(!)Due to Microsoft's end of support for Internet Explorer 11 on 15/06/2022, this site does not support the recommended environment.

Mon. - Fri. 8 a.m. - 6 p.m.

All Categories

-

Automation Components

Automation Components

Show all categories of Automation Components-

Linear Motion

-

Rotary Motion

-

Connecting Parts

-

Rotary Power Transmission

-

Motors

-

Conveyors & Material Handling

-

Locating, Positioning, Jigs & Fixtures

-

Inspection

-

Sensors, Switches

-

Pneumatics, Hydraulics

-

Vacuum Components

-

Hydraulic Equipment

-

Spray Equipment And Accessories

-

Pipe, Tubes, Hoses & Fittings

-

Modules, Units

-

Heaters, Temperature Control

-

Aluminum Extrusions, Framing, Support & Posts

-

Casters, Leveling Mounts, Posts

-

Doors, Cabinet Hardware

-

Springs, Shock Absorbers

-

Adjustment/Fastening Components, Pins, Magnets

-

Antivibration, Soundproofing Materials, Safety Products

-

- Fasteners

- Materials

-

Wiring Components

Wiring Components

Show all categories of Wiring Components-

LAN Cables / Industrial Network Cables

-

Equipment Specific Cables

-

Cordsets

-

Computer & AV Cables

-

Wire/Cable

-

Connector (General Purpose)

-

Crimp Terminal Components

-

Cable Organization

-

Cable Gland Components

-

Cable Bushing/Clip/Sticker

-

Screw/Spacer

-

Cable accessories

-

Tube

-

Electrical Conduits

-

Duct/Wiring

-

Electrical Wiring Tools

-

Dedicated tools

-

Soldering supplies

-

- Electrical & Controls

-

Cutting Tools

Cutting Tools

Show all categories of Cutting Tools-

Carbide End Mill

-

HSS End Mill

-

Concrete Drill Bits

-

Milling Cutter Insert / Holder

-

Core Drill Bits

-

Customized Straight Blade End Mill

-

Dedicated Cutter

-

Crinkey Cutters

-

Turning Tool

-

Drill

-

Cutting Tool Accessories

-

Screw Hole Related Tools

-

Reamer

-

Electric Drill Bits

-

Chamfering, Centering Tool

-

Hole Saws

-

Magnetic Drill Press Cutters

-

Step Drills

-

Wood Drills & Cutters

-

-

Processing Tools

- Packing & Logistics Storage Supplies

- Safety Products

-

Research and Development & Cleanroom Supplies

Research and Development & Cleanroom Supplies

Show all categories of Research and Development & Cleanroom Supplies - Press Die Components

-

Plastic Mold Components

Plastic Mold Components

Show all categories of Plastic Mold Components-

Ejector Pins

-

Sleeves, Center Pins

-

Core Pins

-

Sprue bushings, Gates, and other components

-

Date Mark Inserts, Recycle Mark Inserts, Pins with Gas Vent

-

Undercut, Plates

-

Leader Components, Components for Ejector Space

-

Mold Opening Controllers

-

Cooling or Heating Components

-

Accessories, Others

-

Components of Large Mold, Die Casting

-

-

Injection Molding Components

Injection Molding Components

Show all categories of Injection Molding Components-

Purging Agent

-

Injection Molding Machine Products

-

Accessories of Equipment

-

Auxiliary Equipment

-

Air Nippers

-

Air Cylinders

-

Air Chuck for Runner

-

Chuck Board Components

-

Frames

-

Suction Components

-

Parallel Air Chuck

-

Special Air Chuck

-

Mold Maintenance

-

Heating Items

-

Heat Insulation Sheets

-

Couplers, Plugs, One-touch Joints

-

Tubes, Hoses, Peripheral Components

-

- Webcode Seach | Series

-

#CODE

- Discontinued Products

Loading...

Case Study: Excitron Corporation

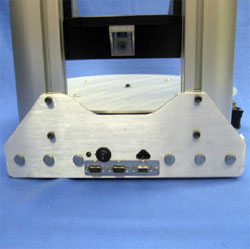

Excitron Corporation's New Motorized Rotary Lift Workstation

Ideal for Automated Assembly, Marking, Quality Inspection & More

High precision, ultra-rigid aluminum extrusions from MISUMI provides strong,

lightweight framework, helped streamline design and manufacturing

Excitron Corporation's New Motorized Rotary Lift Workstation

Founded in 1993, Excitron Corporation designs and manufactures stepper motors, controllers and accessories to create application-specific solutions for machine builders and system integrators. The company's experienced management team has successfully designed and built motorized products and sub-assemblies for various government agencies such as NASA, the Environmental Protection Agency and U.S. Department of Defense. Their customer base also includes a host of other OEM manufacturers including Raytheon, Lockheed-Martin, Samsonite, and Rolls-Royce Norway.

