(!)Due to Microsoft's end of support for Internet Explorer 11 on 15/06/2022, this site does not support the recommended environment.

Mon. - Fri. 8 a.m. - 6 p.m.

All Categories

Categories

- Automation Components

- Linear Motion

- Rotary Motion

- Connecting Parts

- Rotary Power Transmission

- Motors

- Conveyors & Material Handling

- Locating, Positioning, Jigs & Fixtures

- Inspection

- Sensors, Switches

- Pneumatics, Hydraulics

- Vacuum Components

- Hydraulic Equipment

- Spray Equipment And Accessories

- Pipe, Tubes, Hoses & Fittings

- Modules, Units

- Heaters, Temperature Control

- Aluminum Extrusions, Framing, Support & Posts

- Casters, Leveling Mounts, Posts

- Doors, Cabinet Hardware

- Springs, Shock Absorbers

- Adjustment/Fastening Components, Pins, Magnets

- Antivibration, Soundproofing Materials, Safety Products

- Fasteners

- Materials

- Wiring Components

- LAN Cables / Industrial Network Cables

- Equipment Specific Cables

- Cordsets

- Computer & AV Cables

- Wire/Cable

- Connector (General Purpose)

- Crimp Terminal Components

- Cable Organization

- Cable Gland Components

- Cable Bushing/Clip/Sticker

- Screw/Spacer

- Cable accessories

- Tube

- Electrical Conduits

- Duct/Wiring

- Electrical Wiring Tools

- Dedicated tools

- Soldering supplies

- Electrical & Controls

- Cutting Tools

- Carbide End Mill

- HSS End Mill

- Concrete Drill Bits

- Milling Cutter Insert / Holder

- Core Drill Bits

- Customized Straight Blade End Mill

- Dedicated Cutter

- Crinkey Cutters

- Turning Tool

- Drill

- Cutting Tool Accessories

- Screw Hole Related Tools

- Reamer

- Electric Drill Bits

- Chamfering, Centering Tool

- Hole Saws

- Magnetic Drill Press Cutters

- Step Drills

- Wood Drills & Cutters

- Processing Tools

- packing & logistics storage supplies

- Safety Products

- research and development & cleanroom supplies

- Press Die Components

- Plastic Mold Components

- Ejector Pins

- Sleeves, Center Pins

- Core Pins

- Sprue bushings, Gates, and other components

- Date Mark Inserts, Recycle Mark Inserts, Pins with Gas Vent

- Undercut, Plates

- Leader Components, Components for Ejector Space

- Mold Opening Controllers

- Cooling or Heating Components

- Accessories, Others

- Components of Large Mold, Die Casting

- Injection Molding Components

- Purging Agent

- Injection Molding Machine Products

- Accessories of Equipment

- Auxiliary Equipment

- Air Nippers

- Air Cylinders

- Air Chuck for Runner

- Chuck Board Components

- Frames

- Suction Components

- Parallel Air Chuck

- Special Air Chuck

- Mold Maintenance

- Heating Items

- Heat Insulation Sheets

- Couplers, Plugs, One-touch Joints

- Tubes, Hoses, Peripheral Components

Applications

Brands

- Webcode Seach | Series

-

#CODE

- Discontinued Products

Flexible Shaft Couplings(Allowable Torque Range:0.05~1.00)

Type

-

With Slit

With Slit -

Disc Type

Disc Type -

Oldham Type

Oldham Type -

Jaw Type

Jaw Type -

Bellows Type

Bellows Type -

Others

Others

-

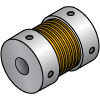

Flexible Couplings - Bellows type, miniature, zero backlash, MK2 series.

R+W

Features

Low restoring forces on coupled shafts

Easy installation

Light weight and low moment of inertia

Design

Two clamping hubs concentrically mounted to flexible bellows.

Material

Bellows: high grade stainless steel

Hubs: aluminum

Advantage

Precise and well-balanced transmission with zero backlash- CAD :

- 3D

Days to Ship: 5 Days or more -

Flexible Couplings - With rubber separator.

NBK

Flexible couplings with rubber separator. High vibration absorption. For high torque. Zero Backlash. Optimized for actuators.

- Volume Discount

Days to Ship: 8 Days or more Show Stock Products

-

Flexible Couplings - For servomotor.

NBK

Spider type flexible couplings, for servomotor. It has a separator that absorbs vibrations. Zero backlash. Excellent flexibility. 4 types of spacer hardnesses are selected depending on use, torque and misalignment.

- Volume Discount

Days to Ship: 8 Days or more -

Flexible Couplings - For high torque and vibration absorption.

MISUMI

Flexible spider couplings for high torque and vibration absorption. Zero backlash transmission is possible with low torque. Excellent flexibility and 4 types of spacer hardness.

- New Pricing

- METRIC

- inCAD Components

Days to Ship: 8 Days or more -

Flexible Couplings - Slotted type, standard length or compact.

MISUMI

Slotted type flexible couplings, with standard or compact length. The material can be selected between aluminum and stainless steel. The spring is completely integrated to the coupling body thanks to the grooves. Alterations are available to modify the dimension of the internal diameters.

- METRIC

- inCAD Components

Days to Ship: 8 Days or more -

Flexible Couplings - Standard torque disc, screw clamp type.

MISUMI

Flexible couplings, disc type, standard torque and screw clamp fixing. This type of coupling can be selected with one or two intermediate discs, and can also be selected with a wedge slot at either or both ends.

- METRIC

- inCAD Components

Days to Ship: 8 Days or more -

Flexible Couplings - Bellows type, selectable fastening type.

MISUMI

Flexible bellows-type couplings with selectable clamping type between clamping and clamping. Even if misalignment occurs, it can rotate at a constant speed.

- METRIC

- inCAD Components

Days to Ship: 8 Days or more -

Flexible Couplings - Servo Flex.

Miki Pulley

Uses lightweight, high-strength aluminum alloy for clamp hub. Extremely high torsional rigidity supporting high responsiveness.

- Volume Discount

Days to Ship: 8 Days or more Show Stock Products

-

Flexible Couplings - High-torque disc, screw clamp type.

