(!)Due to Microsoft's end of support for Internet Explorer 11 on 15/06/2022, this site does not support the recommended environment.

Mon. - Fri. 8 a.m. - 6 p.m.

All Categories

Categories

- Automation Components

- Linear Motion

- Rotary Motion

- Connecting Parts

- Rotary Power Transmission

- Motors

- Conveyors & Material Handling

- Locating, Positioning, Jigs & Fixtures

- Inspection

- Sensors, Switches

- Pneumatics, Hydraulics

- Vacuum Components

- Hydraulic Equipment

- Spray Equipment And Accessories

- Pipe, Tubes, Hoses & Fittings

- Modules, Units

- Heaters, Temperature Control

- Aluminum Extrusions, Framing, Support & Posts

- Casters, Leveling Mounts, Posts

- Doors, Cabinet Hardware

- Springs, Shock Absorbers

- Adjustment/Fastening Components, Pins, Magnets

- Antivibration, Soundproofing Materials, Safety Products

- Fasteners

- Materials

- Wiring Components

- LAN Cables / Industrial Network Cables

- Equipment Specific Cables

- Cordsets

- Computer & AV Cables

- Wire/Cable

- Connector (General Purpose)

- Crimp Terminal Components

- Cable Organization

- Cable Gland Components

- Cable Bushing/Clip/Sticker

- Screw/Spacer

- Cable accessories

- Tube

- Electrical Conduits

- Duct/Wiring

- Electrical Wiring Tools

- Dedicated tools

- Soldering supplies

- Electrical & Controls

- Cutting Tools

- Carbide End Mill

- HSS End Mill

- Concrete Drill Bits

- Milling Cutter Insert / Holder

- Core Drill Bits

- Customized Straight Blade End Mill

- Dedicated Cutter

- Crinkey Cutters

- Turning Tool

- Drill

- Cutting Tool Accessories

- Screw Hole Related Tools

- Reamer

- Electric Drill Bits

- Chamfering, Centering Tool

- Hole Saws

- Magnetic Drill Press Cutters

- Step Drills

- Wood Drills & Cutters

- Processing Tools

- packing & logistics storage supplies

- Safety Products

- research and development & cleanroom supplies

- Press Die Components

- Plastic Mold Components

- Ejector Pins

- Sleeves, Center Pins

- Core Pins

- Sprue bushings, Gates, and other components

- Date Mark Inserts, Recycle Mark Inserts, Pins with Gas Vent

- Undercut, Plates

- Leader Components, Components for Ejector Space

- Mold Opening Controllers

- Cooling or Heating Components

- Accessories, Others

- Components of Large Mold, Die Casting

- Injection Molding Components

- Purging Agent

- Injection Molding Machine Products

- Accessories of Equipment

- Auxiliary Equipment

- Air Nippers

- Air Cylinders

- Air Chuck for Runner

- Chuck Board Components

- Frames

- Suction Components

- Parallel Air Chuck

- Special Air Chuck

- Mold Maintenance

- Heating Items

- Heat Insulation Sheets

- Couplers, Plugs, One-touch Joints

- Tubes, Hoses, Peripheral Components

Applications

Brands

- Webcode Seach | Series

-

#CODE

- Discontinued Products

- Scheduled Maintenance Notice: This site will be unavailable due to scheduled maintenance from 5:00 p.m. 3/1 to 4:00 p.m. (CST) 3/2/2025. We apologize for the inconvenience.

Boring Holders(Use:Minor Diameter)

| Days to Ship |

|

|---|

-

VNB Type (Inner Diameter Machined)

KYOCERA

•Use: Minor Diameter

•Preferred Hand: Right Handed

•Dimension H (mm): 3.9- Volume Discount

Days to Ship: 8 Days or more -

EWN Boring Head Set (for Finishing / Insert Holder Type)

DAISHOWASEIKI

•Use: Minor Diameter

•Compatible Tip Shape: T (Triangular)

•Oil Hole Presence: Included

•Description: ENH○-1 is attached to the insert holder. Purchase ENH○-2 and 3 separately. When using with back boring, the direction of rotation is reversed.

