(!)Due to Microsoft's end of support for Internet Explorer 11 on 15/06/2022, this site does not support the recommended environment.

Mon. - Fri. 8 a.m. - 6 p.m.

All Categories

Categories

- Automation Components

- Linear Motion

- Rotary Motion

- Connecting Parts

- Rotary Power Transmission

- Motors

- Conveyors & Material Handling

- Locating, Positioning, Jigs & Fixtures

- Inspection

- Sensors, Switches

- Pneumatics, Hydraulics

- Vacuum Components

- Hydraulic Equipment

- Spray Equipment And Accessories

- Pipe, Tubes, Hoses & Fittings

- Modules, Units

- Heaters, Temperature Control

- Aluminum Extrusions, Framing, Support & Posts

- Casters, Leveling Mounts, Posts

- Doors, Cabinet Hardware

- Springs, Shock Absorbers

- Adjustment/Fastening Components, Pins, Magnets

- Antivibration, Soundproofing Materials, Safety Products

- Fasteners

- Materials

- Wiring Components

- LAN Cables / Industrial Network Cables

- Equipment Specific Cables

- Cordsets

- Computer & AV Cables

- Wire/Cable

- Connector (General Purpose)

- Crimp Terminal Components

- Cable Organization

- Cable Gland Components

- Cable Bushing/Clip/Sticker

- Screw/Spacer

- Cable accessories

- Tube

- Electrical Conduits

- Duct/Wiring

- Electrical Wiring Tools

- Dedicated tools

- Soldering supplies

- Electrical & Controls

- Cutting Tools

- Carbide End Mill

- HSS End Mill

- Concrete Drill Bits

- Milling Cutter Insert / Holder

- Core Drill Bits

- Customized Straight Blade End Mill

- Dedicated Cutter

- Crinkey Cutters

- Turning Tool

- Drill

- Cutting Tool Accessories

- Screw Hole Related Tools

- Reamer

- Electric Drill Bits

- Chamfering, Centering Tool

- Hole Saws

- Magnetic Drill Press Cutters

- Step Drills

- Wood Drills & Cutters

- Processing Tools

- packing & logistics storage supplies

- Safety Products

- research and development & cleanroom supplies

- Press Die Components

- Plastic Mold Components

- Ejector Pins

- Sleeves, Center Pins

- Core Pins

- Sprue bushings, Gates, and other components

- Date Mark Inserts, Recycle Mark Inserts, Pins with Gas Vent

- Undercut, Plates

- Leader Components, Components for Ejector Space

- Mold Opening Controllers

- Cooling or Heating Components

- Accessories, Others

- Components of Large Mold, Die Casting

- Injection Molding Components

- Purging Agent

- Injection Molding Machine Products

- Accessories of Equipment

- Auxiliary Equipment

- Air Nippers

- Air Cylinders

- Air Chuck for Runner

- Chuck Board Components

- Frames

- Suction Components

- Parallel Air Chuck

- Special Air Chuck

- Mold Maintenance

- Heating Items

- Heat Insulation Sheets

- Couplers, Plugs, One-touch Joints

- Tubes, Hoses, Peripheral Components

Applications

Brands

- Webcode Seach | Series

-

#CODE

- Discontinued Products

Suruga Seiki Manual XY-Axis Stages

| Days to Ship |

|

|---|

-

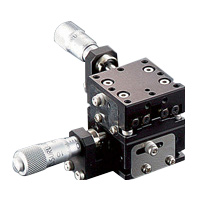

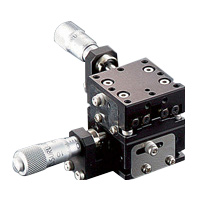

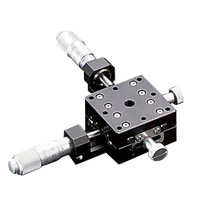

Manual XY-Axis Stages - Cross Roller Guide, High Accuracy, Lightweight, B21

Suruga Seiki

A light weight, high accuracy cross roller guide type stage (XY-axis).[Features]・ The main material is aluminum, so it is lightweight

・ High-accuracy stage with high rigidity, low friction and excellent minute feeding

・ Size, feed position, orientation specifications, feed method can be selected as options

[Applications]・ Precision adjustment of cameras, microscopes, sensors and optical components

・ Positioning of production, assembly and inspection processes related to semiconductors and measuring instruments.- Volume Discount

Days to Ship: 8 Days or more -

Manual XY-Axis Stages - Dovetail, Rack and Pinion, B05/B06

Suruga Seiki

A rack and pinion type stage (XY-axis) that is ideal for making quick and large movements.