According to Vern Bunch, Excitron CEO and Chief Engineer: "Our biggest challenge has always been having fast, reliable access to the vast array of components required to produce the robust, high-quality mechanized systems, which are the heart of our business – as well as to create precision-built equipment frames and housings. It was not unusual for us to spend hours conducting worldwide searches for reliable vendors who could make and deliver the hundreds of parts we needed to fulfill customer orders."

That's not surprising since Excitron offers customized products built around stepper motor sizes that range from miniscule (10mm in diameter and weighing one ounce) to large scale (NEMA 42, 110mm in diameter and weighing 28 lbs), with the broadest selection of size and torque to fit virtually all applications. In most projects, controllers can be integrated with the motor, which offers a highly desirable combination of extremely small size coupled with rich automation features.

Excitron also makes stepper-motor devices designed for specialized applications, such as precision laser cutting and forming machines, automated pill sorters, motorized digital camera lens controls and gearboxes/encoders used for taking pictures of the earth.

In designing its products, Excitron engineers utilize Autodesk Inventor for all metal working, assembly documentation, product documentation and printed circuit board design. The company also provides custom software and firmware to meet customer specifications. Manufacturing is performed in the company's plant in Boulder, Colorado.

CEO Bunch asserts that his team's design and production workflow has become much more productive since he first discovered MISUMI USA years ago at a trade show in Chicago. "The firm's comprehensive selection of standard and configurable components was a revelation to me," he notes. "It was apparent that MISUMI had successfully conquered the arduous and colossal task of cataloging, indexing and making available key information about tens of thousands of parts."

Bunch says he is also impressed by the engineering knowledge displayed by MISUMI's professional staff, as well as their service-oriented approach to helping customers find solutions to meet specific application needs – even if the project requires custom-designed components.

"Our first MISUMI order was for ball bearing steel slides and aluminum extrusions used to build our XYZ 3D Robot," Bunch recalls. "We found they offered a broad selection of aluminum extrusions and hardware at reasonable prices – with very rapid delivery times. In the 3000-page catalog, we also found a wide assortment of off-the-shelf parts, such as polyurethane rollers and parts that we simply couldn't find anywhere else." That experience was enough to make Excitron a repeat MISUMI customer.

Since then, the Excitron team engineers and manufactures numerous product offerings designed specifically around MISUMI components. MISUMI's vast selection of aluminum frames, extrusions and accessories are a staple for creating equipment enclosures and frames. Bunch and his design team also have become adept at using MISUMI's automated CAD Configurator and fast, easy online catalog and ordering system, both of which help make everyone's job easier.

Bunch estimates that Excitron has saved tens of thousands of dollars in tooling costs by specifying MISUMI components, and has also streamlined product design-to-manufacturing cycle times. "We receive most MISUMI orders in a matter of days – not the weeks or months we often had to wait with previous vendors," he notes. "We have also found that selecting and ordering 90 percent of our mechanical components from a single source rather than multiple vendor's saves huge administrative time and costs. The end result is increased efficiency and productivity."

Looking to the Future

Bunch reveals that Excitron is currently developing an industrial PC that uses MISUMI extrusions both as heatsinks and to provide a protective airtight enclosure. He cites innovation as one of the qualities the two companies share. "We are always working to develop new mechanized solutions based on what our customers tell us they're looking for," he explains. "MISUMI does that, too – they stay in touch to learn what customers need and are constantly launching new products to meet evolving needs."

Excitron Corporation's future growth path is clear to CEO Bunch. "We will continue to research and develop innovative solutions and turnkey machines to meet customer needs. In spite of the current turbulent economy, we believe Excitron Corporation is on the verge of explosive growth, thanks to engineering and manufacturing our products using MISUMI components. We could not ask for a better business partner," he concludes.

The Excitron ZL24-MRT24 Motorized Rotary Table with Z-Lift combines precise 24-inch vertical travel and full 360o table rotation, and can be programmed with extreme accuracy to user-defined positions, directions and speeds to perform various automation functions.

MISUMI offers a wide range of Aluminum Extrusions in standard and custom lengths and a wide variety of profiles. OEMs use structural aluminum extrusions, frames and accessories to create equipment enclosures, workstations, machine bases, robotic jigs and fixtures, material handling components, display exhibits, and much more.