Products

- Accessories of Equipment

- Auxiliary Equipment

- Air Nippers

- Air Cylinders

- Air Chuck for Runner

- Chuck Board Components

- Frames

- Suction Components

- Parallel Air Chuck

- Special Air Chuck

- Mold Maintenance

- Heating Items

- Heat Insulation Sheets

- Couplers, Plugs, One-touch Joints

- Tubes, Hoses, Peripheral Components

Applications

Brands

- Webcode Seach | Series

-

#CODE

- Discontinued Products

Tubes & Tube Accessories(Operating Environment:Oil Resistance Page2)

| Days to Ship |

|

|---|

-

Tubing - PFA, Junflon Tube, TA Series

Junkosha

Excels in heat resistance and cold resistance. Inactive against most of chemicals and solvents. Highly weather resistant and does not deteriorate with time. Things are less likely to adhere on it, and will be easier to remove if they do.

Days to Ship: 13 Days or more -

Tubing - Nylon, Soft, Junron A, Control Tube, AC1 Series

Junkosha

Mechanical strength, in particular pressure resistance, wear resistance, flexural fatigue resistance is excellent. Excels in heat and low temperature resistance. High flexibility. Excels in oil resistance and chemical resistance (especially alkaline resistance). No risk of toxic substances being released.

- Volume Discount

Days to Ship: 14 Days or more -

Tubing - Nylon, Soft, Junron A, AS1 Series, Inch

Junkosha

Excellent mechanical strength, as well as pressure, wear resistance, and flexural fatigue resistance. Excels in heat and low temperature resistance. High flexibility. Excels in oil and chemical resistance (especially alkaline resistance). No risk of toxic substances being released.

- Volume Discount

Days to Ship: 8 Days or more -

Tubing - Nylon, Soft, Junron A, AS1 Series, Metric

Junkosha

[Features]

· Excellent mechanical strengths (especially, pressure resistance, wear resistance and bending fatigue tolerance).

· Product has superior low temperature and heat resistance properties.

· Highly flexible.

· Product has superior oil resistance and chemical resistance properties (especially alkali resistance).

▪ No risk of toxic substances being released.

▪ It is light in weight and has excellent workability- Volume Discount

Days to Ship: 8 Days or more -

Tubing - Nylon, Junron A, High-Pressure, AS2 Series

Junkosha

[Features]

· Excellent mechanical strength (pressure resistance, wear resistance, and bending fatigue tolerance).

· Highly flexible.

· Superior cold- and heat-resistance properties.

· Temperature range of resin for continuous operation without load: -40° to 93℃ with high flexibility.

· The product is highly oil and chemical resistant (displays high alkaline resistance in particular).

· No risk of poisonous substances being released.

· Lightweight and workable.- Volume Discount

Days to Ship: 8 Days or more -

Tubing - Nylon, Super-Soft, Junron A, AS4 Series

Junkosha

[Features]

· Excellent mechanical strength (pressure resistance, wear resistance, and bending fatigue tolerance).

· Highly flexible.

· Superior cold- and heat-resistance properties.

· Temperature range of resin for continuous operation without load: -40° to 93℃ with high flexibility.

· The product is highly oil and chemical resistant (displays high alkaline resistance in particular).

· No risk of poisonous substances being released.

· Lightweight and workable.Days to Ship: 12 Days or more -

Tubing - Fluoropolymer, Junron Hybrid, AP1 Series

Junkosha

The two-layer structure achieves higher levels of flexibility, kink resistance and wear resistance. Fluoride polymer for the inner layer provides superior repelling power against liquid chemicals. Layers are fully adhered because it is integrally molded.

- Volume Discount

Days to Ship: 12 Days or more -

Tubing - Fluoropolymer, UP1 Series

Junkosha

The 2-layer structure achieves higher levels of flexibility, kink resistance and wear resistance. Fluoride polymer for the inner layer provides superior repelling power against liquid chemicals. Layers are fully adhered because it uses integral molded.