MISUMI

Flexible couplings, disc type, high torque and screw clamp fixing. This type of coupling can be selected with one or two intermediate discs, and can also be selected with a wedge slot at either or both ends.

- METRIC

- inCAD Components

Days to Ship: 8 Days or more -

Flexible Couplings - Disc type, servomotor, high torque, screw clamp type.

MISUMI

•Application : Servo Motor

•Body Material : Aluminum

•Allowable Misalignment : Angular, Axial, Eccentricity

•Feature : High Torque, High Torsional Rigidity, Low Moment of Inertia, No Backlash

For complete product overview and details on Couplings - Ultra High Torque Disc, Clamping, for Servo Motor see the sections below:- METRIC

- inCAD Components

Days to Ship: 8 Days or more -

Flexible Couplings - Star Flex, ALS-R series.

Miki Pulley

Flexible spider type couplings, model Star flex series ALS-R. It has a polyurethane elastomer used in the coupling separator. It has excellent anti vibration and shock absorption.

- Volume Discount

- CAD :

- 2D

Days to Ship: 22 Days or more -

Flexible Couplings - Bellows type, MFB/MFBS series.

NBK

Flexible bellows type couplings, MFB/MFBS series. The MFB series is aluminum and the MFBS series is stainless steel. Zero Backlash.

- Volume Discount

Days to Ship: 8 Days or more -

Flexible Couplings - Slotted type, with clamp type fastening.

MISUMI

Flexible grooved type couplings, with clamp type fastening. It has a spring completely integrated to the coupling body thanks to the grooves. Body material can be selected between aluminum and stainless steel.

- METRIC

- inCAD Components

Days to Ship: 8 Days or more -

Flexible Couplings - Standard torque disc, clamp type.

MISUMI

Flexible disc type couplings, standard torque and clamp fastening. This type of coupling can be selected with one or two intermediate discs, and can also be selected with a wedge slot at either or both ends.

- METRIC

- inCAD Components

Days to Ship: 8 Days or more -

Flexible Couplings - Slotted type, stainless steel.

NBK

Stainless steel grooved type flexible couplings. They feature zero backlash. The design is compact. Ideal for equipment transfer applications, XY platforms, etc.

- Volume Discount

Days to Ship: 8 Days or more -

Flexible Couplings - High-torque disc, clamp type.

MISUMI

Flexible couplings, disc type, high torque and fastening with clamp. This type of coupling can be selected with one or two intermediate discs, and can also be selected with a wedge slot at either or both ends.

- METRIC

- inCAD Components

Days to Ship: 8 Days or more -

Flexible Couplings - Disc type, for servomotor, high torque, two-bolt clamping type.

MISUMI

Flexible couplings, disc type, for servomotor, high torque and two-screw clamping. This type of coupling can be selected with one or two intermediate discs, and can also be selected with a wedge slot at either or both ends. Carbon steel or stainless steel material can be selected. Ideal for actuators.

- METRIC

- inCAD Components

Days to Ship: 8 Days or more -

Flexible Couplings - Disc, high torsional stiffness, XBS-C/XBSS-C series.

NBK

Flexible disc couplings, high torsional rigidity. Zero backlash. Selectable stainless steel or duraluminium material.

- Volume Discount

Days to Ship: 11 Days or more -

Flexible Couplings - Oldham Type, MOR series.

NBK

Oldham type flexible couplings, MOR series. Large permissible misalignment. The force generated by the eccentric reaction is small, thus reducing the load on the shaft.

- Volume Discount

Days to Ship: 8 Days or more Show Stock Products

-

Flexible Couplings - With disc, clamping type, XHW/XHW-L series.

NBK

Flexible couplings with disc, clamp-on type XHW/XHW-L series. Ideal for servo motors with a maximum instantaneous torque of 350%. For high torque and high torsional stiffness.

- Volume Discount

Days to Ship: 8 Days or more -

Flexible Couplings - SPRFLEX, AL series.

Miki Pulley

Flexible spider couplings, SPRFLEX AL series. This coupling has a separator made of nitrile rubber material. The coupling body material is aluminum. It is used in motors, pumps, fans and general purpose textile machines.

- Volume Discount

- CAD :

- 2D

Days to Ship: 8 Days or more -

- On Sale Till 15/12/2024

Flexible Couplings - Slotted type, MST/MSTS series.

NBK

Flexible grooved type couplings, MST/MSTS series. Ideal for stepper and general purpose motors, not ideal for servo motors. Zero backlash. High torque. High torsional stiffness. Allow moderate misalignment.

- Volume Discount

Special Price Days to Ship: Same day or more Show Stock Products

-

Flexible Couplings - Oldham type, stainless steel.

MISUMI

Oldham type flexible couplings, stainless steel, with carbon reinforced resin spacer. A choice of keyway at one or both ends is available.

- METRIC

- inCAD Components

Days to Ship: 8 Days or more -

Flexible Couplings - Disc, clamp-on type, MDS-C series.

NBK

Flexible disc couplings, clamping type, MDS-C series. Features high torsional rigidity, high torque and zero backlash. Compact design and short overall length. Stainless steel disc allows for eccentricity and deflection.

- Volume Discount

Days to Ship: 8 Days or more Show Stock Products

-

Flexible Couplings - Double disc type.

NBK

Double disc flexible couplings. With high torsional stiffness. Ideal for XY actuators.

- Volume Discount

Days to Ship: 8 Days or more Show Stock Products

-

Flexible Couplings - Slotted type, for servomotor, selectable fastening type.

MISUMI

Slotted type flexible couplings, for servomotor with choice of clamp or clamp fixing type. High torsional stiffness and low moment of inertia. The body material is A7075 Duraluminum. The spring is fully integrated into the coupling body thanks to the grooves.

- METRIC

- inCAD Components

Days to Ship: 8 Days or more -

- On Sale Till 15/12/2024

Flexible Couplings - Disc type, clamp-on type, XBW/XBWS series.

NBK

Flexible disc couplings with clamping type, series XBW/XBWS. It features high torque, torsional stiffness and high response. Optimal for XY surface actuators/assemblies and precision tables.

- Volume Discount

Special Price Days to Ship: 8 Days or more Show Stock Products

-

Flexible Couplings - Oldham type, clamp-on type, serrated spacer.