•Feature: 1-micron scale has been added to the easy-to-see scale of 0.01 mm/φ increments.- Volume Discount

Days to Ship: 8 Days or more -

SW Boring Head (Rough Highly Rigid Type)

DAISHOWASEIKI

[Features]

· High-rigidity type for roughing. Center through.- Volume Discount

Days to Ship: 10 Days or more -

A/S-SCLC-AE Type Excellent Bar (Inner Diameter / Back End Surface Machining)

KYOCERA

•Use: Minor Diameter

•Compatible Tip Shape: C (80° Diamond)

•Clearance Angle: 7°

•Clamp Shape: Screw On

•Protrusion Length d: ~5.5- Volume Discount

Days to Ship: 8 Days or more -

S-SCLC-A Type Steel Bar (Inner Diameter, Inner End Surface Machining)

KYOCERA

•Use: Minor Diameter

•Compatible Tip Shape: C (80° Diamond)

•Clearance Angle: 7°

•Clamp Shape: Screw On

•Protrusion Length d: Up to 4- Volume Discount

Days to Ship: 8 Days or more -

A/S-STLB (P)-AE Type A/S-STLB (P)-AE Type Excellent Bar (Inner Diameter and Interior Edge Machining)

KYOCERA

•Use: Minor Diameter

•Compatible Tip Shape: T (Triangular)

•Clearance Angle: 11°

•Clamp Shape: Screw On- Volume Discount

Days to Ship: 8 Days or more -

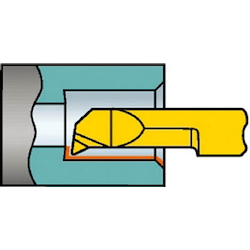

Sandvik CoroTurn 107 Positive Tip Boring Bit AK-SDQCR

SANDVIK

[Features]

· Low cutting resistance inner diameter boring bar.

· Internal coolant extends the tip life and is good for chip processing.

· Capable of stable machining even when machining long protrusion thanks to its high tool rigidity.

· With the easy fix sleeve, accurate and quick core height adjustment is possible.

[Applications]

· For inner diameter turning operations.- Volume Discount

Days to Ship: 16 Days or more -

EWN Boring Head Set (for Finishing / Round Bit Type)

DAISHOWASEIKI

•Use: Minor Diameter

•Minimum Processing Diameter: 1

•Oil Hole Presence: Included

•Feature: Three types of heads suitable for machining can be selected.

•Specification: Ultra-precision head that can be adjusted in microns makes small-diameter boring possible. Extensive carbide cutting tool series that can be used for quick small-diameter deep drilling.- Volume Discount

Days to Ship: 10 Days or more -

Insert Holder For EWN Boring Head Replacement

DAISHOWASEIKI

[Features]

Combining the head and insert holder makes it possible to secure a cutting chip pocket.

Designed for improved cutting chip discharge.

For EWN head- Volume Discount

Days to Ship: 12 Days or more -

S-SWUB (P)-A Type Steel Bar (Inner Diameter Machining)

KYOCERA

•Use: Minor Diameter

•Compatible Tip Shape: W (Hexagonal)

•Clamp Shape: Screw On

•Protrusion Length d: Up to 4

•Dimension S (mm): -- Volume Discount

Days to Ship: 8 Days or more -

Sandvik T-Max P Negative Tip Boring Bit A

SANDVIK

[Features]

· Easy to handle I.D. boring bit with excellent repeatability.

[Applications]

· Inner diameter turning/negative insert supported.

· Support from rough machining to finish machining.- Volume Discount

Days to Ship: 6 Days or more -

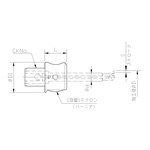

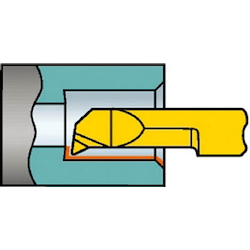

Micro Boring Bit Model CKB (Holder)

SUMITOMO ELEC

Automatic lathes can be supported. High indexing precision. Insert replacement operation is simple.