- Volume Discount

Days to Ship: 12 Days or more -

Tubing - PTFE, Ultra Chemical-Resistant

USA Industrials

PTFE has superior chemical and heat resistance over other plastic and rubber tubing materials, and withstands steam for sterilization.

Days to Ship: Quote -

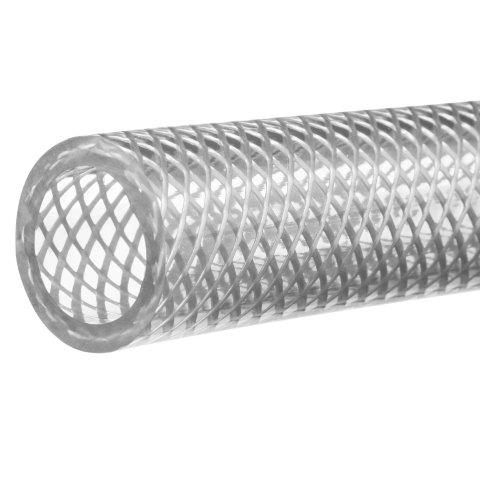

Tubing - PVC, Multipurpose, 3-A Sanitary Standards Compliant, Polyester Braid Reinforced

USA Industrials

This high purity PVC tubing is made of FDA compliant materials and certified to 3A standards for food, beverage, dairy, and pharmaceutical applications. It is colorless and clear to easily observe flow. It is also reinforced with a polyester braid to withstand higher pressures. PVC is used for general purposes and can withstand a wide range of chemicals.

Days to Ship: Quote -

Tubing - PVC, Multipurpose, 3-A Sanitary Standards Compliant

USA Industrials

This high purity PVC tubing is made of FDA compliant materials and certified to 3A standards for food, beverage, dairy, and pharmaceutical applications. It is colorless and clear to easily observe flow. PVC is used for general purposes and can withstand a wide range of chemicals

Days to Ship: Quote -

Tubing - PVC, Multipurpose, FDA Compliant, Steel Wire Reinforced

USA Industrials

This PVC is reinforced with steel wire to withstand higher pressures and reduce the buildup of static electricity. PVC is used for general purposes and can withstand a wide range of chemicals.

Days to Ship: Quote

| Brand |

|---|

| Product Series |

| CAD |

| Days to Ship |

| Type |

| Material |

| Cutting Service Usage |

| Color |

| O.D. [Distinction] |

| Applicable Fluid |

| O.D. D(Ø) |

| I.D. [Distinction] |

| I.D. d(Ø) |

| Number of Bores(per piece) |

| Material, Urethane |

| Material: Nylon |

| Material, Fluororesin |

| Operating Environment |

| O.D. (2nd Core) |

| O.D. (3rd Core) |

| O.D. (4th Core) |

| I.D. (2nd Core) |

| I.D. (3rd Core) |

| I.D. (4th Core) |

| Types of Related components |

| Brand | Junkosha | Junkosha | Junkosha | Junkosha | Junkosha | Junkosha | Junkosha | Junkosha | USA Industrials | USA Industrials | USA Industrials | USA Industrials |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Product Series | Tubing - PVC, Multipurpose, 3-A Sanitary Standards Compliant, Polyester Braid Reinforced | Tubing - PVC, Multipurpose, 3-A Sanitary Standards Compliant | Tubing - PVC, Multipurpose, FDA Compliant, Steel Wire Reinforced | |||||||||

| CAD | ||||||||||||

| Days to Ship | 13 Days or more | 14 Days or more | 8 Days or more | 8 Days or more | 8 Days or more | 12 Days or more | 12 Days or more | 12 Days or more | Quote | Quote | Quote | Quote |

| Type | Straight | Straight | Straight | Straight | Straight | Straight | Straight | Straight | - | - | - | - |

| Material | Fluororesin | Nylon | Nylon | Nylon | Nylon | Nylon | Fluororesin | Fluororesin | Fluororesin | PVC | PVC | PVC |