NBK

Oldham type flexible couplings, clamp-on type. The torque is transmitted through the toothed spacer. It has excellent flexibility.

- Volume Discount

Days to Ship: 8 Days or more -

Flexible Couplings - With rubber spacer with high damping capacity, XGT2-C/XGL2-C/XGS2-C series.

NBK

High damping capacity rubber-type standard coupling.

[Features]

· High-damping flexible coupling surpassing XGT, XGL and XGS.

· Aluminum hubs on both ends are molded with vibration-proof rubber in a completely integrated structure.

· Optimum design of damping and rigidity achieves higher servo motor gain, shortening settling time.

· Effective in suppressing speed irregularities during stepping motor drive.

· Suppresses residual vibration upon positioning and contributes to improved productivity and quality.

· Superior heat resistance, oil resistance and chemical resistance.

[Applications]

· Semiconductor manufacturing machinery, mounting machinery, machine tools, packaging machinery, etc.- Volume Discount

Days to Ship: 8 Days or more -

Flexible Couplings - With clamp type fastening and aluminum body.

MISUMI

Flexible spider type couplings with clamp type fastening. Models are available to select whether a keyway is required at one end or both.

- New Pricing

- METRIC

- inCAD Components

Days to Ship: 8 Days or more -

Flexible Couplings - Oldham type, super compact model.

MISUMI

Full Length Shortened Product with Larger Torque than Conventional Products

- METRIC

- inCAD Components

Days to Ship: 8 Days or more -

Flexible Couplings - ALS-Y series.

Miki Pulley

Flexible spider coupling, ALS-Y series. The material is aluminum. It has a polyurethane resin separator. It has a high transmission torque. It can be selected with pilot holes, with clamping or clamping type.

- Volume Discount

- CAD :

- 2D

Days to Ship: 22 Days or more -

Flexible Couplings - Slotted type, MSX series.

NBK

Flexible grooved type couplings, MSX series. High torsional rigidity and zero backlash. Ideal for servomotors.

- Volume Discount

Days to Ship: 8 Days or more -

Flexible Couplings - Disc type, for servomotor, high torque, clamping type SCPS/SCPW series.

MISUMI

Most Suitable for Servo-Motor Driven Diveces

- METRIC

- inCAD Components

Days to Ship: 8 Days or more -

Flexible Couplings - Oldham type, with multiple spacer models.

MISUMI

•Application : Standard

•Body Material : Aluminum

•Allowable Misalignment : Angular, Eccentricity

•Feature : Low Moment of Inertia

For complete product overview and details on Couplings - Oldham, Blue Set Screw / Clamping / Green Short Clamping see the sections below:- METRIC

- inCAD Components

Days to Ship: 8 Days or more -

Flexible Couplings - With polyurethane sleeve.

MISUMI

Flexible spider couplings with polyurethane sleeve. Operating temperature from -20°C to 60°C. Rotational speed from 39,000 to 19,000 depending on outside diameter.

- METRIC

- inCAD Components

Days to Ship: 8 Days or more -

Flexible Couplings - Slotted type, for low torque.

MISUMI

•Type: With Slit

•Operating Temperature Range (?): -20::80

•Allowable Torque Range (Nm): 0.05~1.00

•Allowable Lateral Misalignment Range (mm): 0.02~0.2

•Category: Coupling Main Body- METRIC

- inCAD Components

Days to Ship: 8 Days or more -

Flexible Couplings - Oldham type, short clamping.

MISUMI

•Application : Standard

•Body Material : Aluminum

•Allowable Misalignment : Angular, Eccentricity

•Feature : Low Moment of Inertia

For complete product overview and details on Couplings - Oldham, Blue Set Screw / Clamping / Green Short Clamping see the sections below:- METRIC

- inCAD Components

Days to Ship: 8 Days or more -

Flexible Couplings - Precision, leaf spring type, LAD-C series.

Sakai Manufacturing

Flexible precision couplings with leaf spring. High precision and high flexibility rotational transmission is possible due to its double clamping and backlash-free structure.

- Volume Discount

Days to Ship: 11 Days or more -

Flexible Couplings - Oldham Type, MJ series.

Mighty

Oldham type flexible couplings, MJ series. Absorption of a maximum eccentricity of 7 mm. Torque 0.06Nm~37.5Nm. Excellent electrical resistance, non-magnetic, non-lubricated. Clamping method by oppressor.

- Volume Discount

Days to Ship: 8 Days or more -

Flexible Couplings - Slotted Type, (Inch and Metric).

MISUMI

Flexible grooved type couplings, with a choice of metric and inch sizes. The material can be selected between stainless steel or aluminum.

- Volume Discount

- METRIC

- INCH

Days to Ship: 8 Days or more -

Flexible Couplings - Oldham Type, selectable clamping type, MOS series.

NBK

Oldham type flexible couplings, with clamping or clamping type of fastening. This model allows a high level of misalignment.

- Volume Discount

Days to Ship: 8 Days or more -

Flexible Couplings - Crosshead type, clamp-on type.

NBK

Flexible crosshead type couplings, clamped by clamping. High torsional rigidity. Low eccentric force reaction and minimum backlash.

- Volume Discount

Days to Ship: 11 Days or more -

Flexible Couplings - Bellows type, NB series.

Nihon Miniature Coupling

Flexible couplings, bellows type, NB series, clamp fixing system. The material is Bronze and Brass. Ideal for use to connect encoders, medical equipment and servo motors.

- Volume Discount

- CAD :

- 2D

Days to Ship: 9 Days or more -

Flexible Couplings - Bellows type, NA series (collet type).

Nihon Miniature Coupling

Flexible couplings, bellows type, NB series, clamp fixing system. The material is Bronze and Brass. Ideal for use in connecting encoders, medical equipment and servo motors. The performance is the same as the NA series without collet, but this design allows easier assembly and disassembly without damaging the shaft.

