(!)Due to Microsoft's end of support for Internet Explorer 11 on 15/06/2022, this site does not support the recommended environment.

Mon. - Fri. 8 a.m. - 6 p.m.

All Categories

-

Automation Components

Automation Components

Show all categories of Automation Components-

Linear Motion

-

Rotary Motion

-

Connecting Parts

-

Rotary Power Transmission

-

Motors

-

Conveyors & Material Handling

-

Locating, Positioning, Jigs & Fixtures

-

Inspection

-

Sensors, Switches

-

Pneumatics, Hydraulics

-

Vacuum Components

-

Hydraulic Equipment

-

Spray Equipment And Accessories

-

Pipe, Tubes, Hoses & Fittings

-

Modules, Units

-

Heaters, Temperature Control

-

Aluminum Extrusions, Framing, Support & Posts

-

Casters, Leveling Mounts, Posts

-

Doors, Cabinet Hardware

-

Springs, Shock Absorbers

-

Adjustment/Fastening Components, Pins, Magnets

-

Antivibration, Soundproofing Materials, Safety Products

-

- Fasteners

- Materials

-

Wiring Components

Wiring Components

Show all categories of Wiring Components-

LAN Cables / Industrial Network Cables

-

Equipment Specific Cables

-

Cordsets

-

Computer & AV Cables

-

Wire/Cable

-

Connector (General Purpose)

-

Crimp Terminal Components

-

Cable Organization

-

Cable Gland Components

-

Cable Bushing/Clip/Sticker

-

Screw/Spacer

-

Cable accessories

-

Tube

-

Electrical Conduits

-

Duct/Wiring

-

Electrical Wiring Tools

-

Dedicated tools

-

Soldering supplies

-

- Electrical & Controls

-

Cutting Tools

Cutting Tools

Show all categories of Cutting Tools-

Carbide End Mill

-

HSS End Mill

-

Concrete Drill Bits

-

Milling Cutter Insert / Holder

-

Core Drill Bits

-

Customized Straight Blade End Mill

-

Dedicated Cutter

-

Crinkey Cutters

-

Turning Tool

-

Drill

-

Cutting Tool Accessories

-

Screw Hole Related Tools

-

Reamer

-

Electric Drill Bits

-

Chamfering, Centering Tool

-

Hole Saws

-

Magnetic Drill Press Cutters

-

Step Drills

-

Wood Drills & Cutters

-

-

Processing Tools

- Packing & Logistics Storage Supplies

- Safety Products

-

Research and Development & Cleanroom Supplies

Research and Development & Cleanroom Supplies

Show all categories of Research and Development & Cleanroom Supplies - Press Die Components

-

Plastic Mold Components

Plastic Mold Components

Show all categories of Plastic Mold Components-

Ejector Pins

-

Sleeves, Center Pins

-

Core Pins

-

Sprue bushings, Gates, and other components

-

Date Mark Inserts, Recycle Mark Inserts, Pins with Gas Vent

-

Undercut, Plates

-

Leader Components, Components for Ejector Space

-

Mold Opening Controllers

-

Cooling or Heating Components

-

Accessories, Others

-

Components of Large Mold, Die Casting

-

-

Injection Molding Components

Injection Molding Components

Show all categories of Injection Molding Components-

Purging Agent

-

Injection Molding Machine Products

-

Accessories of Equipment

-

Auxiliary Equipment

-

Air Nippers

-

Air Cylinders

-

Air Chuck for Runner

-

Chuck Board Components

-

Frames

-

Suction Components

-

Parallel Air Chuck

-

Special Air Chuck

-

Mold Maintenance

-

Heating Items

-

Heat Insulation Sheets

-

Couplers, Plugs, One-touch Joints

-

Tubes, Hoses, Peripheral Components

-

- Webcode Seach | Series

-

#CODE

- Discontinued Products

Loading...

Case Study: Orbitform

Orbitform Provides First-Class Machine "Solutions Delivered"

Engineers cite time and cost savings by utilizing MISUMI USA

configurable mechanical components

and powerful 3D CAD configurator

Orbitform Provides First-Class Machine "Solutions Delivered"

Founded in 1980 as a manufacturer of orbital riveting machines, Orbitform Group has evolved over time to become a premier manufacturer of standard and custom forming, fastening and assembly machinery. Orbitform grew by acquiring companies that complemented its own core competencies, and by adopting a philosophy of "Solutions Delivered" to reinforce the company's commitment to excellence of products and customer service.

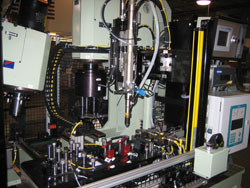

Rear of a flexible automated assembly system built

by OrbitForm Group that utilizes MISUMI product.