[Features]

・ It consists of a rack rail and a pinion gear, and can be moved greatly with 1 rotation of the handle

・ Ideal for easy alignment and evacuation

・ B05 adopts the original clamp and can be clamped with a single-action

・ With a vernier scale (0.1 mm)

[Applications]

・ Adjustment of cameras, microscopes and sensors, and optical parts

・ Positioning of production, assembly and inspection processes related to semiconductors and measuring instruments- Volume Discount

Days to Ship: 11 Days or more -

Manual XY-Axis Stages - Cross Roller Guide, Through Hole, B27

Suruga Seiki

A through-hole type cross roller guide (XY-axis) with an integrated XY-axis structure.[Features]・ Lightweight because aluminum is used for the main body material. · The thickness of the body can be reduced compared to a single-axis combination. ・ The diameter of the through-hole is ø50 (diameter: 50 mm), and ø40 (diameter: 40 mm) is maintained even when the stroke is made to XY.

·

[Applications]・ Ideal for fine positioning as a sample inspection table.

・ Ideal for adjusting the dispenser head.

・ Ideal for CCD camera alignment.- Volume Discount

Days to Ship: 8 Days or more -

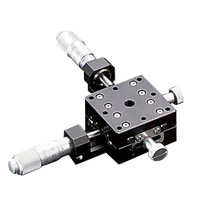

Manual XY-Axis Stages - Linear Ball Guide, Stainless Steel, Electroless Nickel Plating, BSS26

Suruga Seiki

A highly accurate, high rigidity linear ball guide type stage (XY-axis).[Features]・ Achieved high stiffness and high accuracy by adopting stainless steel as the body material and gothic arch grooves in the guide part.

・ The perpendicularity of assembly is within 10 μm.

・ There are 7 stage surface sizes available: 25 × 25 mm, 40 × 40 mm, 50 × 50 mm, 60 × 60 mm, 70 × 70 mm, 80 × 80 mm, and 100 × 100 mm square.

・ The feed position can be selected from the center or the side drive.

・ A wide variety of feeding methods are available.

[Applications]・ Precision adjustment of cameras, microscopes, sensors and optical components

・ Positioning of production, assembly and inspection processes related to semiconductors and measuring instruments- Volume Discount

Days to Ship: 10 Days or more -

Manual XY-Axis Stages - Cross Roller Guide, Low Profile, B23

Suruga Seiki

A low profile cross roller guide stage (XY-axis) with an integrated XY-axis structure.[Features]・ Lightweight as the body material is made of aluminum

・ The thickness of the main body can be reduced compared to the single axis combination.

・ Available in 40 mm, 60 mm, 80 mm, and 100 mm square stage sizes

[Applications]・ Ideal for fine positioning as a sample inspection table.

・ Ideal for adjusting the dispenser head.

・ Ideal for CCD camera alignment.- Volume Discount

Days to Ship: 8 Days or more -

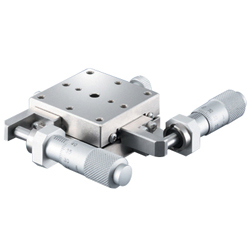

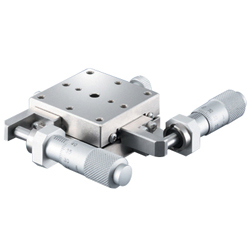

Manual XY-Axis Stages - Linear Ball Guide, Low Profile, Stainless Steel, BSS23

Suruga Seiki

A low profile linear ball guide stage (XY-axis) with an integrated XY-axis structure.[Features]・ Achieved high stiffness and high accuracy by adopting stainless steel as the body material and gothic arch grooves in the guide part.

・ The thickness of the main body can be reduced compared to the single axis combination. ・ Stage sizes available are 40 mm, 50 mm, 60 mm, 70 mm, 80 mm, and 100 mm square

[Applications]・ Ideal for fine positioning as a sample inspection table.

・ Ideal for adjusting the dispenser head.