- Volume Discount

Days to Ship: 9 Days or more -

Micro Boring Bit Model CKB (Square Shank)

SUMITOMO ELEC

Automatic lathes can be supported. High indexing precision. Insert replacement operation is simple.

- Volume Discount

Days to Ship: 8 Days or more -

Micro Boring Bit Model CKB (Circular Shank Offset Small)

SUMITOMO ELEC

Automatic lathes can be supported. High indexing precision. Insert replacement operation is simple.

- Volume Discount

Days to Ship: 9 Days or more -

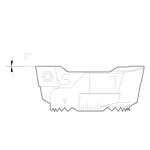

MANYOTOOLS

[Features]

· A rough machining boring head used with a square bit mounted- Volume Discount

Days to Ship: 12 Days or more -

MANYOTOOLS

[Features]

· A rough machining boring head used with a square bit mounted- Volume Discount

Days to Ship: 12 Days or more -

Days to Ship: 12 Days or more -

TBS Throw-Away Square Bit Back Boring

MANYOTOOLS

•Use: Minor Diameter

•Compatible Tip Shape: S (Square)

•Clamp Shape: Screw On

•Type: 90° L Back Boring- Volume Discount

Days to Ship: 13 Days or more -

EWB Boring Head (High-Speed Finishing / Automatic Balance Compensation Mechanism Built-In)

DAISHOWASEIKI

[Features]

· With excellent dynamic balance, it achieves high-speed processing and stable precision.

· Automatic balance compensation.

· Accurate φ0.01 mm unit scale ultra-precision head.- Volume Discount

Days to Ship: 13 Days or more -

EWB Round Bit Boring Head (High-Speed Finishing / Manual Balance Adjustment Mechanism Built-In)

DAISHOWASEIKI

[Features]

· The internal weight can be adjusted manually by turning the balance ring.

· Manual balance adjustment mechanism. 5 μm/φ scale precision diameter adjustment mechanism (EWB2-50 only).- Volume Discount

Days to Ship: 13 Days or more -

DAISHOWASEIKI

[Features]

· Microminiaturized, using the popular φ0.01 mm scale adjustment mechanism.

· Adjustment with only micro-quill eccentricity preserves high speed capability.

· Carbide solid straight shank enables high-rigidity machining.- Volume Discount

Days to Ship: 12 Days or more -

RW Cartridge (for Through Holes) Cartridge Body

DAISHOWASEIKI

•Use: Minor Diameter

•Compatible Tip Shape: S (Square)

•Type: Through Hole A Type

•Description: The cartridges is a set of two and comes with one tip clamp screw wrench.

•Specification: Square tip, 4 corners are usable- Volume Discount

Days to Ship: 10 Days or more -

RW Cartridge (for Blind Holes) Cartridge Body

DAISHOWASEIKI

•Use: Minor Diameter

•Compatible Tip Shape: C (80° Diamond)

•Type: For Blind Hole E Type

•Specification: 80° Diamond-shaped tip; 2 corners can be used- Volume Discount

Days to Ship: 8 Days or more -

SW Cartridge (A-Type for Through Holes)

DAISHOWASEIKI

[Features]

· 4 corners of the tip can be used- Volume Discount

Days to Ship: 10 Days or more -

SW Cartridge (E-Type for Blind Holes)

DAISHOWASEIKI

[Features]

· Compatible with flat seating surface machining- Volume Discount

Days to Ship: 10 Days or more -

TW Cartridge (E-Type for Blind Holes)

DAISHOWASEIKI

[Features]

· 80° diamond-shaped tip; 2 corners can be used- Volume Discount

Days to Ship: 8 Days or more -

![VNB-S Type (Inner Diameter Machined) [Corner R (rε) Flathead Tolerance]](//mx.misumi-ec.com/en/linked/material/fs/KYR1/PHOTO/223005303008.jpg?$product_view_b$)

VNB-S Type (Inner Diameter Machined) [Corner R (rε) Flathead Tolerance]

KYOCERA

•Use: Minor Diameter

•Preferred Hand: Right Handed

•Dimension H (mm): 3.9- Volume Discount

Days to Ship: 8 Days or more -

PSB-S Type (Internal Diameter Machining)

KYOCERA

An insert bar for small inner diameter boring.