| Cutting Service Usage | - | - | - | - | - | - | - | - | - | - | - | - |

| Color | Others | Black | Black / Translucent White | Black / Translucent White / Red / Blue / Yellow / Green | Translucent White | Black / Translucent White | Translucent White | Translucent White | Translucent White | White / Transparent (including non-white colors) / Gray | Transparent (including non-white colors) | Transparent (including non-white colors) |

| O.D. [Distinction] | ~10 | ~6 | ~4 ~ ~15 | ~4 ~ ~20 | ~4 ~ ~15 | ~6 ~ ~10 | ~4 ~ ~10 | ~4 ~ ~15 | - | - | - | - |

| Applicable Fluid | Water / Air / Chemical / General Hydraulic Oil | Water / Air / General Hydraulic Oil | Water / Air / General Hydraulic Oil | Water / Air / General Hydraulic Oil | Water / Air / General Hydraulic Oil | Water / Air / General Hydraulic Oil | Water / Air / General Hydraulic Oil | Water / Air / General Hydraulic Oil | Water / Air / Chemical / General Hydraulic Oil / Thermal Media Oil | Water / Air / Chemical / General Hydraulic Oil / Thermal Media Oil | Water / Air / Chemical / General Hydraulic Oil / Thermal Media Oil | Water / Air / Chemical / General Hydraulic Oil / Thermal Media Oil |

| O.D. D(Ø) | 10 | 6 | 3.18 ~ 12.7 | 4 ~ 16 | 4 ~ 12 | 6 ~ 10 | 4 ~ 10 | 4 ~ 12 | 0.090" ~ 16 | 1" ~ 48 | 1" ~ 24 | 1" ~ 9/16" |

| I.D. [Distinction] | ~8 | ~4 | ~3 ~ ~10 | ~3 ~ ~15 | ~3 ~ ~9 | ~4 ~ ~8 | ~3 ~ ~8 | ~3 ~ ~8 | - | - | - | - |

| I.D. d(Ø) | 8 | 4 | 2.36 ~ 9.56 | 2.5 ~ 13 | 2.5 ~ 9 | 4 ~ 7.5 | 2.5 ~ 8 | 2.5 ~ 8 | 0.066" ~ 12 | 1" ~ 38 | 1" ~ 15 | 1-1/2" ~ 5/16" |

| Number of Bores(per piece) | - | 1 ~ 12 | - | - | - | - | - | - | - | - | - | - |

| Material, Urethane | - | - | - | - | - | - | - | - | - | - | - | - |

| Material: Nylon | - | Soft Nylon | Soft Nylon | Soft Nylon | Pressure Resistant Nylon | Soft Nylon | - | - | - | - | - | - |

| Material, Fluororesin | Others | - | - | - | - | - | Others | Others | Standard Fluororesin | - | - | - |

| Operating Environment | Oil Resistance | Oil Resistance | Oil Resistance | Oil Resistance | Oil Resistance | Oil Resistance | Oil Resistance | Oil Resistance | Oil Resistance | Oil Resistance | Oil Resistance | Oil Resistance |

| O.D. (2nd Core) | - | - | - | - | - | - | - | - | - | - | - | - |

| O.D. (3rd Core) | - | - | - | - | - | - | - | - | - | - | - | - |

| O.D. (4th Core) | - | - | - | - | - | - | - | - | - | - | - | - |

| I.D. (2nd Core) | - | - | - | - | - | - | - | - | - | - | - | - |

| I.D. (3rd Core) | - | - | - | - | - | - | - | - | - | - | - | - |

| I.D. (4th Core) | - | - | - | - | - | - | - | - | - | - | - | - |

| Types of Related components | - | - | - | - | - | - | - | - | - | - | - | - |

Loading...

