(!)Due to Microsoft's end of support for Internet Explorer 11 on 15/06/2022, this site does not support the recommended environment.

Mon. - Fri. 8 a.m. - 6 p.m.

All Categories

-

Automation Components

Automation Components

Show all categories of Automation Components-

Linear Motion

-

Rotary Motion

-

Connecting Parts

-

Rotary Power Transmission

-

Motors

-

Conveyors & Material Handling

-

Locating, Positioning, Jigs & Fixtures

-

Inspection

-

Sensors, Switches

-

Pneumatics, Hydraulics

-

Vacuum Components

-

Hydraulic Equipment

-

Spray Equipment And Accessories

-

Pipe, Tubes, Hoses & Fittings

-

Modules, Units

-

Heaters, Temperature Control

-

Aluminum Extrusions, Framing, Support & Posts

-

Casters, Leveling Mounts, Posts

-

Doors, Cabinet Hardware

-

Springs, Shock Absorbers

-

Adjustment/Fastening Components, Pins, Magnets

-

Antivibration, Soundproofing Materials, Safety Products

-

- Fasteners

- Materials

-

Wiring Components

Wiring Components

Show all categories of Wiring Components-

LAN Cables / Industrial Network Cables

-

Equipment Specific Cables

-

Cordsets

-

Computer & AV Cables

-

Wire/Cable

-

Connector (General Purpose)

-

Crimp Terminal Components

-

Cable Organization

-

Cable Gland Components

-

Cable Bushing/Clip/Sticker

-

Screw/Spacer

-

Cable accessories

-

Tube

-

Electrical Conduits

-

Duct/Wiring

-

Electrical Wiring Tools

-

Dedicated tools

-

Soldering supplies

-

- Electrical & Controls

-

Cutting Tools

Cutting Tools

Show all categories of Cutting Tools-

Carbide End Mill

-

HSS End Mill

-

Concrete Drill Bits

-

Milling Cutter Insert / Holder

-

Core Drill Bits

-

Customized Straight Blade End Mill

-

Dedicated Cutter

-

Crinkey Cutters

-

Turning Tool

-

Drill

-

Cutting Tool Accessories

-

Screw Hole Related Tools

-

Reamer

-

Electric Drill Bits

-

Chamfering, Centering Tool

-

Hole Saws

-

Magnetic Drill Press Cutters

-

Step Drills

-

Wood Drills & Cutters

-

-

Processing Tools

- Packing & Logistics Storage Supplies

- Safety Products

-

Research and Development & Cleanroom Supplies

Research and Development & Cleanroom Supplies

Show all categories of Research and Development & Cleanroom Supplies - Press Die Components

-

Plastic Mold Components

Plastic Mold Components

Show all categories of Plastic Mold Components-

Ejector Pins

-

Sleeves, Center Pins

-

Core Pins

-

Sprue bushings, Gates, and other components

-

Date Mark Inserts, Recycle Mark Inserts, Pins with Gas Vent

-

Undercut, Plates

-

Leader Components, Components for Ejector Space

-

Mold Opening Controllers

-

Cooling or Heating Components

-

Accessories, Others

-

Components of Large Mold, Die Casting

-

-

Injection Molding Components

Injection Molding Components

Show all categories of Injection Molding Components-

Purging Agent

-

Injection Molding Machine Products

-

Accessories of Equipment

-

Auxiliary Equipment

-

Air Nippers

-

Air Cylinders

-

Air Chuck for Runner

-

Chuck Board Components

-

Frames

-

Suction Components

-

Parallel Air Chuck

-

Special Air Chuck

-

Mold Maintenance

-

Heating Items

-

Heat Insulation Sheets

-

Couplers, Plugs, One-touch Joints

-

Tubes, Hoses, Peripheral Components

-

- Webcode Seach | Series

-

#CODE

- Discontinued Products

Loading...

Case Study: Genesis Automation Returns to Its Roots

GENESIS AUTOMATION RETURNS TO ITS ROOTS…

THE JOY OF ENGINEERING

Key supplier enables company to better utilize talents

GENESIS AUTOMATION RETURNS TO ITS ROOTS… THE JOY OF ENGINEERING

Scott Hale and Chris Reinert, the respective president and director of operations at Genesis Automation, say it best and almost in unison. "Our life sentence in business is doing what we love to do." For this custom designer and builder of automated assembly, test and special process machinery in St. Charles, Illinois, there could be no better situation. Since its founding by Scott Hale in 1999, after he left a long and successful career as president of another automated assembly system builder, Genesis Automation has remained focused on its core commitment to building high-quality, high-precision solutions to the production and test challenges its customers present them. Currently working in the automotive, consumer electronic, pharmaceutical, appliance, telecommunication, fiber optic and emerging nanotechnology markets, Genesis has established itself as a leading supplier of engineered solutions to application-specific requirements. "What that means," as Hale observes, "is that we don't simply take the labor out of labor-intensive jobs. Rather, we seek out projects where specific and often highly complex assembly or production operations need to be performed with extreme accuracy, often in tandem with in-process, in-line or stand-alone testing devices for quality assurance."

"What this does not mean," as Chris Reinert notes, "is that we reinvent ourselves on every job we do. Quite the opposite, really, as we seek to capitalize on the resident technology knowhow, the extreme flexibility of our engineering talent and the highly developed engineering and project tracking data bases we maintain of parts, structures, robotic articulation devices and even proprietary testing strategies we've developed for solving customer challenges in the past." This knowledge warehouse is brought forth and applied to every job at Genesis, according to Reinert.