Machining applications: Inner diameter / through hole

Reference corner radius (nose radius): 0.05- Volume Discount

Days to Ship: 7 Days or more -

A-SCLP-AE Type Excellent Bar (Inner Diameter / Back End Surface Machining)

KYOCERA

•Use: Minor Diameter

•Compatible Tip Shape: C (80° Diamond)

•Clearance Angle: 11°

•Clamp Shape: Screw On

•Protrusion Length d: ~5.5- Volume Discount

Days to Ship: 8 Days or more -

S-SCLP-A Type Steel Bar (Inner Diameter, Inner End Surface Machining)

KYOCERA

•Use: Minor Diameter

•Compatible Tip Shape: C (80° Diamond)

•Clearance Angle: 11°

•Clamp Shape: Screw On

•Protrusion Length d: Up to 4- Volume Discount

Days to Ship: 8 Days or more -

S/A-SWUB (P)-AE Type Excellent Bar (Inner Diameter Machining)

KYOCERA

•Use: Minor Diameter

•Compatible Tip Shape: W (Hexagonal)

•Clamp Shape: Screw On

•Protrusion Length d: ~5.5

•Dimension S (mm): -- Volume Discount

Days to Ship: 8 Days or more -

CORO-TURN 107 Boring Bit for Positive Tips

SANDVIK

Unique shape exhibits high performance

- Volume Discount

Days to Ship: 6 Days or more -

CORO-TURN RC, Boring Bit for Negative Tips

SANDVIK

Unique shape exhibits high performance

- Volume Discount

Days to Ship: 9 Days or more -

Days to Ship: 7 Days or more -

Days to Ship: 11 Days or more -

Days to Ship: 9 Days or more -

Days to Ship: 6 Days or more -

Boring Tool Bit, CoroTurn 107, Screw Clamp, A...-SDQCR/L

SANDVIK

[Features]

An inner-diameter boring tool bit with low cutting resistance.

The internal coolant helps extend the life of the insert while also making it easier to handle cutting chips.

The high tool rigidity allows for stable machining operations, even with workpieces with long protruding sections.

For inner-diameter turning (bore cutting) operations.- Volume Discount

Days to Ship: 9 Days or more -

Boring Tool Bit, CoroTurn 111, Screw Clamp, A...-SWLPR/L-R, E...-SWLPR/L-R

SANDVIK

[Features]

An inner-diameter boring tool bit with low cutting resistance.

The internal coolant helps extend the life of the insert while also making it easier to handle cutting chips.

The high tool rigidity allows for stable machining operations, even with workpieces with long protruding sections.

For inner-diameter turning (bore cutting) operations.- Volume Discount

Days to Ship: 15 Days or more -

CoroTurn XS Insert Bar for Turning CXS-..T098

SANDVIK

[Features]

CoroTurn XS, Insert Bar

Coating Carbide

Boring Bar for Small Diameter Machining

For lathe turning- Volume Discount

Days to Ship: 8 Days or more -

Cartridge T-Max P Lever Clamp For Negative Inserts PTFNR/L

SANDVIK

Turning tool cartridge

High-productivity external turning T-Max P series for large to medium-sized parts- Volume Discount

Days to Ship: 11 Days or more -

Kyocera Boring Bit Holder A32S-DTFNR16-40

KYOCERA

•Use: Minor Diameter

•Clamp Shape: Cable clamp

•JAN Code: 4960664730933

•Trusco Code: 771-9701

•Compatible Tip: Compatible Tip: TN○○1604- Volume Discount

Days to Ship: 11 Days or more -

Sandvik CoroTurn 107 Positive Tip Boring Bit A-SDQCR

SANDVIK

[Features]

· Low cutting resistance inner diameter boring bar.

