(!)Due to Microsoft's end of support for Internet Explorer 11 on 15/06/2022, this site does not support the recommended environment.

Mon. - Fri. 8 a.m. - 6 p.m.

All Categories

-

Automation Components

Automation Components

Show all categories of Automation Components-

Linear Motion

-

Rotary Motion

-

Connecting Parts

-

Rotary Power Transmission

-

Motors

-

Conveyors & Material Handling

-

Locating, Positioning, Jigs & Fixtures

-

Inspection

-

Sensors, Switches

-

Pneumatics, Hydraulics

-

Vacuum Components

-

Hydraulic Equipment

-

Spray Equipment And Accessories

-

Pipe, Tubes, Hoses & Fittings

-

Modules, Units

-

Heaters, Temperature Control

-

Aluminum Extrusions, Framing, Support & Posts

-

Casters, Leveling Mounts, Posts

-

Doors, Cabinet Hardware

-

Springs, Shock Absorbers

-

Adjustment/Fastening Components, Pins, Magnets

-

Antivibration, Soundproofing Materials, Safety Products

-

- Fasteners

- Materials

-

Wiring Components

Wiring Components

Show all categories of Wiring Components-

LAN Cables / Industrial Network Cables

-

Equipment Specific Cables

-

Cordsets

-

Computer & AV Cables

-

Wire/Cable

-

Connector (General Purpose)

-

Crimp Terminal Components

-

Cable Organization

-

Cable Gland Components

-

Cable Bushing/Clip/Sticker

-

Screw/Spacer

-

Cable accessories

-

Tube

-

Electrical Conduits

-

Duct/Wiring

-

Electrical Wiring Tools

-

Dedicated tools

-

Soldering supplies

-

- Electrical & Controls

-

Cutting Tools

Cutting Tools

Show all categories of Cutting Tools-

Carbide End Mill

-

HSS End Mill

-

Concrete Drill Bits

-

Milling Cutter Insert / Holder

-

Core Drill Bits

-

Customized Straight Blade End Mill

-

Dedicated Cutter

-

Crinkey Cutters

-

Turning Tool

-

Drill

-

Cutting Tool Accessories

-

Screw Hole Related Tools

-

Reamer

-

Electric Drill Bits

-

Chamfering, Centering Tool

-

Hole Saws

-

Magnetic Drill Press Cutters

-

Step Drills

-

Wood Drills & Cutters

-

-

Processing Tools

- Packing & Logistics Storage Supplies

- Safety Products

-

Research and Development & Cleanroom Supplies

Research and Development & Cleanroom Supplies

Show all categories of Research and Development & Cleanroom Supplies - Press Die Components

-

Plastic Mold Components

Plastic Mold Components

Show all categories of Plastic Mold Components-

Ejector Pins

-

Sleeves, Center Pins

-

Core Pins

-

Sprue bushings, Gates, and other components

-

Date Mark Inserts, Recycle Mark Inserts, Pins with Gas Vent

-

Undercut, Plates

-

Leader Components, Components for Ejector Space

-

Mold Opening Controllers

-

Cooling or Heating Components

-

Accessories, Others

-

Components of Large Mold, Die Casting

-

-

Injection Molding Components

Injection Molding Components

Show all categories of Injection Molding Components-

Purging Agent

-

Injection Molding Machine Products

-

Accessories of Equipment

-

Auxiliary Equipment

-

Air Nippers

-

Air Cylinders

-

Air Chuck for Runner

-

Chuck Board Components

-

Frames

-

Suction Components

-

Parallel Air Chuck

-

Special Air Chuck

-

Mold Maintenance

-

Heating Items

-

Heat Insulation Sheets

-

Couplers, Plugs, One-touch Joints

-

Tubes, Hoses, Peripheral Components

-

- Webcode Seach | Series

-

#CODE

- Discontinued Products

Loading...