By doing so, adds Hale, "We get to return to what we enjoy doing most, providing technically advanced solutions that will help our customers compete in an increasingly competitive global market. We actually come to work and have fun doing what we do," muses Hale.

As these two driving forces behind Genesis Automation quickly observe, the company has succeeded and continues to remain ahead of the curve in its industries because of the alliances it's formed with a number of vendors, who each bring their own engineering expertise and problem-solving capabilities to assist Genesis. One such vendor, according to Reinert, is MISUMI USA, a key supplier of factory automation and mechanical assembly components to Genesis. Through the use of the MISUMI catalog, components can be sourced in a slightly different manner. This results from the MISUMI CAD Configurator, a unique service, according to Mike Ricketts, the MISUMI account manager for Genesis. Mike explains, "When a shaft, coupling, ballscrew or just a standoff or hex post is needed, the Genesis engineers can look through the print or online catalog, configure the part needed, then import a CAD drawing into a prototype assembly or test station. But, that's just the beginning of the process." MISUMI enables the customer, when needed, to configure various dimensions of a part to suit a particular need. This is important to Genesis, as many of their customers operate in strictly controlled environments that can range from Class 100 clean-rooms to ultra harsh environments utilizing highly corrosive liquids, where a low-temp black chrome plating or RoHS compliance or merely a simple modification of a component's fastening mechanism might be needed. As Ricketts notes, "Having all these available options with configurable components makes the design engineering job at Genesis easier and faster."

These upsides also extend to the cost, both in design time and actual component investments for Genesis. On a typical machine section, for example, the MISUMI business model allows Genesis to configure components, download native CAD files for importing into their assemblies, then check the fit, confirm the assembly and place orders for parts, all online. Reinert notes the savings in project design time alone through this system often reach into hundreds of hours. Beyond that, he states that the actual cost of the delivered, configured component from MISUMI can be considerably less than producing the parts in their own machine shop at Genesis. This situation has proven very beneficial for the builder, as its machine shop is now focused on more complex parts and substructure production.

Furthermore, through the MISUMI engineering data file, Genesis engineers can maintain a library of parts used on every project. The tracking software on the configured component orders placed allows a Genesis engineer to access previous job files through MISUMI to reapply existing component designs and legacy knowledge in new applications. This ERP interface benefits both companies, in terms of information exchange, speed and efficiency. As a sidebar, Ricketts notes, there's a synergy at work. "We've seen countless occasions when a part design we helped a customer produce or a modification made consistently by various customers to one of our existing products actually resulted in a new catalog item for us." He quickly added that MISUMI is highly sensitive to proprietary designs and works closely with numerous machine builders such as Genesis to never compromise confidentiality in any way.

During the design phase at Genesis, a design review process is utilized, in which literally every engineer on a project and even some who are not involved directly on the job meet to contribute relevant input to the design strategy and the production process. MISUMI also plays a role here, according to Chris Reinert, because this particular supplier brings its own application engineering expertise from the thousands of similar builders it serves worldwide to the task of assisting Genesis. As Reinert remarks rather emphatically, "We've had many instances during our years with MISUMI when they had a light bulb moment with us or showed us a newer path of least resistance on a design that enabled us to realize substantial time and cost savings. That makes them more than a vendor to us. They're invested in our success." On one job, where a particularly corrosive liquid was contacting a linear bearing rail assembly, MISUMI suggested its then-new low-temp, black chrome plating for the component and the results were optimal.

Pricing on the components, especially those configured by Genesis, is a further assist to this customer, as Reinert explains. "Our design and estimating processes both benefit greatly from the transparency of their catalog pricing, both in print and online with the MISUMI Web Ordering System (WOS). We can literally price out different design approaches, using the immediacy of the RFQ option on the WOS and know what's feasible and what's not. Also, with the ganging of products for shipment, we save inventory carrying costs, as all the necessary components, including those configured, can be delivered to our plant simultaneously and just prior to a build. It would not be exaggerating to say this results in savings by a factor of five over what was our traditional method, just a decade ago." Genesis often utilizes the express shipping options on configured MISUMI parts, but the additional cost is easily offset by the absence of any tooling charge or minimum order requirement, notes Reinert.

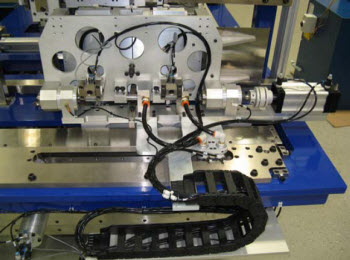

Systems built at Genesis Automation can contain up to 18,000 components and MISUMI content on some of these systems can reach as high as 55%, including shaft, bearings, plates, stands, brackets, ball screws, fasteners, actuators and couplings.

Recently, Genesis was able to successfully "fast-track" the design and build of a prototype test fixture to demonstrate the viability of a new innovative solution to an old problem for a fiber optic communications company. MISUMI was able to provide the majority of the content for the prototype in less time and for less money than Genesis could have manufactured them internally, notes Reinert. The quality and performance of the device helped Genesis earn the contract to build the fully automated system for the customer.

Scott Hale, Genesis president, concludes, "Time saving is a key to our success and the MISUMI business model meshes seamlessly with our own."

Synergy, indeed.

Automotive parts presentation fixture

Total Pieces (manufactured and purchased) – 243

Total Purchased Pieces – 159

Total MISUMI Pieces – 52

Unique MISUMI Pieces – 21

MISUMI Parts which would have been custom manufactured in the past – 11

MISUMI Parts which would have been custom manufactured in the past, their value - $601.20

Estimated value of the 11 MISUMI parts if they had been manufactured by Genesis - $1,540

33% of the purchased parts making up the assembly are MISUMI.