· Internal coolant extends the tip life and is good for chip processing.

· Capable of stable machining even when machining long protrusion thanks to its high tool rigidity.

[Applications]

· For inner diameter turning operations.- Volume Discount

Days to Ship: Quote -

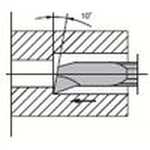

Sandvik CoroTurn 107 Positive Tip Carbide Boring Bit

SANDVIK

[Features]

· A bit dedicated for deep hole boring, with an anti-vibration device for absorbing cutting vibration caused by the tool built into the bit.

· Dynamic rigidity of the anti-vibration bit is greatly enhanced by the cutting vibration damping capability of the anti-vibration device inside the bit. Regular steel boring bar projection length limit is 4 times the tool diameter, but this allows the projection length to be extended to about 7 times.

[Applications]

· For inside turning of long protrusions.

· To prevent chattering.- Volume Discount

Days to Ship: Quote -

Kyocera Boring Bit Holder A25R-DCLNR12-32

KYOCERA

•Use: Minor Diameter

•Clamp Shape: Cable clamp

•JAN Code: 4960664730797

•Trusco Code: 771-9663

•Compatible Tip: Compatible Tip: CN○○1204- Volume Discount

Days to Ship: 9 Days or more

| Brand |

|---|

| Product Series |

| Days to Ship |

| Applicable Tip Shape |

| Minimum Processing Diameter |

| Use |

| Preferred Hand |

| Clamp Shape |

| Overall Length L1 |

| Clearance Angle |

| Link Diameter |

| Protrusion Length (L/D) |

| Oil Hole Presence |

| Brand | KYOCERA | DAISHOWASEIKI | DAISHOWASEIKI | KYOCERA | KYOCERA | KYOCERA | SANDVIK | DAISHOWASEIKI | DAISHOWASEIKI | KYOCERA | SANDVIK | SUMITOMO ELEC | SUMITOMO ELEC | SUMITOMO ELEC | MANYOTOOLS | MANYOTOOLS | MANYOTOOLS | MANYOTOOLS | DAISHOWASEIKI | DAISHOWASEIKI | DAISHOWASEIKI | DAISHOWASEIKI | DAISHOWASEIKI | DAISHOWASEIKI | DAISHOWASEIKI | DAISHOWASEIKI | KYOCERA | KYOCERA | KYOCERA | KYOCERA | KYOCERA | SANDVIK | SANDVIK | SANDVIK | SANDVIK | SANDVIK | SANDVIK | SANDVIK | SANDVIK | SANDVIK | SANDVIK | KYOCERA | SANDVIK | SANDVIK | KYOCERA |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Product Series | A/S-SCLC-AE Type Excellent Bar (Inner Diameter / Back End Surface Machining) | S-SCLC-A Type Steel Bar (Inner Diameter, Inner End Surface Machining) | A/S-STLB (P)-AE Type A/S-STLB (P)-AE Type Excellent Bar (Inner Diameter and Interior Edge Machining) | EWB Boring Head (High-Speed Finishing / Automatic Balance Compensation Mechanism Built-In) | EWB Round Bit Boring Head (High-Speed Finishing / Manual Balance Adjustment Mechanism Built-In) | VNB-S Type (Inner Diameter Machined) [Corner R (rε) Flathead Tolerance] | A-SCLP-AE Type Excellent Bar (Inner Diameter / Back End Surface Machining) | S-SCLP-A Type Steel Bar (Inner Diameter, Inner End Surface Machining) | S/A-SWUB (P)-AE Type Excellent Bar (Inner Diameter Machining) | Boring Tool Bit, CoroTurn 111, Screw Clamp, A...-SWLPR/L-R, E...-SWLPR/L-R | |||||||||||||||||||||||||||||||||||

