(!)Due to Microsoft's end of support for Internet Explorer 11 on 15/06/2022, this site does not support the recommended environment.

Mon. - Fri. 8 a.m. - 6 p.m.

All Categories

-

Automation Components

Automation Components

Show all categories of Automation Components-

Linear Motion

-

Rotary Motion

-

Connecting Parts

-

Rotary Power Transmission

-

Motors

-

Conveyors & Material Handling

-

Locating, Positioning, Jigs & Fixtures

-

Inspection

-

Sensors, Switches

-

Pneumatics, Hydraulics

-

Vacuum Components

-

Hydraulic Equipment

-

Spray Equipment And Accessories

-

Pipe, Tubes, Hoses & Fittings

-

Modules, Units

-

Heaters, Temperature Control

-

Aluminum Extrusions, Framing, Support & Posts

-

Casters, Leveling Mounts, Posts

-

Doors, Cabinet Hardware

-

Springs, Shock Absorbers

-

Adjustment/Fastening Components, Pins, Magnets

-

Antivibration, Soundproofing Materials, Safety Products

-

- Fasteners

- Materials

-

Wiring Components

Wiring Components

Show all categories of Wiring Components-

LAN Cables / Industrial Network Cables

-

Equipment Specific Cables

-

Cordsets

-

Computer & AV Cables

-

Wire/Cable

-

Connector (General Purpose)

-

Crimp Terminal Components

-

Cable Organization

-

Cable Gland Components

-

Cable Bushing/Clip/Sticker

-

Screw/Spacer

-

Cable accessories

-

Tube

-

Electrical Conduits

-

Duct/Wiring

-

Electrical Wiring Tools

-

Dedicated tools

-

Soldering supplies

-

- Electrical & Controls

-

Cutting Tools

Cutting Tools

Show all categories of Cutting Tools-

Carbide End Mill

-

HSS End Mill

-

Concrete Drill Bits

-

Milling Cutter Insert / Holder

-

Core Drill Bits

-

Customized Straight Blade End Mill

-

Dedicated Cutter

-

Crinkey Cutters

-

Turning Tool

-

Drill

-

Cutting Tool Accessories

-

Screw Hole Related Tools

-

Reamer

-

Electric Drill Bits

-

Chamfering, Centering Tool

-

Hole Saws

-

Magnetic Drill Press Cutters

-

Step Drills

-

Wood Drills & Cutters

-

-

Processing Tools

- Packing & Logistics Storage Supplies

- Safety Products

-

Research and Development & Cleanroom Supplies

Research and Development & Cleanroom Supplies

Show all categories of Research and Development & Cleanroom Supplies - Press Die Components

-

Plastic Mold Components

Plastic Mold Components

Show all categories of Plastic Mold Components-

Ejector Pins

-

Sleeves, Center Pins

-

Core Pins

-

Sprue bushings, Gates, and other components

-

Date Mark Inserts, Recycle Mark Inserts, Pins with Gas Vent

-

Undercut, Plates

-

Leader Components, Components for Ejector Space

-

Mold Opening Controllers

-

Cooling or Heating Components

-

Accessories, Others

-

Components of Large Mold, Die Casting

-

-

Injection Molding Components

Injection Molding Components

Show all categories of Injection Molding Components-

Purging Agent

-

Injection Molding Machine Products

-

Accessories of Equipment

-

Auxiliary Equipment

-

Air Nippers

-

Air Cylinders

-

Air Chuck for Runner

-

Chuck Board Components

-

Frames

-

Suction Components

-

Parallel Air Chuck

-

Special Air Chuck

-

Mold Maintenance

-

Heating Items

-

Heat Insulation Sheets

-

Couplers, Plugs, One-touch Joints

-

Tubes, Hoses, Peripheral Components

-

- Webcode Seach | Series

-

#CODE

- Discontinued Products

Loading...

Case Study: AISIN USA Relies On Configurable Components

AISIN USA's Machinery Design & Build Team Relies On

Configurable Components for Manufacturing Equipment Design

Innovative, yet practical approach focused on product quality and

manufacturability, saves time, costs and engineering resources

AISIN U.S.A. Manufacturing, Inc. has been manufacturing products for North America's light and medium-duty automotive market since 1988. A subsidiary of Aisin Seiki in Japan, the U.S. firm now supplies products to world leading OEMs, such as Toyota, Honda, GM, Cummins, Nissan and Mitsubishi.