- Volume Discount

- CAD :

- 2D

Days to Ship: 10 Days or more

| Brand |

|---|

| Product Series |

| CAD |

| Days to Ship |

| Specifications |

| Type |

| Allowable Misalignment |

| Application |

| Allowable Torque Range(N•m) |

| For Shaft Size D1(mm) |

| For Shaft Size D2(mm) |

| Outer Dia. A(Ø) |

| Overall Length W(mm) |

| Max. Rotational Speed Range(r/min) |

| Feature |

| Body Material |

| Category |

| Allowable Torque(N•m) |

| Max. Rotational Speed(r/min) |

| Allowable Angular Misalignment(deg) |

| Allowable Lateral Misalignment Range(mm) |

| Allowable Lateral Misalignment(mm) |

| Buffer Part Material |

| Disc Part Material |

| Bellows Part Material |

| For Shaft Size D1(inch) |

| For Shaft Size D2(inch) |

|

|

|

| ||||||||||||||||||||||||||||||||||||||||||

| Brand | R+W | NBK | NBK | MISUMI | MISUMI | MISUMI | MISUMI | Miki Pulley | MISUMI | MISUMI | Miki Pulley | NBK | MISUMI | MISUMI | NBK | MISUMI | MISUMI | NBK | NBK | NBK | Miki Pulley | NBK | MISUMI | NBK | NBK | MISUMI | NBK | NBK | NBK | MISUMI | MISUMI | Miki Pulley | NBK | MISUMI | MISUMI | MISUMI | MISUMI | MISUMI | Sakai Manufacturing | Mighty | MISUMI | NBK | NBK | Nihon Miniature Coupling | Nihon Miniature Coupling |

| Product Series | Flexible Couplings - Bellows type, miniature, zero backlash, MK2 series. | Flexible Couplings - For high torque and vibration absorption. | Flexible Couplings - Slotted type, standard length or compact. | Flexible Couplings - Standard torque disc, screw clamp type. | Flexible Couplings - Bellows type, selectable fastening type. | Flexible Couplings - Disc type, servomotor, high torque, screw clamp type. | Flexible Couplings - Slotted type, with clamp type fastening. | Flexible Couplings - Disc type, for servomotor, high torque, two-bolt clamping type. | Flexible Couplings - Disc, high torsional stiffness, XBS-C/XBSS-C series. | Flexible Couplings - With disc, clamping type, XHW/XHW-L series. | Flexible Couplings - Slotted type, for servomotor, selectable fastening type. | Flexible Couplings - Disc type, clamp-on type, XBW/XBWS series. | Flexible Couplings - Oldham type, clamp-on type, serrated spacer. | Flexible Couplings - With rubber spacer with high damping capacity, XGT2-C/XGL2-C/XGS2-C series. | Flexible Couplings - With clamp type fastening and aluminum body. | Flexible Couplings - Disc type, for servomotor, high torque, clamping type SCPS/SCPW series. | Flexible Couplings - Oldham type, with multiple spacer models. | Flexible Couplings - Precision, leaf spring type, LAD-C series. | Flexible Couplings - Oldham Type, selectable clamping type, MOS series. | ||||||||||||||||||||||||||

| CAD |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||||

| Days to Ship | 5 Days or more |

8 Days or more

Show Stock Products | 8 Days or more | 8 Days or more | 8 Days or more | 8 Days or more | 8 Days or more |

8 Days or more

Show Stock Products | 8 Days or more | 8 Days or more | 22 Days or more | 8 Days or more | 8 Days or more | 8 Days or more | 8 Days or more | 8 Days or more | 8 Days or more | 11 Days or more |

8 Days or more

Show Stock Products | 8 Days or more | 8 Days or more |

Same day or more

Show Stock Products | 8 Days or more |

8 Days or more

Show Stock Products |

8 Days or more

Show Stock Products | 8 Days or more |

8 Days or more

Show Stock Products | 8 Days or more | 8 Days or more | 8 Days or more | 8 Days or more | 22 Days or more | 8 Days or more | 8 Days or more | 8 Days or more | 8 Days or more | 8 Days or more | 8 Days or more | 11 Days or more | 8 Days or more | 8 Days or more | 8 Days or more | 11 Days or more | 9 Days or more | 10 Days or more |

| Specifications |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |||||||||||||||||||||||||

| Type | Bellows Type | Oldham Type | Jaw Type | Jaw Type | With Slit | Disc Type | Bellows Type | Disc Type | Disc Type | Disc Type | Jaw Type | Bellows Type | With Slit | Disc Type | With Slit | Disc Type | Disc Type | Disc Type | Oldham Type | Disc Type | Jaw Type | With Slit | Oldham Type | Disc Type | Disc Type | With Slit | Disc Type | Oldham Type | Oldham Type | Jaw Type | Oldham Type | Jaw Type | With Slit | Disc Type | Oldham Type | Oldham Type | With Slit | Oldham Type | Disc Type | Oldham Type | With Slit | Oldham Type | With Slit | Bellows Type | Bellows Type |

| Allowable Misalignment | - | Angular / Eccentricity / Axial | Angular / Eccentricity / Axial | Angular / Eccentricity / Axial | Angular / Eccentricity / Axial | Angular / Eccentricity / Axial | Angular / Eccentricity / Axial | Angular / Eccentricity / Axial | Angular / Eccentricity / Axial | Angular / Eccentricity / Axial | Angular / Eccentricity / Axial | Angular / Eccentricity / Axial | Angular / Eccentricity / Axial | Angular / Eccentricity / Axial | Angular / Axial | Angular / Eccentricity / Axial | Angular / Eccentricity / Axial | Angular / Axial | Angular / Eccentricity | - | Angular / Eccentricity / Axial | Angular / Eccentricity / Axial | Angular / Eccentricity / Axial | Angular / Eccentricity / Axial | Angular / Eccentricity / Axial | Angular / Eccentricity / Axial | Angular / Eccentricity / Axial | Angular / Eccentricity | - | Angular / Eccentricity / Axial | Angular / Eccentricity | Angular / Eccentricity / Axial | Angular / Eccentricity / Axial | Angular / Eccentricity / Axial | Angular / Eccentricity | Angular / Eccentricity | Angular / Eccentricity / Axial | Angular / Eccentricity | Angular / Eccentricity / Axial | Angular / Eccentricity | Angular / Eccentricity / Axial | Angular / Eccentricity | Angular / Eccentricity | Angular / Eccentricity / Axial | Angular / Eccentricity / Axial |