| Days to Ship | 8 Days or more | 8 Days or more | 10 Days or more | 8 Days or more | 8 Days or more | 8 Days or more | 16 Days or more | 10 Days or more | 12 Days or more | 8 Days or more | 6 Days or more | 9 Days or more | 8 Days or more | 9 Days or more | 12 Days or more | 12 Days or more | 12 Days or more | 13 Days or more | 13 Days or more | 13 Days or more | 12 Days or more | 10 Days or more | 8 Days or more | 10 Days or more | 10 Days or more | 8 Days or more | 8 Days or more | 7 Days or more | 8 Days or more | 8 Days or more | 8 Days or more | 6 Days or more | 9 Days or more | 7 Days or more | 11 Days or more | 9 Days or more | 6 Days or more | 9 Days or more | 15 Days or more | 8 Days or more | 11 Days or more | 11 Days or more | Quote | Quote | 9 Days or more |

| Applicable Tip Shape | - | T (Triangular) | - | C (80° Diamond) | C (80° Diamond) | T (Triangular) | - | - | T (Triangular) | W (Hexagonal) | - | - | - | Others | - | - | T (Triangular) / S (Square) | S (Square) | T (Triangular) | T (Triangular) | W (Hexagonal) | S (Square) | C (80° Diamond) | C (80° Diamond) | C (80° Diamond) / D (55° Diamond) | C (80° Diamond) | - | - | C (80° Diamond) | C (80° Diamond) | W (Hexagonal) | C (80° Diamond) | C (80° Diamond) | C (80° Diamond) | D (55° Diamond) | - | - | T (Triangular) | W (Hexagonal) | - | T (Triangular) | - | - | - | - |

| Minimum Processing Diameter | 3 ~ 7 | 20 ~ 100 | 20 ~ 148 | 7 | 27 | 8 | - | 1 | - | 18 | - | - | - | - | 50 ~ 130 | 50 ~ 130 | - | - | 32 ~ 85 | 1 | 15 ~ 18 | 25 ~ 125 | 25 ~ 125 | 20 ~ 175 | 20 ~ 175 | 25 | 1 ~ 4 | 4 | 14 ~ 18 | 27 | 8 | 20 ~ 25 | 32 | 40 ~ 80 | 50 ~ 80 | - | 20 ~ 32 | 55 | 6.5 | 0.3 ~ 7.2 | 55 | - | - | - | - |

| Use | Minor Diameter | Minor Diameter | Minor Diameter | Minor Diameter | Minor Diameter | Minor Diameter | Minor Diameter | Minor Diameter | Minor Diameter | Minor Diameter | Minor Diameter | Minor Diameter | Minor Diameter | Minor Diameter | Minor Diameter | Minor Diameter | Minor Diameter | Minor Diameter | Minor Diameter | Minor Diameter | Minor Diameter | Minor Diameter | Minor Diameter | Minor Diameter | Minor Diameter | Minor Diameter | Minor Diameter | Minor Diameter | Minor Diameter | Minor Diameter | Minor Diameter | Minor Diameter | Minor Diameter | Minor Diameter | Minor Diameter | Minor Diameter | Minor Diameter | Minor Diameter | Minor Diameter | Minor Diameter | Minor Diameter | Minor Diameter | Minor Diameter | Minor Diameter | Minor Diameter |

| Preferred Hand | Right Handed | - | - | Right Handed | Right Handed | Right Handed | - | - | - | Left Handed | - | Right Handed | Right Handed | - | - | - | - | - | - | - | - | - | - | - | - | - | Right Handed | Left Handed | Right Handed | Left Handed | Right Handed | Right Handed / Left Handed | Right Handed | Right Handed / Left Handed | Right Handed / Left Handed | Right Handed / Left Handed | - | Right Handed | Left Handed | Right Handed / Left Handed | Right Handed | - | - | - | - |