・ Ideal for CCD camera alignment.- Volume Discount

Days to Ship: 10 Days or more -

Manual XY-Axis Stages - Dovetail, Feed Screw, B08/BDBYR/BDBYS

Suruga Seiki

A feed screw type dovetail stage (XY-axis) with a wide range of sizes and strokes.[Features]・ It is composed of a nut and a feed screw on the main body side, and fine adjustment is possible compared to a rack and a pinion

・ The feed method can be selected from the knob type or the hex key operation type

・ The hex key operation type is space-saving and effective in preventing erroneous operation

[Applications]・ Adjustment of cameras, microscopes, sensors and optical components

・ Positioning of production, assembly and inspection processes related to semiconductors and measuring instruments- Volume Discount

Days to Ship: 8 Days or more -

Suruga Seiki

A linear ball guide stage (XY-axis) that achieves "high stiffness and high accuracy."[Features]・ Achieved high stiffness and high accuracy by adopting stainless steel as the body material and gothic arch grooves in the guide part.

・ The perpendicularity of assembly is within 10 μm.

・ Four types of stage surface sizes are available: 25 × 25 mm, 40 × 40 mm, 60 × 60 mm, and 80 × 80 mm square.

・ The feed position can be selected from the center or the side drive.

・ A wide variety of feeding methods are available.

[Applications]・ Precision adjustment of cameras, microscopes, sensors and optical components

・ Positioning of production, assembly and inspection processes related to semiconductors and measuring instruments- Volume Discount

Days to Ship: 11 Days or more -

Manual XY-Axis Stages - Linear Ball Guide, Low Cost, BYT

Suruga Seiki

A "low price and high stiffness" steel linear ball guide stage (XY-axis).[Features]・ Achieved the low price equivalent to the dovetail stage due to its own production method.

・ The moment stiffness equivalent to that of the SS stage is maintained, and it can be used with confidence even in the center of gravity at the overhang position

[Applications]・ Precision adjustment of cameras, microscopes, sensors and optical components

・ Positioning of production, assembly and inspection processes related to semiconductors and measuring instruments.- Volume Discount

Days to Ship: 13 Days or more

| Brand |

|---|

| Product Series |

| CAD |

| Days to Ship |

| Travel (X Distance) Range(mm) |

| Travel (Y Distance) Range(mm) |

| Load Capacity (Range)(N) |

| Table Size (Length) L (Range)(mm) |

| Table Size (Width) W (Range)(mm) |

| Table Size (Thickness) H (Range)(mm) |

| Feeding Method |

| Guiding Mechanism |

| Table Material |

| Table Surface Treatment |

| Brand | Suruga Seiki | Suruga Seiki | Suruga Seiki | Suruga Seiki | Suruga Seiki | Suruga Seiki | Suruga Seiki | Suruga Seiki | Suruga Seiki |

|---|---|---|---|---|---|---|---|---|---|

| Product Series | Manual XY-Axis Stages - Cross Roller Guide, High Accuracy, Lightweight, B21 | Manual XY-Axis Stages - Cross Roller Guide, Through Hole, B27 | Manual XY-Axis Stages - Linear Ball Guide, Stainless Steel, Electroless Nickel Plating, BSS26 | Manual XY-Axis Stages - Cross Roller Guide, Low Profile, B23 | Manual XY-Axis Stages - Linear Ball Guide, Low Profile, Stainless Steel, BSS23 | Manual XY-Axis Stages - Dovetail, Feed Screw, B08/BDBYR/BDBYS | |||

| CAD |

|

|

|

|

|

|

|

|

|

| Days to Ship | 8 Days or more | 11 Days or more | 8 Days or more | 10 Days or more | 8 Days or more | 10 Days or more | 8 Days or more | 11 Days or more | 13 Days or more |

| Travel (X Distance) Range(mm) | Up to ±10mm / ±10 to 30mm | Up to ±10mm / ±10 to 30mm | Up to ±10mm / ±10 to 30mm | Up to ±10mm / ±10 to 30mm | Up to ±10mm / ±10 to 30mm | Up to ±10mm / ±10 to 30mm | Up to ±10mm | Up to ±10mm / ±10 to 30mm | Up to ±10mm |

| Travel (Y Distance) Range(mm) | Up to ±10mm / ±10 to 30mm | Up to ±10mm / ±10 to 30mm | Up to ±10mm / ±10 to 30mm | Up to ±10mm / ±10 to 30mm | Up to ±10mm / ±10 to 30mm | Up to ±10mm / ±10 to 30mm | Up to ±10mm | Up to ±10mm / ±10 to 30mm | Up to ±10mm |