| Application | - | Standard / Servo Motor / Stepping Motor | Standard / Servo Motor / Stepping Motor | Standard | Standard | Standard | Encoder | Servo Motor / Stepping Motor / Encoder | Standard | Servo Motor | Standard / Servo Motor / Stepping Motor / Encoder | Stepping Motor | Standard | Standard | Standard / Stepping Motor | Standard | Servo Motor | Standard / Servo Motor / Stepping Motor | Standard / Stepping Motor | Standard / Servo Motor / Stepping Motor | Standard / Stepping Motor | Standard / Stepping Motor | Standard | Standard / Servo Motor / Stepping Motor | Standard / Servo Motor / Stepping Motor | Servo Motor | Standard / Servo Motor / Stepping Motor | Standard | Standard / Servo Motor / Stepping Motor | Standard | Standard | Standard / Servo Motor / Stepping Motor / Encoder | Standard / Servo Motor / Stepping Motor | Servo Motor | Standard | Standard | Encoder | Standard | Standard / Servo Motor / Stepping Motor / Encoder | Standard / Servo Motor / Stepping Motor / Encoder | Standard | Standard / Stepping Motor | Servo Motor / Stepping Motor | Standard | Standard |

| Allowable Torque Range(N•m) | 0.05~1.00 | 0.05~1.00 | 0.05~1.00 | 0.05~1.00 | 0.05~1.00 | 0.05~1.00 | 0.05~1.00 | 0.05~1.00 | 0.05~1.00 | 0.05~1.00 | 0.05~1.00 | 0.05~1.00 | 0.05~1.00 | 0.05~1.00 | 0.05~1.00 | 0.05~1.00 | 0.05~1.00 | 0.05~1.00 | 0.05~1.00 | 0.05~1.00 | 0.05~1.00 | 0.05~1.00 | 0.05~1.00 | 0.05~1.00 | 0.05~1.00 | 0.05~1.00 | 0.05~1.00 | 0.05~1.00 | 0.05~1.00 | 0.05~1.00 | 0.05~1.00 | 0.05~1.00 | 0.05~1.00 | 0.05~1.00 | 0.05~1.00 | 0.05~1.00 | 0.05~1.00 | 0.05~1.00 | 0.05~1.00 | 0.05~1.00 | 0.05~1.00 | 0.05~1.00 | 0.05~1.00 | 0.05~1.00 | 0.05~1.00 |

| For Shaft Size D1(mm) | 0-Pilot Bore ~ 7 | 3 ~ 8 | 3 ~ 6 | 3 ~ 5 | 4 ~ 8 | 3 ~ 8 | 3 ~ 10 | 3 ~ 8 | 3 ~ 8 | 4 ~ 6 | 3 ~ 6 | 3 ~ 10 | 2 ~ 10 | 2 ~ 10 | 2 ~ 10 | 2 ~ 10 | 4 ~ 12 | 3 ~ 8 | 1 ~ 3 | 3 ~ 6 | 6 ~ 7 | 2 ~ 10 | 1 ~ 5 | 4 ~ 12 | 4 ~ 12 | 5 ~ 10 | 3 ~ 8 | 3 ~ 10 | 3 ~ 6 | 3 ~ 6 | 3 ~ 8 | 3 ~ 6 | 5 ~ 10 | 3 ~ 6 | 3 ~ 6.35 | 3 ~ 10 | 1.5 ~ 12 | 3 ~ 8 | 3 ~ 5 | 2 ~ 6 | - | 1 ~ 8 | 3 ~ 8 | 2 ~ 10 | 5 ~ 8 |

| For Shaft Size D2(mm) | 0-Pilot Bore ~ 7 | 3 ~ 8 | 3 ~ 6 | 3 ~ 5 | 4 ~ 8 | 3 ~ 8 | 3 ~ 10 | 3 ~ 8 | 3 ~ 8 | 4 ~ 6 | 3 ~ 6 | 3 ~ 10 | 2 ~ 10 | 2 ~ 10 | 2 ~ 10 | 2 ~ 10 | 4 ~ 12 | 3 ~ 8 | 1 ~ 3 | 3 ~ 6 | 6 ~ 8 | 2 ~ 10 | 1 ~ 5 | 4 ~ 12 | 4 ~ 12 | 5 ~ 10 | 3 ~ 8 | 3 ~ 10 | 3 ~ 6 | 3 ~ 6 | 3 ~ 8 | 3 ~ 6 | 5 ~ 10 | 3 ~ 6 | 3 ~ 6.35 | 3 ~ 10 | 1.5 ~ 12 | 3 ~ 8 | 3 ~ 5 | 2 ~ 6 | - | 1 ~ 8 | 3 ~ 8 | 2 ~ 10 | 5 ~ 8 |

| Outer Dia. A(Ø) | 15 | 15 ~ 19 | 14 | 14 | 12 ~ 20 | 13 ~ 20 | 12 ~ 20 | 12 ~ 19 | 13 ~ 20 | 16 | 14 | 12 ~ 20 | 8 ~ 20 | 10 ~ 20 | 8 ~ 20 | 10 ~ 20 | 19 ~ 25 | 15 ~ 19 | 6 ~ 8 | 15 | 16.1 | 8 ~ 20 | 6 ~ 12 | 19 ~ 25 | 19 ~ 25 | 16 ~ 19 | 15 ~ 19 | 16 ~ 20 | 15 | 14 | 12 ~ 20 | 14 | 16 ~ 19 | 16.6 | 16 | 16 ~ 20 | 8 ~ 28 | 12 ~ 20 | 12 ~ 15 | 6.4 ~ 12.7 | 12 ~ 20 | 8 ~ 20 | 15 ~ 20 | 14 ~ 19 | 18 ~ 20 |