According to Daniel Shirkey, manager of Orbitform's Business Development Team, this solution-driven, customer-centric philosophy has become intrinsic to Orbitform's corporate culture and serves as a strong motivator for the 55 employees who work in the company's 110,000-square- foot facility in Jackson, Michigan.

Another important key to Orbitform Group's success is its staff of highly qualified design engineers who are always looking for innovative ways to improve productivity and profitability, while maintaining the high levels of product quality and service customers expect and deserve.

Today, Orbitform Group designs and builds precision machinery for Orbital and Spiral Forming, Impact Riveting, Rollerforming, Welding Automation, Conveyors and Custom Machines for manufacturers in a multitude of industries, including:

- Automotive (seats, hinges, transmissions)

- Heavy equipment (for Agriculture, Construction and Mining)

- Furniture (recliners, beds)

- Medical (surgical devices, flared tubes, casters)

- Safety (fire suppression sprinklers)

- Alternative Energy (lithium batteries, wind devices)

- Aviation (brakes, hose clamps)

- CNC Metal Cutting (automating with palletized and low-back-pressure conveyors)

The complexity involved in designing and building standard and customized machinery for such a diverse array of industries and applications would be challenging for any company's design engineers. To better manage its wide range of complex customer projects, Shirkey notes that Orbitform Group's engineering team leaders are willing and able to deploy proven, cost-effective solutions that can help them improve the design process while, at the same time, reducing engineering time and costs.

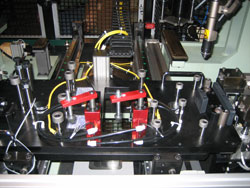

Automatic probe and change over tooling pallets

designed by OrbitForm Group.

Shirkey explains: "For example, our engineers use Dassault Systèmes SolidWorks' 3D CAD technology to design and document during the engineering phase of the project. And, in customizing mechanical parts for various machine building projects, they often specify precision-made and configurable components from MISUMI USA. In sourcing from MISUMI over the past four or five years, we have been extremely satisfied with the quality of the components, as well as the time- and cost-saving advantages realized."

As evidence of this, Shirkey offers a representative sampling of insights gleaned from Orbitform Group's engineering team leaders who regularly specify MISUMI components in designing and engineering their customer projects.

One team used MISUMI components in a project involving an Orbital Riveter Bench machine with a clamshell clamping fixture for forming of a striker assembly, and also in systems involving Orbital Riveters, Welders, Robots and Conveyors. Engineers on this team routinely compare the time and cost of buying MISUMI mechanical components as opposed to designing and making specialized components in-house. This exercise is time well spent, especially when designing standard machines requiring customized automation and fixturing elements. The in-house versus MISUMI decisions are made on a case-by-case basis, based on the specific application requirements.

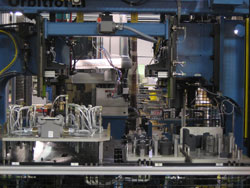

OrbitForm fixturing utilizing eccentric cam location

and swing clamps to secure parts in place.

"We frequently order tooling components from MISUMI, including shafts, couplers, hard stops, bearings and sheet metal," states one engineer on this team. "They can be ordered in various standard sizes and many are configurable. All are typically available within one week – which is very convenient – at a cost significantly less than if we were to design and make the detailed custom parts ourselves."

He also cites MISUMI's 3D CAD Configurator as a useful and valuable tool for saving time and streamlining workflow. "The time we save by downloading the model instead of having to create a detailed drawing in-house helps to shorten the overall duration of the design process. We estimate these downloads typically result in cost savings amounting to 15 to 40 percent and time savings in the 50 percent range. That's quite a significant benefit," said the engineer.

Shirkey related insights from another Orbitform Group engineering team that has had a similar experience with selecting MISUMI components. This group typically orders parts required for fixture designs, including brackets, mounting components and the like – all of which can be found in MISUMI's indexed catalog of more than 500,000 components, as well as in its Web-based e-catalog, complete with dimensions, pricing and delivery times.

"That engineering team leader told me that sourcing these parts from MISUMI has helped save both time and costs throughout the design phase of the project. The overall consensus of Orbitform Group engineers is that the CAD Configurator is one of the biggest benefits of doing business with MISUMI. It's a great competitive advantage," Shirkey concludes.

Orbitform Customer Contact:

Daniel Shirkey, Manager – Business Development Team

Orbitform Group, Jackson, MI

Tel: 517.787.9447 x242

Company URL: www.Orbitform.com