| Load Capacity (Range)(N) | 5 to 30 / 30.1 to 50 / 50.1 to 100 / 100.1 or More | 5 to 30 | 50.1 to 100 | 30.1 to 50 / 50.1 to 100 / 100.1 or More | 5 to 30 / 30.1 to 50 | 50.1 to 100 / 100.1 or More | 5 to 30 / 30.1 to 50 | 30.1 to 50 / 50.1 to 100 / 100.1 or More | 50.1 to 100 / 100.1 or More |

| Table Size (Length) L (Range)(mm) | Up to 25 ~ 91 to 120 | Up to 25 ~ 41 to 60 | 91 to 120 | Up to 25 ~ 91 to 120 | 26 to 40 ~ 91 to 120 | 26 to 40 ~ 91 to 120 | Up to 25 ~ 41 to 60 | Up to 25 ~ 61 to 90 | 26 to 40 ~ 41 to 60 |

| Table Size (Width) W (Range)(mm) | Up to 25 ~ 91 to 120 | Up to 25 ~ 41 to 60 | 91 to 120 | Up to 25 ~ 91 to 120 | 26 to 40 ~ 91 to 120 | 26 to 40 ~ 91 to 120 | Up to 25 ~ 41 to 60 | Up to 25 ~ 61 to 90 | 26 to 40 ~ 41 to 60 |

| Table Size (Thickness) H (Range)(mm) | 25.1 to 30 ~ 50.1 to 60 | 35.1 to 40 ~ 70.1 to 80 | 25.1 to 30 | 20.1 to 25 ~ 35.1 to 40 | 20.1 to 25 ~ 25.1 to 30 | 20.1 to 25 ~ 25.1 to 30 | 25.1 to 30 ~ 50.1 to 60 | 20.1 to 25 ~ 35.1 to 40 | 35.1 to 40 |

| Feeding Method | Feed Screw / Micrometer Heads | - | - | Feed Screw / Micrometer Heads | - | - | - | Feed Screw / Micrometer Heads | Micrometer Heads |

| Guiding Mechanism | Cross Roller | Dovetail Slide | Cross Roller | Linear Ball | Cross Roller | Linear Ball | Dovetail Slide | Linear Ball | Linear Ball |

| Table Material | Aluminum | Aluminum / Brass | Aluminum | Stainless Steel | Aluminum | Stainless Steel | Aluminum / Brass | Stainless Steel | Steel |

| Table Surface Treatment | Black Anodize | Black Anodize / Black Oxide | Black Anodize | Electroless Nickel | Black Anodize | Electroless Nickel | Black Anodize / Black Oxide | Low Temperature Black Chrome | Electroless Nickel |

Loading...

Configure

Specification/Dimensions

-

Metric / Inch

-

Travel (X Distance) Range(mm)

- Up to ±10mm

- ±10 to 30mm

- ±30mm or More

-

Travel (Y Distance) Range(mm)

- Up to ±10mm

- ±10 to 30mm

- ±30mm or More

-

Load Capacity (Range)(N)

- 1 to 4.9

- 5 to 30

- 30.1 to 50

- 50.1 to 100

- 100.1 or More

-

Table Size (Length) L (Range)(mm)

-

Table Size (Width) W (Range)(mm)

-

Table Size (Thickness) H (Range)(mm)

- 1 to 15

- 15.1 to 20

- 20.1 to 25

- 25.1 to 30

- 30.1 to 35

- 35.1 to 40

- 40.1 to 50

- 50.1 to 60

- 60.1 to 70

- 70.1 to 80

The height is from the bottom to the top of the mounting surface. The micrometer head is not counted for the measurement.

-

Feeding Method

- Rack & Pinion

- Feed Screw

- Micrometer Heads

-

Guiding Mechanism

- Dovetail Slide

- Cross Roller

- Linear Ball

- Slide Guide

- Dovetail, Feed Screw

-

Table Material

- Steel

- Stainless Steel

- Aluminum

- Brass

- Aluminum Alloy

-

Table Surface Treatment

Narrow search by specifying Manufacturer

CAD

-

- 2D

- 3D

How can we improve?

How can we improve?

While we are not able to respond directly to comments submitted in this form, the information will be reviewed for future improvement.

Customer Privacy Policy

Thank you for your cooperation.

While we are not able to respond directly to comments submitted in this form, the information will be reviewed for future improvement.

Please use the inquiry form.

Customer Privacy Policy