| Overall Length W(mm) | 25 ~ 33 | 18 ~ 20 | 22 | 22 | 14 ~ 26 | 13.5 ~ 26 | 23.5 ~ 33 | 15.7 ~ 25.9 | 13.5 ~ 26 | 16.5 ~ 23.2 | 22 | 23.5 ~ 33 | 10 ~ 26 | 10.5 ~ 26 | 10 ~ 20 | 10.5 ~ 26 | 20 ~ 31 | 16 ~ 19 | 8.4 ~ 9.6 | 21.6 | 20.5 | 14 ~ 26 | 8.4 ~ 14.2 | 20 ~ 24 | 27 ~ 31 | 17.4 ~ 20 | 22 ~ 25.5 | 27 ~ 34 | 18 | 22 | 13.5 ~ 19 | 22 | 17.4 ~ 20 | 16.6 ~ 23 | 18 ~ 29 | 27 ~ 34 | 9 ~ 34.4 | 14.9 ~ 22.1 | 15.8 ~ 20 | 12.7 ~ 15.9 | - | 12.7 ~ 22.1 | 18 ~ 20 | 22 ~ 28 | 25 |

| Max. Rotational Speed Range(r/min) | 4001~10000 | 10001~78000 | 10001~78000 | 10001~78000 | 10001~78000 | 4001~10000 ~ 10001~78000 | 10001~78000 | 4001~10000 | 4001~10000 ~ 10001~78000 | 4001~10000 | 4001~10000 | 10001~78000 | 10001~78000 | 10001~78000 | 10001~78000 | 10001~78000 | 10001~78000 | 10001~78000 | 10001~78000 ~ 78001~ | 10001~78000 | 10001~78000 | 10001~78000 | 10001~78000 | 10001~78000 | 10001~78000 | 10001~78000 | 10001~78000 | 10001~78000 | 10001~78000 | 10001~78000 | 4001~10000 ~ 10001~78000 | 4001~10000 | 10001~78000 | 4001~10000 | 10001~78000 | 10001~78000 | 2001~4000 ~ 10001~78000 | 10001~78000 | 4001~10000 | - | 4001~10000 ~ 10001~78000 | 10001~78000 | 10001~78000 | 4001~10000 | 4001~10000 |

| Feature | Low Moment of Inertia ~ Unfinished Shaft Bore | High Torque ~ Vibration Insulation | High Torque ~ Vibration Insulation | High Torque ~ Low Moment of Inertia | Low Moment of Inertia ~ No Backlash | Low Moment of Inertia ~ No Backlash | Low Moment of Inertia ~ No Backlash | High Accuracy ~ Small | High Torque ~ No Backlash | High Torque ~ No Backlash | High Accuracy ~ Vibration Insulation | No Backlash | Low Moment of Inertia ~ No Backlash | Low Moment of Inertia ~ No Backlash | High Torque ~ No Backlash | High Torque ~ No Backlash | Low Moment of Inertia ~ No Backlash | High Torque ~ No Backlash | High Torque | High Torque ~ No Backlash | Unfinished Shaft Bore ~ Vibration Insulation | High Torque ~ No Backlash | High Torque ~ Low Moment of Inertia | No Backlash | No Backlash | Low Moment of Inertia ~ No Backlash | High Torque ~ No Backlash | Vibration Insulation | High Torque ~ Vibration Insulation | High Torque ~ Low Moment of Inertia | Low Moment of Inertia ~ Small | Low Moment of Inertia ~ Vibration Insulation | High Torque ~ No Backlash | High Torque ~ No Backlash | Low Moment of Inertia | Low Moment of Inertia | Low Moment of Inertia ~ No Backlash | Low Moment of Inertia | High Torsional Rigidity ~ Low Moment of Inertia | High Accuracy ~ Vibration Insulation | - | - | High Torque ~ Vibration Insulation | High Torsional Rigidity ~ Small | High Torsional Rigidity ~ Small |

| Body Material | Aluminum | Aluminum | Aluminum | Aluminum | Aluminum ~ Stainless Steel | Aluminum | Aluminum ~ Stainless Steel | Aluminum | Aluminum | Aluminum | Aluminum | Aluminum ~ Stainless Steel | Aluminum ~ Stainless Steel | Aluminum | Aluminum ~ Stainless Steel | Aluminum | Aluminum | Aluminum ~ Stainless Steel | Aluminum | Aluminum | Aluminum | Aluminum ~ Stainless Steel | Stainless Steel | Aluminum | Aluminum | Aluminum | Aluminum ~ Stainless Steel | Alloy | Aluminum | Aluminum | Aluminum | Aluminum | Aluminum | Aluminum | Aluminum | Alloy | Resin | Aluminum | Aluminum | Alloy | Aluminum ~ Stainless Steel | Aluminum | Aluminum | Alloy | Stainless Steel |

| Category | - | Coupling Main Body | Coupling Main Body | Coupling Main Body | Coupling Main Body | Coupling Main Body | Coupling Main Body | Coupling Main Body | Coupling Main Body | Coupling Main Body | Coupling Main Body | Coupling Main Body | Coupling Main Body | Coupling Main Body | Coupling Main Body | Coupling Main Body | Coupling Main Body | Coupling Main Body | Coupling Main Body | Coupling Main Body | Coupling Main Body | Coupling Main Body | Coupling Main Body | Coupling Main Body | Coupling Main Body | Coupling Main Body | Coupling Main Body | Coupling Main Body | Coupling Main Body | Coupling Main Body | Coupling Main Body | Coupling Main Body | Coupling Main Body | Coupling Main Body | Coupling Main Body | Coupling Main Body | Coupling Main Body | Coupling Main Body | Coupling Main Body | - | Coupling Main Body | Coupling Main Body | Coupling Main Body | Coupling Main Body | Coupling Main Body |

| Allowable Torque(N•m) | 0.5 ~ 1 | 0.5 ~ 0.8 | 0.7 | 0.7 | 0.3 ~ 1 | 0.25 ~ 0.6 | 0.3 ~ 1 | 0.25 ~ 1 | 0.35 ~ 0.9 | 0.9 | 0.31 ~ 0.65 | 0.3 ~ 1 | 0.1 ~ 1 | 0.15 ~ 0.6 | 0.1 ~ 1 | 0.25 ~ 1 | 0.7 ~ 1 | 0.42 ~ 1 | 0.4 ~ 1 | 0.6 | 0.5 | 0.1 ~ 1 | 0.3 ~ 1 | 0.7 ~ 1 | 0.7 ~ 1 | 0.5 ~ 1 | 0.6 ~ 1 | 0.5 ~ 1 | 1 | 0.7 | 0.3 ~ 1 | 0.31 ~ 0.65 | 0.5 ~ 1 | 1 | 0.7 | 0.5 ~ 1 | 0.05 ~ 0.8 | 0.2 ~ 0.7 | 0.25 ~ 0.6 | 0.06 ~ 0.5 | 0.39 ~ 0.99 | 0.08 ~ 0.7 | 0.3 ~ 0.6 | 0.147 ~ 0.343 | 0.7845 |