| Clamp Shape | - | - | - | Screw On | Screw On | Screw On | - | - | - | Screw On | - | - | - | - | - | - | Screw On | Screw On | - | - | - | - | - | - | - | - | - | - | Screw On | Screw On | Screw On | Screw On | Cable clamp | - | - | - | - | Lever Lock | Screw On | - | Lever Lock | Cable clamp | - | - | Cable clamp |

| Overall Length L1 | 30.8 ~ 39.8 | - | - | 100 | 250 | 100 | - | - | - | 180 | - | 125 | 100 | 100 | - | - | 80 ~ 150 | 80 ~ 140 | - | - | 144 ~ 204 | - | - | - | - | - | 26.5 ~ 39.8 | 60 | 150 ~ 180 | 250 | 100 | 200 ~ 250 | 300 | 32 ~ 40 | 32 ~ 40 | 113.65 ~ 154 | 105 ~ 200 | 63 | 80 | 27.25 ~ 72.25 | 63 | - | - | - | - |

| Clearance Angle | - | - | - | 7° | 7° | 11° | - | - | - | 11° | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | 11° | 11° | 5° | 7° | 0° | - | - | - | - | - | 11° | - | - | - | - | - | - |

| Link Diameter | - | - | - | 10 | 25 | 6 | - | - | - | 16 | - | - | - | 25.4 | 16 ~ 42 | 16 ~ 42 | - | - | - | 50 ~ 63.5 | 14 ~ 16 | - | - | - | - | - | - | 3.8 | 12 ~ 16 | 25 | 10 | 16 ~ 20 | 25 | 32 ~ 60 | 40 ~ 60 | 32 ~ 40 | 16 ~ 25 | - | 5 | 4 ~ 7 | - | - | - | - | - |

| Protrusion Length (L/D) | - | - | - | ~5.5 | Up to 4 | Up to 4 | - | - | - | Up to 4 | - | - | - | - | - | - | - | - | - | - | 100 ~ 160 | - | - | - | - | - | - | - | ~5.5 | Up to 4 | ~5.5 | 24~64 ~ 30~80 | 37.5~100 | - | - | - | 64 ~ 100 | - | 7.5 to 20 | - | - | - | - | - | - |

| Oil Hole Presence | - | Included | Included | None | None | None | - | Included | - | None | - | None | None | None | - | - | - | - | Included | Included | Included | None | None | None | None | None | - | - | Included | None | None | Included | Included | Included | Included | Included | Included | None | Included | None | None | - | - | - | - |

Loading...

Configure

Specification/Dimensions

-

Applicable Tip Shape

-

Metric / Inch

- metric

-

Minimum Processing Diameter

-

Use

- Minor Diameter

- Inner Diameter Profile

-

Preferred Hand

- Right Handed

- Left Handed

-

Clamp Shape

- Cable clamp

- Screw On

- Lever Lock

-

Overall Length L1

-

Clearance Angle

- 5°

- 7°

- 0°

- 11°

-

Link Diameter

-

Protrusion Length (L/D)

-

Oil Hole Presence

Narrow search by specifying Manufacturer

CAD

-

- 2D

- 3D

![VNB-S Type (Inner Diameter Machined) [Corner R (rε) Flathead Tolerance]](http://mx.misumi-ec.com/en/linked/material/fs/KYR1/PHOTO/223005303008.jpg?$product_view_b$)

![VNB-S Type (Inner Diameter Machined) [Corner R (rε) Flathead Tolerance]](http://mx.misumi-ec.com/en/linked/material/fs/KYR1/PHOTO/223005303008.jpg?$product_view_c$)

How can we improve?

How can we improve?

While we are not able to respond directly to comments submitted in this form, the information will be reviewed for future improvement.

Customer Privacy Policy

Thank you for your cooperation.

While we are not able to respond directly to comments submitted in this form, the information will be reviewed for future improvement.

Please use the inquiry form.

Customer Privacy Policy