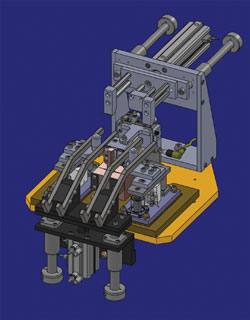

Case Study: Shiroki North America

Shiroki North America Builds Its Own Automotive Production Machinery Using MISUMI Configurable Components

In-house machine building of customer manufacturing jigs leads company to

higher productivity and "the biggest cost savings in our history"

Shiroki North America, Inc. is a premier manufacturer of automobile seat tracks and adjusters, window regulators, doorframes and door sash, which are sold to automotive OEMs and their top tier suppliers. Key customers include: Toyota Engineering and Manufacturing, Toyota Boshoku America, Nissan, Mitsubishi, Subaru-Indiana, Total Interior Systems-America, Johnson Controls, and NHK Spring Co., Ltd.

For half a century, the firm's parent company − Shiroki Corporation of Japan − has been a global leader in automotive manufacturing. It has built a reputation for top-quality craftsmanship combined with advanced technologies and automation processes designed to improve product quality, increase productivity and reduce waste, while respecting the environment.

Standardization of Machine Design/Build Operations

One concept Shiroki has initiated is an in-house machine design/build engineering process, based on standardization of tooling and die parts used in production jigs for mass manufacture of various customer products. In Japan, Shiroki typically sourced many of these types of components from MISUMI Corporation. It has continued this practice in North America by ordering fixed and configurable factory automation and motion control components directly from Illinois-based MISUMI USA to achieve its in-house design/build goals.

Brandon Johnson, Assistant General Manager, Engineering and Maintenance for Shiroki North America explains how this standardization concept works, and how it provides value for both his company and its customers.

"On the automation side, MISUMI components are utilized in virtually all new production jigs we design," notes Johnson. "However, the largest quantity of MISUMI components that we purchase are used as spare and replacement parts for existing production jigs, as part of our ongoing quality control and maintenance operations. The reason is that, once our engineers design a part to the precise dimensions and specifications required, that part is standardized to help us save time and control costs, and MISUMI assigns it a unique product number, which greatly facilitates re-ordering."

Johnson notes that since MISUMI's lead and delivery times are very short, Shiroki North America does not need to maintain an abundance of inventory on its spare and replacement parts, which also helps to hold down costs.

Configurability a Major Factor in Tool and Die Standardization

In designing new production jigs for customer products, Shiroki North America's engineering team, which uses SolidWorks as the design platform, finds that MISUMI's ability to configure components to exacting dimensions and specifications is a huge benefit.

"This capability has been helpful in reducing the need for time- and labor-intensive fabrication of custom parts, whether in-house or by an outside supplier," explains Johnson. "Also MISUMI's CAD support, which offers automatic download of native CAD files, is a big plus for our engineers because it means we do not have to spend time drawing components − or pay an outside supplier to draw them."

Electrical panels also play an integral role in the products manufactured by Shiroki North America, whether for window regulators or seat adjustment mechanisms. For many electrical panel building components – such as wire duct, terminals, and overall enclosures – the company also turns to MISUMI's print catalog and Web ordering system.

Whether for standardized automation tools and dies, replacement parts, or electrical panel components, Shiroki North America has found that MISUMI's business model, cost competitiveness and flexibility complements its own processes and practices and has contributed significantly to its corporate objectives.

"As a mass production manufacturer and supplier itself, MISUMI appreciates our position and works with us to meet our customers' needs and expectations. As a result, our partnership with MISUMI has enabled us to build a sizable machine development group and actually manufacture the machines within our own company, rather than undertake the time, hassle and expense of outsourcing. This initiative has, in fact, led our company to the largest cost savings in our history," Johnson concludes.

About Shiroki North America

Shiroki North America (www.shiroki-na.com) came to these shores in 1988 to provide a convenient supply source of high quality auto parts and assemblies for US-manufactured vehicles. Today, the company employs about 500 people and has a total of 238,000 sq ft of space in its manufacturing plants in Dalton, Georgia, and Smithville and Gordonsville, Tennessee, while continuing to support operations in Japan, China and Thailand.