| Max. Rotational Speed(r/min) | 10,000 | 33000 ~ 42000 | 45000 | 45000 | 31000 ~ 52000 | 7600 ~ 12000 | 31000 ~ 52000 | 10000 | 7600 ~ 12000 | 6000 | 10000 | 31000 ~ 52000 | 31000 ~ 78000 | 18000 ~ 26000 | 31000 ~ 78000 | 22000 ~ 32000 | 25000 ~ 33000 | 33000 ~ 42000 | 78000 ~ 100000 | 42000 | 18000 | 31000 ~ 78000 | 12000 | 25000 ~ 33000 | 25000 ~ 33000 | 33000 ~ 39000 | 33000 ~ 42000 | 31000 ~ 39000 | 42000 | 45000 | 6000 ~ 12000 | 10000 | 33000 ~ 39000 | 10000 | 39000 | 31000 ~ 39000 | 4000 ~ 12000 | 31000 ~ 52000 | 10000 | - | 7600 ~ 12000 | 31000 ~ 78000 | 31000 ~ 42000 | 5000 | 10000 |

| Allowable Angular Misalignment(deg) | 1 ~ 2 | 1.5 | 1 | 1 | 1 ~ 2 | 2 ~ 3.5 | 1.5 ~ 2 | 0.5 ~ 2 | 1 ~ 2.5 | 1 ~ 2 | 1 | 1.5 ~ 2 | 1 ~ 2 | 2 ~ 3.5 | 1 | 1 ~ 2.5 | 0.7 ~ 1.5 | 0.5 ~ 1 | 3 | 1.4 | 0.5 | 2 | 3 | 0.7 | 1.5 | 0.5 | 1 ~ 2 | 2 | 1.5 | 1 | 1.5 | 1 | 0.5 | 1 | 3 | 2 | 2 ~ 2.5 | 2 | 0.5 | 1 | 2 | 2 | 1 | 1.5 | 2 |

| Allowable Lateral Misalignment Range(mm) | 0.02~0.2 ~ 0.21~0.40 | 0.02~0.2 | 0.02~0.2 | 0.02~0.2 | 0.02~0.2 | 0.02~0.2 ~ 0.21~0.40 | 0.02~0.2 | 0.02~0.2 | 0.02~0.2 | 0.02~0.2 | 0.02~0.2 | 0.02~0.2 | 0.02~0.2 | 0.02~0.2 ~ 0.21~0.40 | - | 0.02~0.2 | 0.02~0.2 | 0.02~0.2 | 0.41~1.0 | 0.02~0.2 | 0.02~0.2 | 0.02~0.2 | 0.21~0.40 ~ 0.41~1.0 | 0.02~0.2 | 0.02~0.2 | 0.02~0.2 | 0.02~0.2 | 0.02~0.2 | 0.02~0.2 | 0.02~0.2 | 0.21~0.40 ~ 0.41~1.0 | 0.02~0.2 | 0.02~0.2 | 0.02~0.2 | 0.41~1.0 | 0.02~0.2 | 0.02~0.2 | 0.41~1.0 ~ 1.1~3.0 | 0.02~0.2 | 0.41~1.0 ~ 1.1~3.0 | 0.02~0.2 | 0.41~1.0 ~ 1.1~3.0 | 0.02~0.2 | 0.02~0.2 | 0.02~0.2 |

| Allowable Lateral Misalignment(mm) | 0.15 ~ 0.25 | 0.15 | - | 0.15 | 0.1 | 0.1 ~ 0.3 | 0.1 ~ 0.15 | 0.02 ~ 0.11 | 0.05 ~ 0.2 | 0.15 | 0.1 | 0.1 ~ 0.15 | 0.1 | 0.1 ~ 0.3 | - | 0.05 ~ 0.2 | 0.12 | 0.02 | 0.5 ~ 0.7 | 0.1 | 0.1 | 0.1 | 0.3 ~ 0.5 | 0.02 | 0.12 | 0.05 | 0.05 ~ 0.15 | 0.2 | 0.15 | 0.15 | 0.3 ~ 1 | 0.1 | 0.05 | 0.1 | 1 | 0.2 | 0.05 ~ 0.2 | 0.6 ~ 1.3 | 0.03 | 0.8 ~ 1.6 | 0.004(inch) | 0.5 ~ 1.3 | 0.2 | 0.1 ~ 0.2 | 0.1 |

| Buffer Part Material | - | Others | Polyurethane | Polyurethane | - | - | - | - | - | - | Polyurethane | - | - | - | - | - | - | - | Polyacetal | - | Others | - | Carbon Reinforced Resin | - | - | - | - | Polyurethane | Fluororubber | Polyurethane | Polyacetal | Polyurethane | - | - | Polyacetal | - | - | Polyacetal | - | Polyacetal | - | Polyacetal | - | - | - |

| Disc Part Material | - | - | - | - | - | Polyimide | - | Stainless Steel | Carbon Fiber | Stainless Steel | - | - | - | Polyimide | - | Carbon Fiber | Stainless Steel | Stainless Steel | - | Stainless Steel | - | - | - | Stainless Steel | Stainless Steel | - | Stainless Steel | - | - | - | - | - | - | Stainless Steel | - | - | - | - | Stainless Steel | - | - | - | - | - | - |

| Bellows Part Material | Stainless Steel | - | - | - | - | - | Stainless Steel / Phosphor Bronze | - | - | - | - | Stainless Steel / Phosphor Bronze | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | Phosphor Bronze | Stainless Steel |

| For Shaft Size D1(inch) | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - |

| For Shaft Size D2(inch) | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - |

Loading...