Configure

Stock

-

- Show Stock Products

Specification/Dimensions

-

Type

-

Material

- Urethane

- Nylon

- Fluororesin

- Polyamide

- Fluororubber

- Silicon Rubber

- Polyolefin Resin

- Others

- PVC

- Polypropylene

-

Cutting Service Usage

- Yes

- No

-

Color

- Black

- White

- Translucent White

- Transparent (including non-white colors)

- Red

- Blue

- Yellow

- Green

- Orange

- Ocher

- Gray

- Multi Color

- Pink

- Others

- Brown

- Purple

- Silver

- Transparent Blue

-

O.D. [Distinction]

-

Applicable Fluid

- Water

- Air

- Chemical

- General Hydraulic Oil

- Thermal Media Oil

-

Metric / Inch

- metric

-

O.D. D(Ø)

- 0.090"

- 1/8"

- 5/32"

- 3/16"

- 0.205"

- 7/32"

- 1/4"

- 0.256"

- 5/16"

- 0.319"

- 3/8"

- 7/16"

- 0.441"

- 1/2"

- 17/32"

- 9/16"

- 0.579"

- 5/8"

- 11/16"

- 3/4"

- 13/16"

- 7/8"

- 1"

- 1-1/8"

- 1-1/4"

- 1-3/8"

- 1-1/2"

- 1-3/4"

- 2"

- 2-1/2"

- 3"

- 3-1/2"

- 1.6

- 1.7

- 1.8

- 10

- 10.2

- 10mm

- 11

- 11mm

- 12

- 12.2

- 12.5

- 12.7

- 12mm

- 13

- 13.5

- 13.5mm

- 13mm

- 14

- 14.2

- 14mm

- 15

- 16

- 16mm

- 17

- 18

- 18mm

- 2

- 2.5

- 20

- 22

- 23

- 24

- 25

- 25.4

- 26

- 28

- 29

- 3

- 3.17

- 3.18

- 3.2

- 3.5

- 34

- 35

- 4

- 4.5

- 4.76

- 42

- 47

- 48

- 4mm

- 5

- 5.95

- 52

- 57

- 5mm

- 6

- 6.35

- 62

- 7

- 7.6

- 7.85

- 7.94

- 7mm

- 8

- 8.2

- 8mm

- 9

- 9.53

- 9mm

-

I.D. [Distinction]

-

I.D. d(Ø)

-

Number of Bores(per piece)

-

Material, Urethane

-

Material: Nylon

-

Material, Fluororesin

-

Operating Environment

- Standard

- Clean Environment

- Corrosion Resistant

- Antistatic

- Sputter Resistant

- Mold Cooling

- Water Resistance

- Pressure Resistance

- For Vacuum

- Heat Resistance

- Abrasion Resistance

- Oil Resistance

- Low Temp. Resistance

- Weather Resistance

- Chemical Resistance

-

O.D. (2nd Core)

-

O.D. (3rd Core)

-

O.D. (4th Core)

-

I.D. (2nd Core)

-

I.D. (3rd Core)

-

I.D. (4th Core)

-

Types of Related components

Narrow search by specifying Manufacturer

-

- Chiyoda (27)

- USA Industrials (13)

- Junkosha (10)

- Nitta (2)

- Nihon Pisco (1)

- Miruc Optical (0)

- I.Field (0)

- Chukoh Chemical Industries (0)

- Trusco Nakayama (0)

- CKD (0)

- Nichias (0)

- Iwata Manufacturing (0)

- SMC (0)

- Muromoto (0)

CAD

-

- 2D

- 3D

Application example related to this category

Related Categories to Tubes & Tube Accessories

-

- Cylinders, Rotary Actuators

- Cylinder Connecting Components

- Filters, Regulators, Lubricators

- Solenoid Valves

- Dryers for Pneumatics

- Pneumatic Pipe Fittings

- Flow Controls & Throttle Valves

- Manual-Type Valves, Mechanical-Type Valves

- Pneumatic Pipe Fittings

- Pressure, Flow Rate Sensors

- Silencers

- Compressors, Blowers

- Solenoid Valves for Fluid & Air-Operated Valves

- Tubes & Tube Accessories

- Other Pneumatic Devices

-

How can we improve?

How can we improve?

While we are not able to respond directly to comments submitted in this form, the information will be reviewed for future improvement.

Customer Privacy Policy

Thank you for your cooperation.

While we are not able to respond directly to comments submitted in this form, the information will be reviewed for future improvement.

Please use the inquiry form.

Customer Privacy Policy