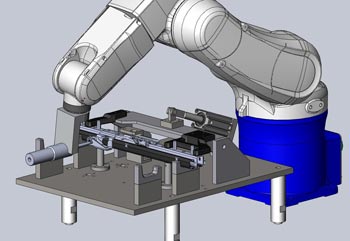

This machine, built around a MISUMI LX actuator, positions

mini-van side door roller components for assembly.

Other components sourced from MISUMI include configurable

plates, slide stoppers, precision posts and fasteners

AISIN employs about 1,400 in its two plants in Seymour, Indiana – which together total approximately one million square feet of space. The company's components, systems and assemblies are used in automobile door frames, latching systems, seating, trim moldings, and more.

AISIN also designs and produces some of its own manufacturing equipment internally. This complex and challenging work is performed by the firm's machinery design and build group. Taking an innovative approach, this team of experienced design and manufacturing engineers work closely together to develop and/or modify production machines and jigs that meet the company's stringent performance and quality standards – both in its manufacturing operations and in the systems and assemblies it delivers to customers.

Linking Machine Design with Product Manufacturing

A typical AISIN machine design/build project would start with a request from a product manufacturing engineer to review and evaluate a new machine or modification, with an eye to design, as well as production and quality requirements.

Eric Peery, Section Manager of Kaizen Engineering, explains the group's holistic approach: "In performing our analysis, we follow a ‘part-out' design philosophy in which we begin with the product being made on the line, and work outward from there. This product and customer-centric approach helps keep us focused on the actual manufacturing process. Our goal is to tailor each machine precisely to our existing production processes, rather than force the process into a machine it's not really suited to. Simply put, our automotive customers expect the highest quality standards, and that's what we aim to deliver."

Specifying Configurable Components

To save engineering and production costs and speed up its machine building activities, AISIN's design/build engineering team has adopted a strategy of replacing custommade parts wherever possible with configurable components from a reliable partner. After hearing about global supplier of configurable components, MISUMI, from its parent company and other machine builders, AISIN engineers decided to standardize on several configurable assembly fixture locating pins found in the MISUMI catalog, instead of producing the parts internally.

Robotic grease application machine uses MISUMI configurable

plates, locating pins, support posts and hinge bases.

The experiment proved successful – Aisin was able to reduce the quantity of its spare parts inventory and the cost of purchasing and storing a large supply of automotive locating pins. Today, the group specifies configurable mechanical components in virtually every piece of manufacturing machinery it creates. Configured parts purchased range from fasteners and stoppers, to linear motion guides, machined blocks and plates, locating devices, rotary shafts, gears and sprockets, bushings, couplers and MISUMI's LX Series linear actuators.

Peery notes: "MISUMI's comprehensive selection of configurable components, along with their online configuration and design support tools, have shortened our design engineering time, while allowing us to configure components tailored to our exact specifications more cost-effectively than we could make them ourselves."

He cited some additional advantages to purchasing standardized configured components versus making custom parts. These include:

- The ability to design and configure a part using MISUMI's Configurator, and then quickly downloading the native CAD file into their SolidWorks CAD software application.

- The convenience of ordering – and reordering – many machine components using a purchased part number, instead of working up a custom design requiring new specifications and engineering drawings every time.

- A significant amount of time saved in the design engineering phase, plus actual cost savings per component, and shorter time to the machine build, thanks to MISUMI's fast response and rapid delivery times.

Examples of Cost Savings

The following two examples illustrate the cost-savings and value proposition of AISIN USA Manufacturing's machinery design and build group's decision to specify configurable components from MISUMI.

Machined Metal Plates. One particular machine design called tor two larger (400mm+) machined plates and ten smaller (50mm-200mm) machined plates, plus an assortment of L- and T-shaped brackets to mount various components. A cost analysis showed that configuring the MISUMI metal plates to AISIN's precise specifications, without additional machining required, saved over $1,800 on the project, which was approximately 4 percent of the total project cost.

Linear Actuators. For another piece of equipment, the group compared the cost and performance of one of MISUMI's configurable LX Series actuators coupled with an Omron servo motor against an "all-in-one" linear actuator they had been sourcing from another major supplier. The cost for the dual-component system was actually $90 higher, but the MISUMI/Omron combination actuator offered ten times the precision and twice the speed. Moreover, delivery time dropped from 6 weeks to 8 days!

Peery concludes: "In this competitive business climate, time is money and quality is paramount – and in these two cases, you can clearly see the configurable component option was the better value."

Contact:

AISIN USA Mfg., Inc.

Contact: Eric Peery

Name, Title: Section Manager of Kaizen Engineering