Configure

Stock

-

- Show Stock Products

Specification/Dimensions

-

Allowable Misalignment

-

None

None -

Angular

Angular -

Eccentricity

Eccentricity -

Axial

Axial

-

-

Application

- Standard

- Servo Motor

- Stepping Motor

- Encoder

-

Allowable Torque Range(N•m)

-

Metric / Inch

- metric

- inch

-

For Shaft Size D1(mm)

-

For Shaft Size D2(mm)

-

Outer Dia. A(Ø)

- 6

- 6.4

- 8

- 9

- 9.5

- 10

- 12

- 12.7

- 13

- 13.5

- 14

- 14.5

- 15

- 16

- 16.1

- 16.6

- 16.8

- 17

- 18

- 19

- 19.1

- 20

- 21

- 22

- 24

- 25

- 25.4

- 26

- 27

- 27.3

- 28

- 29

- 30

- 31.7

- 32

- 33.3

- 34

- 34.4

- 35

- 36

- 38

- 39

- 40

- 41.3

- 42

- 44

- 44.5

- 45

- 46

- 48

- 49

- 50

- 53.6

- 54

- 54.5

- 55

- 56

- 57

- 58

- 60

- 63

- 64

- 65

- 66

- 66.5

- 67

- 68

- 70

- 75

- 79

- 80

- 81

- 82

- 85

- 87

- 88

- 90

- 94

- 95

- 100

- 102

- 104

- 105

- 110

- 118

- 123

- 125

- 126

- 144

- 155

-

Overall Length W(mm)

- 5.1

- 7.3

- 8.4

- 9

- 9.4

- 9.6

- 10

- 10.2

- 10.5

- 11.2

- 11.8

- 12.4

- 12.7

- 13.5

- 14

- 14.2

- 14.6

- 14.9

- 15

- 15.5

- 15.7

- 15.8

- 15.9

- 16

- 16.2

- 16.5

- 16.6

- 16.7

- 17.4

- 17.8

- 18

- 18.1

- 18.4

- 18.5

- 18.8

- 19

- 19.35

- 19.4

- 19.8

- 20

- 20.2

- 20.4

- 20.5

- 21

- 21.2

- 21.4

- 21.5

- 21.6

- 22

- 22.1

- 22.5

- 23

- 23.1

- 23.15

- 23.2

- 23.3

- 23.4

- 23.5

- 23.6

- 24

- 24.4

- 24.5

- 25

- 25.5

- 25.6

- 25.7

- 25.9

- 26

- 26.2

- 26.5

- 26.6

- 27

- 27.2

- 27.3

- 27.4

- 28

- 28.2

- 28.4

- 29

- 29.8

- 30

- 30.2

- 30.4

- 31

- 31.2

- 31.6

- 32

- 32.2

- 32.3

- 32.5

- 32.7

- 32.8

- 33

- 33.3

- 33.8

- 34

- 34.4

- 35

- 36

- 36.5

- 36.8

- 37.2

- 37.4

- 37.8

- 38

- 38.2

- 38.6

- 39

- 39.2

- 39.4

- 39.5

- 40

- 40.5

- 41

- 41.8

- 42

- 43.2

- 43.4

- 43.6

- 44

- 44.7

- 44.8

- 45

- 45.2

- 46

- 46.6

- 47

- 47.6

- 48

- 48.4

- 49.2

- 49.4

- 50

- 50.2

- 50.6

- 50.8

- 51

- 51.2

- 52

- 53

- 53.4

- 53.6

- 54

- 54.1

- 54.4

- 54.5

- 54.6

- 55

- 55.5

- 56

- 56.5

- 56.6

- 57

- 58

- 58.2

- 58.6

- 59

- 59.7

- 59.8

- 60

- 60.4

- 61

- 61.2

- 62

- 63.4

- 63.6

- 63.8

- 64.8

- 65

- 65.6

- 66

- 66.6

- 67

- 67.5

- 68

- 68.3

- 68.6

- 68.7

- 68.8

- 69

- 69.6

- 69.8

- 70

- 70.5

- 70.6

- 71

- 71.2

- 72

- 73

- 73.3

- 74

- 74.4

- 74.8

- 75

- 75.6

- 77

- 77.6

- 77.8

- 78

- 78.8

- 79

- 79.5

- 79.8

- 80

- 80.8

- 81

- 82

- 83

- 83.6

- 84

- 84.7

- 85.5

- 85.6

- 86

- 88

- 89.3

- 89.6

- 90

- 90.8

- 91

- 92

- 93

- 93.6

- 94

- 95

- 95.6

- 96

- 97

- 97.2

- 98

- 98.6

- 99

- 99.6

- 100

- 101.6

- 102

- 104.4

- 105.8

- 106

- 107

- 107.6

- 109

- 110

- 112.8

- 113

- 114

- 115.6

- 119.6

- 120

- 120.8

- 123.6

- 125

- 126

- 127

- 129.6

- 130

- 137.6

- 140

- 143

- 144

- 150

- 150.6

- 154

- 154.6

- 160

- 170.6

-

Max. Rotational Speed Range(r/min)

-

Feature

-

Body Material

-

Category

- Coupling Main Body

- Maintenace Parts

-

Allowable Torque(N•m)

-

Max. Rotational Speed(r/min)

-

Allowable Angular Misalignment(deg)

-

Allowable Lateral Misalignment Range(mm)

-

Allowable Lateral Misalignment(mm)

-

Buffer Part Material

-

Disc Part Material

-

Bellows Part Material

-

For Shaft Size D1(inch)

-

For Shaft Size D2(inch)

Narrow search by specifying Manufacturer

CAD

-

- 2D

- 3D

Days to Ship

-

- All

- Same day

- 5 Days or Less

- 6 Days or Less

- 8 Days or Less

- 9 Days or Less

- 10 Days or Less

- 11 Days or Less

- 12 Days or Less

- 13 Days or Less

- 14 Days or Less

How can we improve?

How can we improve?

While we are not able to respond directly to comments submitted in this form, the information will be reviewed for future improvement.

Customer Privacy Policy

Thank you for your cooperation.

While we are not able to respond directly to comments submitted in this form, the information will be reviewed for future improvement.

Please use the inquiry form.

Customer Privacy Policy